Hello everyone , German guy here

i just bought a crossfire pro and asssembled it. Now im getting into programming the G codes.

I watched Langmuir´s guide and a lot of youtube clips an up to this point everything seems to be understandable (still waiting for my Hypertherm to arrive to make first cuts).

Im just curious in which way you change your feedrate when you cut different thickness of steels?

Do you create different tools for every thickness and select them dependend on what to cut or do you change the parameters in Fusion´s setup or do you work with the offsets in Firecontrol?

It would be nice hearing form some guys with experience what the best way to go is.

Thank you in advance!

1 Like

Great choice ! Welcome to the forum.

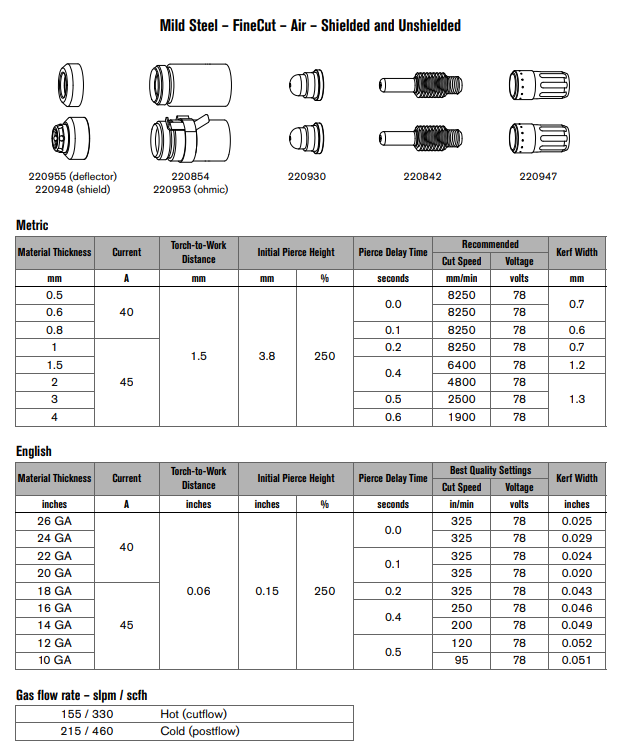

Which one? You/we can download the operations manual in the meantime. In the manual will be cut charts with all the parameters for different materials and thicknesses.

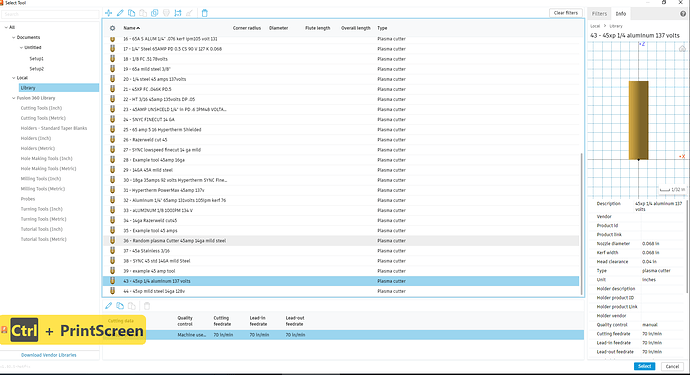

By Creating different tools in you Fusion 360 local library for each different material thickness and type that you use.

yes

What are you looking at cutting mostly and I can run through creating a tool from the Hypertherm manual in fusion 360.

4 Likes

I smile at your title of this topic: Changing speeds and parameter the “easiest” way.

After you have done it once or twice it is all “easy”. It is just getting past that first step.

You are in good hands with @TinWhisperer. He has many nicknames but one is “Manual Man.” I defy you to name a piece of equipment that he is not able to produce any page of the manual is less than 4 hours. Sometimes he needs to trudge through the rows of boxes in his storage garage, but he will find it. He has been known to buy up old equipment just so he can look at how it was assembled (First Gen Crossfire OG). Here is an exclusive photo of his garage:

1 Like

Well, you know, sometimes those directions are confusing:

2 Likes

Hey, thanks for the quick reply!

I bought the powermax 45 XP with the CPC outlet for easy connection to THC.

Okay downloading the user manual is a good idea. I will have a look for that later on.

Thank you very much for sharing your opinions!

I will mainly cut mild steel , but i have a lot of projects which vary from 1 - 5 mm thickness.

Im working in the repair industry so jobs with stainless or aluminum material will come in pretty fast also. Thats because i bought crossfire pro, to be independet from other manufacturers and have a better reation time after receiving a request.

Im sorry for my poor english btw!

