So as to gain some consistency, all my Crossfire build notes and mods will be posted right here as I go along.

Whipped-up this little trolley for the CUT60 this morning (love the smell of flux-core in the morning) I’m thinking will mount the Motor Guard filter on the backside and my intended THC box in the front right under the CUT60 panel.

Plan is to get all the THC, Z-axis stuff and XL Kit in advance. Get the basic Crossfire up and running, cut some projects, gain some experience, then add the XL, limit switches, etc. and decide how I want to setup my Z and THC hardware based on my workflow and the physical constraints.

So, got up early and did some cleaning in the workshop and created the floor space I need for the crossfire (including the XL mod.)

Space! …the final frontier!

Seems something’s missing… what could it be???

Damned right! LOL!

It’ll get there soon. Just keep playing with the software. The table pretty much runs itself with a click.

Looks like an operating room without a patient! (or a bed for one!)

Better that then that room servicing you!

Hey Tom

Maybe a stupid question, If I’m going with the proximity sensors and THC3T- 02 step/dir, do I still need a floating Z-axis and microswitch home? What’s your machine setup like? Trying to accumulate the bits and pieces as funds become available (I’m patronizing the bar down the road less …LOL!)

Not a stupid question at all. So, on the surface, I would agree, IF you have prox sensors that sense ALL the material that you’re going to cut (even if variably - that can be taken into account with the tool setups), then, no, you don’t need Floating Z. If you have a Z hard stop that doesn’t break when over driven then, no, you don’t need Z Home. The plus side is obviously non-contact sensing so you won’t deflect the material.

Here is what I think are the downsides of Prox sensing:

- You can only sense at specific points, none of which are directly under your torch. You MAY have patterns, when cut out, that leave gaps that can’t be sensed. Who knows? Maybe you can program around that.

- In my case I have an angle iron set up as a fence along the Y axis (X min) and, by necessity, it is a bit thicker than 11Ga material. So… if you’re cutting thinner material than, 3/16, for example, you will get false reads where the Prox sensor overlaps the fence. Is that tragic? Not too much if your THC is working properly and the prox sensor has clearance over the fence.

There may be other issues, but that’s what comes to me immediately.

Ok, cool! thanks. Will shoot for floating Z and play it by air (no pun)

My Crossfire is here and Customs is taking their time clearing it (the waiting is killing me!) Hopefully it will be released in a day or two.

A range of consumables for the IPT60 torch, came in from George and cleared customs today. Now to figure out when to use what LOL!

Still shopping and acquiring stuff for my eventual Z-axis / THC modification, quite a bit of stuff in-hand already.

Let’s see… at a tip a day, I count that you should last maybe two weeks with that stuff! Good job!

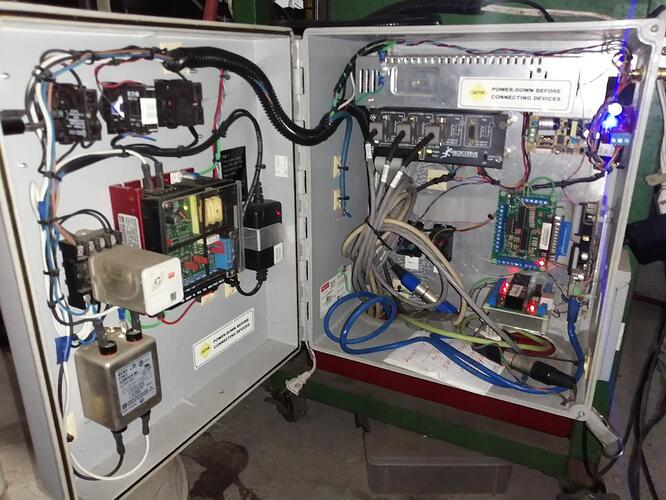

Well along with my Z-axis / THC mod, I’ve decided to build myself a completely new control box and leave the OEM control box unaffected. So I ordered all the goodies, power supplies(36V, 24V/5V), Red Board, Stepper Driver units (I have already), Relays, connectors, the THC3T- 02 step/dir, etc. Looking at a polymer or fiberglass enclosure with hinged door and latches big enough to house everything, but thinking a metal enclosure (though pricey) may be better from a electrical noise mitigation perspective.

This is a Hoffman fiberglass control box I outfitted some years a go when I turned my Grizzly Mini-Mill into a 4-axis VMC.

Panel lettering was done with my homebrew CNC 3W Laser / Rotary engraver.

Feel free to checkout my other exploits on YouTube (9z4clb)

What was your process for ‘burning’ the lettering, especially with a 3W laser?

Black laminated plastic sheet (the top lamination is extremely thin) used for rotary engraving nameplates. CamBam to draw and generate gcode. Ultrasonic cleaner bath after burning. I use it for a lot of custom stuff for the hospitals.

Well, they popped the seal on the container today, Customs will tear into my crate tomorrow and it should clear by Monday.