Hello everyone, Im new to the group. From Wisconsin and looking forward to making parts for my excavation equipment. I ordered my crossfire pro and wondering what cable setup i need for a everlast 62i?

Hook it up per the instructions to RAW voltage. CNC port to pins 1 and 2 for torch switch. All the cables will come with the table. And by the way, welcome to the jungle(Forum).

Thank you!

ACFrOgBiZgGnIZ_faY61udw-c58QsbPreCBsXLA_OYF1ihr_DCGwP0F1nNeWtQxbT3qOFse26mG6UB9i7AdWW56CarYnZXREt_IM6CALWPZDdnM43xHNu8SpANBgov0=(1).pdf|attachment (74.2 KB)

Here is a cut chart.

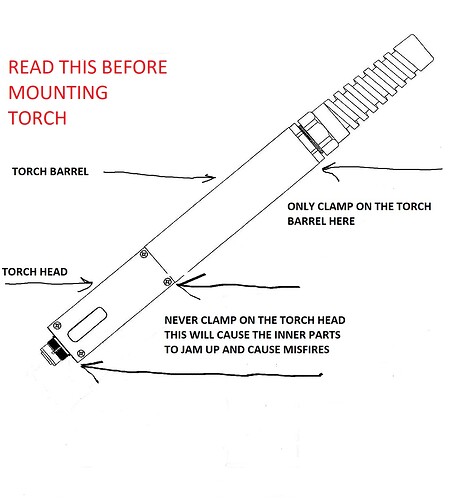

This is how you mount your torch.

Enjoy the read

Welcome to the forum. I see you already met someone that has lots of experience with the Everlast 62i. BigDaddy will steer you right every time but be prepared: He has “forced” me to buy more toys…tools, I mean tools. Tools that I never thought I needed. So be careful around him! ![]()

You know deep down you what these tools. Don’t you, Jimmy?

Roll Tide. Man, those guys give me heartburn.

I had to look up “roll tide.” Never heard that expression. ![]()

Are you sure you are not starting to work on your social media cred? ![]() You know there are many of us that won’t be able to follow you to that side of the street?!?! I hope you get back on your feet and stop pestering those sweet chihuahuas. You are starting to scare me!

You know there are many of us that won’t be able to follow you to that side of the street?!?! I hope you get back on your feet and stop pestering those sweet chihuahuas. You are starting to scare me! ![]()

![]()

I survived chihuahua babysitting. The leg is better. Things are looking up

God forbid anything happens to those dogs. ![]()

![]()

Thanks guys. Bigdaddy bring on the tools! I might just be a bad influence with my collection of “stuff” also be ready i will ask questions… like what are you guys designing in. I’ve been trying to figured out fusion 360.

Impressive!

Start watching Fusion videos. There is a lot of 2D plasma stuff on YouTube. Just concentrate on the newer stuff. Anything more than two years old is the old platform for fusion. It’s really all the same, but it gets confusing.

Thanks for the info. Love the flags

It took me about two months to get comfortable with Fusion 360. Once again, Big Daddy nails it with the advice. Lots of YouTube videos. When you get to the CAM component, TinWhisperer is the king. He has YouTube and twitch channels and stops by here for a bit most days.

Now that I have learned a lot about Fusion 360 (which is probably less than 1% of the programs capacity) I really like it. It depends what you are planning to make as to what program will serve you best. But Fusion 360 will not let you down if you plan to get into anything that is 3 dimensional or with any bending metal projects.

Thanks Jim, looking forward to this adventure. I’m mainly looking to build attachments for my excavation equipment. I have built a few pieces already but it’s time to make stuff look professional.

@Dirtmover911 Welcome to the forum.

How is that possible ? That is a well known expression even here in British Columbia. But we are a bunch of rednecks in rural BC still so maybe that has something to do with it ?

EDIT: and Dr.Pepper is my favorite coke.

I was wondering the same thing. …but I had also assumed the bigdaddy battle cry would be Rocky Top ![]()

All right, laugh it up you two! Are you trying to hurt my wittle feelings? ![]()

I lead a sheltered life…what can I say?? ![]()

Rutgers and Alabama for me. 72Pony

What thickness of steel do you plan on cutting? I would be worried about the duty cycle on 60i. If 1/4 or 3/8 are your metal of choice, you’re probably ok. Start cutting 1/2 or more prominent, which it will do. More significant parts will bring the duty cycle into play.