I still need to drill in wedge anchors for the feet, I’ll do that tomorrow after work. It’s all done though other than that and plugging in the automatic tank drain valve. I tested it, it does work. There were some installation issues that I will cover in the install video I’m going to edit when I get time. The wiring from the factory does not match the wiring schematic in the manual, and the tank drain line is so close to the floor that you have to tilt the entire compressor about 8" to get enough clearance to thread on the automatic drain valve. The compressor is a monster, I’m a little disappointed that there is no manual that comes with it and that the wiring was so out of whack on the schematic. Just low hanging fruit that is super easy to fix. Anyhow, it’s quiet for a compressor this large making this much air. Quieter than my 5HP Sanborn that was making about 30% of the air at a lower pressure. It’s still loud though, you’re not having a normal conversation with someone if you’re standing anywhere near it. Also, the oil pump was making 140PSI when I first turned it on, it slowly came down to about 100PSI after running for a couple of minutes. That had me nervous. I did call their support line because of the wiring, got US based help within 2 minutes and they walked me through the wiring like it was nothing. I have to say the support available for this is next level. I’ll post the installation video when it’s done. I used the engine hoist I built to get it into position, this thing is just unreasonably heavy…it literally weighs as much as my Harley (Road King Classic) did…790lbs vs 806lbs. The keen eyed may have noticed I disconnected the Silent Air intake system and mounted it to the wall, this was both for space and ease of access to the intake filters.

I forgot to mention, it pulls 59 amps at 244 volts on startup but then settles into 34 amps once it’s going.

That is an impressive number!

That’s just on startup though, it settles down to 34 in just a few seconds. I think I have it on video, it will be in the install video when I get it done.

I have that same compressor in 7.5 hp I never fastened it to the floor. Just sets on rubber pads, it’s never moved.

I’m pretty sure it would be fine but they mentioned that the warranty could be void if it isn’t bolted down. I didn’t get the impression talking to them on the phone that they’re likely to look into something like that but I’m just gonna do it anyways. What was your oil pressure looking like when you ran it the first time?

I take that back mine is not the same as yours (same company) that are different my is splash not pressure lube. And your is probably more top heavy than mine, makes sense to bolt it down.

I put some bolts in after work today, that automatic tank drain really makes you jump when it goes off. I was on the fence between the pressure lube and the splash lube, on the one hand the pressure lube definitely will get oil spread around better, on the other hand the splash lube system will NEVER fail. The pressure lube system came with an oil pressure gauge which is what tipped me over to that side of the fence ultimately.

That is what mine did, for the first 12 times, when the garage was quiet and I walked by. ![]()

Then it just started to irritate me. ![]()

But now, since it only cycles when my compressor is running, I never hear it. ![]()

If it wasn’t so low to the ground already I would put a muffler on it, but being that it’s a drain and needs to be lower than the tank I don’t think there is any way to get a muffling system on there.

If it gets to be too distracting, I’ll trade you my Campbell Hausfeld 60 gallon for it. ![]()

Seriously, that is one nice compressor. That should be a “one and done purchase”.

I have a line on mine that goes into a 5 gallon bucket with a lid on it.

I put one of these on it and it does cut the sharpness of the sound. Since it cycles regularly, there is virtually minimal moisture so I just have it lying on the floor.

They are very small and all plastic.

.3 hours on the meter and the pump has sprung a leak.

The puddle on the floor

Where the leak was spraying onto the intake hose

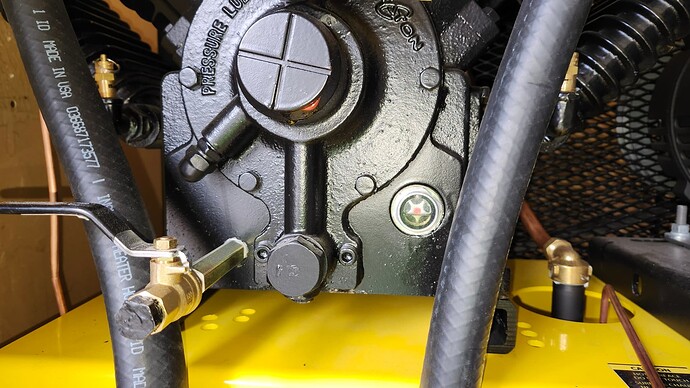

Where it looks like it’s leaking from

From a broader view, you can tell it’s spraying because nothing is leaking onto the mounting plate which also explains how it’s getting onto the intake hose and that far out on the floor.

I think it’s leaking from the oil pump pressure relief/adjustment valve. I’ll be calling EMAX support on Monday but for the time being the compressor is offline. Luckily I’m in the middle of a laser engraving project (making challenge coins for the Marine Corps birthday) that has me away from the plasma table for the next week. I think this is because the pressure is running too high, when it first starts up it’s running at 140 PSI of oil pressure and gradually drops down to 110 PSI which is also too high in my opinion.

I agree, my old shop had a 1950’s Quincey that had pressurized lube and I think it ran at about 10-15 psi

Curious to see if that 110 psi pressure is correct.

So that leak was oil, not water correct?

Correct oil not water

Turned it on to find the leak, took 2 seconds…

Looking at it, I don’t think that’s the relief/pressure adjustment, I think it’s the gear housing because I’m pretty sure this is a gear pump. I’ll find out for sure when I talk to them Monday. Should be an easy fix though. My guess is the fix will be adjusting the pressure relief valve down to something like 60PSI and resealing that cap. Probably the high pressure blew the RTV out in the first place.

Bummer when brand new equipment shows failure ![]()

Well…the brand new compressor needs a new pump. I literally have .3 hours on it. They are sending someone out to replace it, waiting to hear back now. I adjusted the relief valve all the way down as far as it would go and now my pressure has the gauge pegged off the scale. This is not what I expected for $4700. I’ll update this thread as things go forward.

You know Kevin, I am torn with such a situation. I want to say “I hear you. Thanks for the update.” But if I click the “Like ![]() ” button it is like I am saying “I like what happened in this note.”

” button it is like I am saying “I like what happened in this note.”

So I had to write something instead (no like button this time): “Sorry, buddy, for your situation.”