Will do, thanks

Ahhh!

I found the answer in THC Installation Step by step

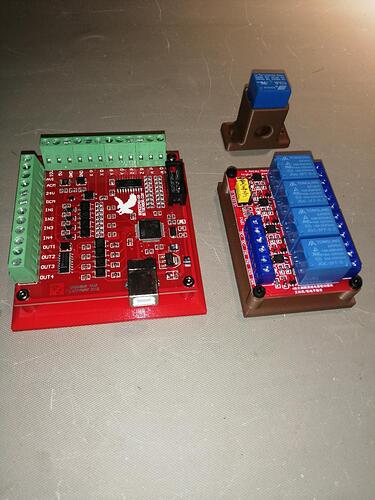

"You can use the relay board if you like, I just used the automotive relay because I ran out of relays.

I only needed a way to kill the 50:1 signal coming from the plasma cutter. My THC needs boot up time from power up, so i didn’t want to control it by the power. That way when you use the software button in Mach3 it will work with no delay. Tooljunkie…"

Some cabinet prep work going on, the THC has arrived in Trinidad but “Delayed in Customs”, so hopefully next week we can start wiring.

NOTE TO SELF: “self, DO NOT ever again try to take apart a ball-screw assembly!” …them tiny little balls pop out of the race and go all over the place! ![]()

LOL! Learning abounds!

I have to tell you I look forward to the amazing adventures of Cletus the plasma wonder boy…

Hahaha! …flattery will get you nowhere!

Still trying to finalize the cabinet layout so there are no issues mounting the THC and the divider board. So will wait to get that in-hand next week before I start drilling holes and bolting down stuff.

I know how you feel he seems to know an awful lot hope to Learn a lot and get 1/10 as good as he is as very least. He is is good .

My THC and some other bits are still stuck in customs here.

Question: The potentiometer that comes with the THC, I am guessing is to adjust the torch height, and therefore is something I will be interacting with quite often? I ask this as I’m trying to decide on a suitable mounting location for it, given the generous amount of wire its supplied with, I’m assuming their intent was a remote location.

Yes, you need the pot to set the THC target voltage, which, of course, translates to cutting height. The value doesn’t change by much, in my experience, but it is different for each type of material you cut (material and thickness). As you can see in my set up (Finally completed my CrossFire mods), I have it mounted on my front panel. @Dicky has his mounted on the side of the Control box so it is relatively accessible. If you cut a lot of the same material in a row, you could easily forget to adjust it when moving to the next material.

You might get away with mounting it separate from the THT03 electronics, it’s a 10K ten turn pot and the THT electronics has pretty good filter, but I can’t attest to it’s noise sensitivity to a remotely located pot.

OK, great, thanks Tom. As usual, good info.

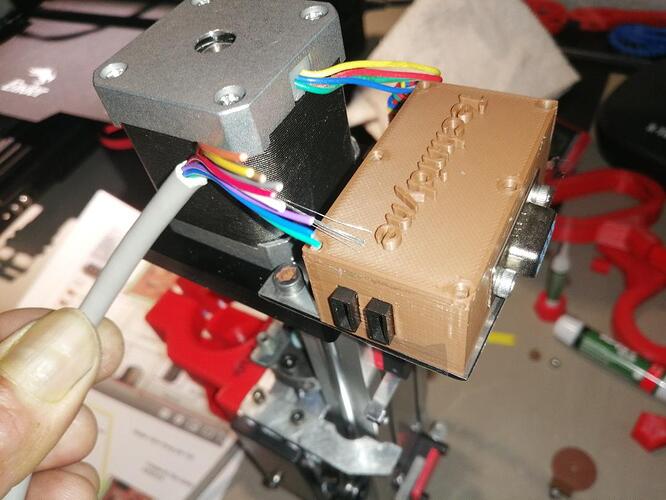

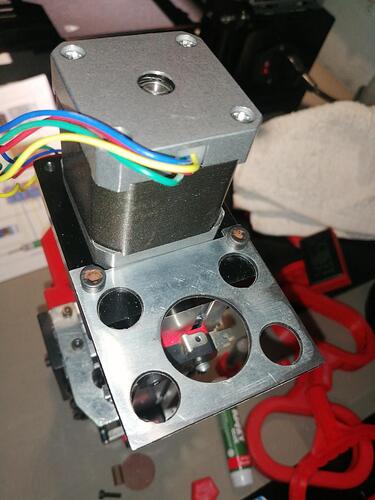

A little more progress today. I’m hoping to get away with a single,shielded, 9-core cable (umbilical if you may) to carry Z-axis stepper motor power, Z and X-axes Limit Switch signals and Floating Z touch signals back to the control cabinet. This will be run up along with the torch umbilical. The DB9 is for the stepper of course and the two RC Servo connectors (I believe they are called Futaba J connectors) are for Limit switches and Floating Z switch respectively (I’ve also got 24V going to those center pins, just in case I decide to go with proximity sensors later on).

You need to get yourself a THC and get on with your life!

Well, the THC was just this minute released from Customs. So I will pick that up tomorrow. They only clear stuff after hours so as to rack-up overtime. Long weekend here as Monday is Independence Day here.

Is your Z axis working and calibrated? I highly recommend that you do that before you fire up the THC. You’ll need that just to setup the THC unit.

Ok, will want to attend to that first of course. But how do I effectively do that if the THC controls it directly and not Mach3? …what am I missing here?

Sorry, I had assumed you read my writeup where I described the cabling that can be reconnected to bypass the THC and send the Mach3 Z pulses directly to the stepper drive.

Because that is so much easier (and useful in and of itself), I’d still recommend wiring in a temporary bypass to connect the Mach 3 step signals to the Z Stepper. This way you can set up Z without dealing with potential THC interface issues.

I will certainly go read that, thanks