What’s everyone doing for chip evacuation when it comes to large deep pockets while machining. I get massive amounts of build up inside of deep pockets having to pause my op and clear out all the chips inside then resume. I thought about setting up an air system coming off of the spindle housing but unsure at the moment. Would be nice to let the machine run freely and just have to worry about chips in the tray.

I’ve considered running an air blast hose and nozzle to the other side of the spindle, with a valve on the front of the machine to let in air from a precharged tank.

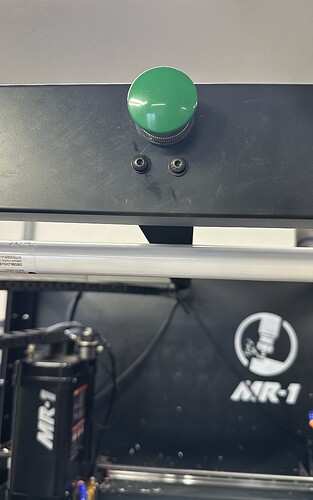

I have this setup for just that reason. Manual valve mount above the doors and then the back nozzle is for the air. If I end I doing a production run that needs this to be automated I can switch the valve to electronic and than just put it on a timer control that would start when running.

Do hope that in the future Langmuir adds option for other output control that could be setup for controlling the air blast.

I’ve got an air gun with a small enough nozzle that I can fit it between the doors and give a little manual air blast to blow chips out.

I also open up the coolant valve enough to blast them out if machining wet.

Last alternative is, I machined an aluminum fan that fits over the collet nut. I can slip it on and lock it down with a set screw for some moderate airflow. It doesn’t do as good with bulky chips in the bottom of a hole, but if the chips are flying off the mill far enough it will displace them pretty decently. There is also CAD files for a 3d printed ones as well that work pretty decent.