This thing is dripping oil

well…we are getting improvements…so we are going in the right direction…

can you try some straight line cuts…12" lines

as the 30amp tip seems the issue lets try a couple of things

30 amp tip…new consumables…

20 amps, 0.06 cut height, 120ipm cut speed, THC on, air at 65psi

do another line right beside the one above but only change the amps to 23 amps

do another line beside that one…but at 26 amps…

do the last one at 31 amps…

now write down at the end of each line cut the settings…

then look at the cuts…lets see if there is a change

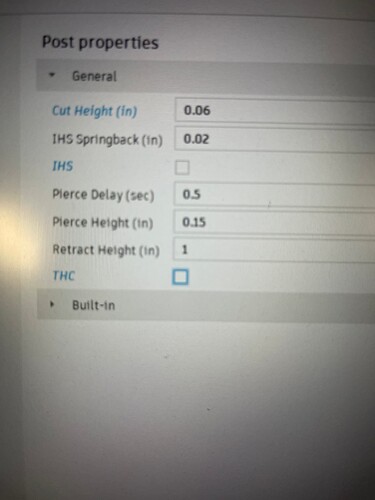

The THC is not what sets the pierce and cut heights. You can turn off the THC and the IHS system will still probe the metal and set the pierce and cut heights. The THC only makes adjustments to the cut height after cutting has started.

Maybe its just the pictures, but that metal looks thicker than 16ga.

I’m sorry I forgot to add that the IHS was turned off as well. I’ve had constant issue’s with the THC. I would pause my cuts multiple times and find it to raise up. I’ve tried it with and without smart voltage on. It’s actually better with it on even though Langmuir says it’s for 14g and thicker. I’m about to make the line cuts that toolboy recommended and post the results here.

its 16g .0600 on the calipers

You cant turn off the ihs unless you do cam without THC. did you mean THC?

The problem with your cut height may be you need to adjust that in your cam. My machine I program .046 to get a cut height of .06.

You may have a few other issues.

In your post process you can do. You need to check your actual cut height though.

Right. I though I mentioned that earlier when I said I paused my cuts and measured. I have it set dead on 0.60. But in the post processor it’s at .062 so I know what you are saying

Honest my bad I meant with ihs and THC turned on…

Are you having air pressure issues?

No pressure issues. Just overhauled the plumbing to 1/2” lines and couplers. The volume is better and the compressor doesn’t come on as much. But still crappy cuts. Hate to say it but I’m thinking hypertherm

I made the switch for duty cycle but can tell a big difference in cut quality… Where are you getting your consumables from?

George. Very reputable on here

True to that. I just looked at my cut chart screenshot. One entry for 16 ga was 28 amp and 70 Ipm. Have you done straight line cut slower?

What Plasma cutter do you have? Looks like your cutting 11 ga? My everlast 82i cuts perfectly at 65 ipm

@ 40 amps .7 delay. If you’re not piercing the plate correctly you are probably burning back onto the nozzle.

16g It looks bigger in the picture. I’m using the RW45

40amp cuts are good but not for small letters. Kerf is too wide. Night and day difference with 40amp vs 30amp

See what happens if you slow it down to like 80 ipm and .7 delay. Turn on the THC control. Cut height at .06 and pierce at .16.

Ok I will try that