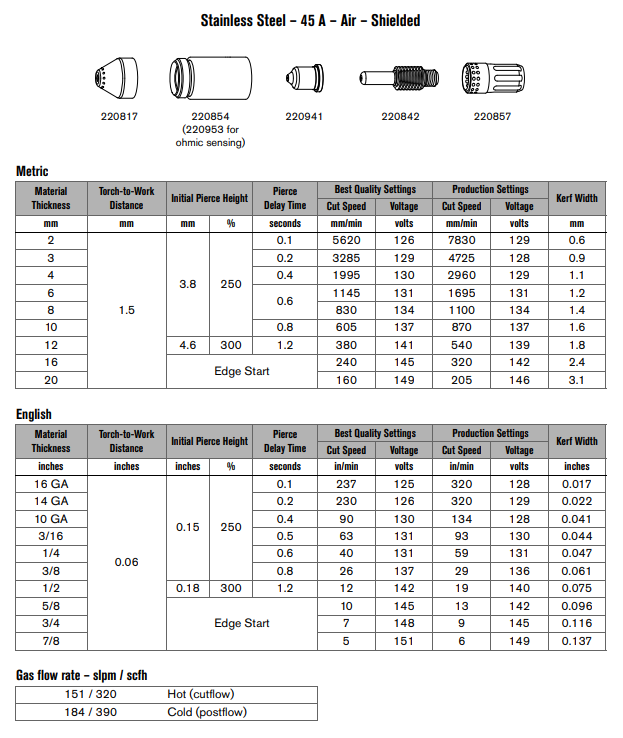

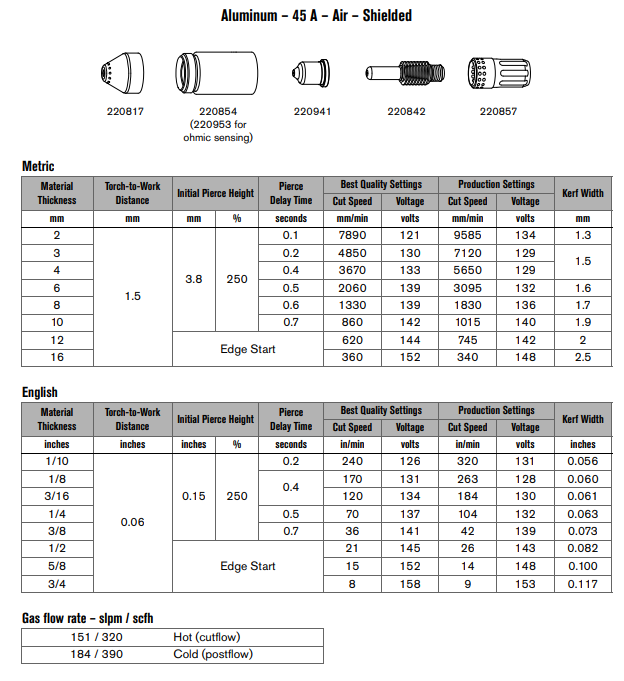

You might find this thread helpful as it has copies of the cut speed for Hypertherm 45XP for Mild Steel, Aluminum and Stainless. There are a few other points of discussion offered by others to help give context.

https://forum.langmuirsystems.com/t/purchased-hypertherm-xp-45-what-settings-in-the-fusion-tool-library/31750/2

It sounds like you stay pretty busy. I attempted to attach the PDF file to this posting but it was 18 MB in size and the limit is 8 MB.

Here is a link to the manual on the Hypertherm website: https://www.hyperthermplazma.hu/wp-content/uploads/2019/11/Hypertherm-Powermax-45XP-kezelési-útmutató-OM_809240_R3_Powermax45XP.pdf

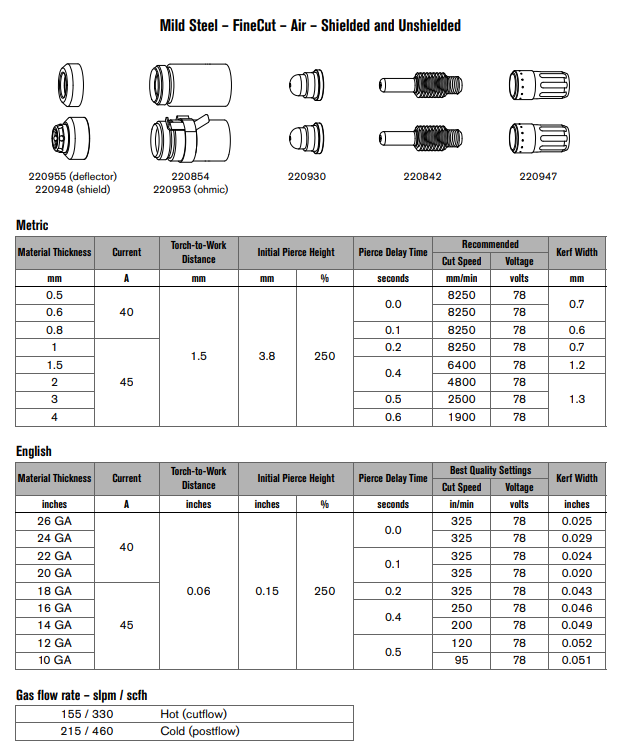

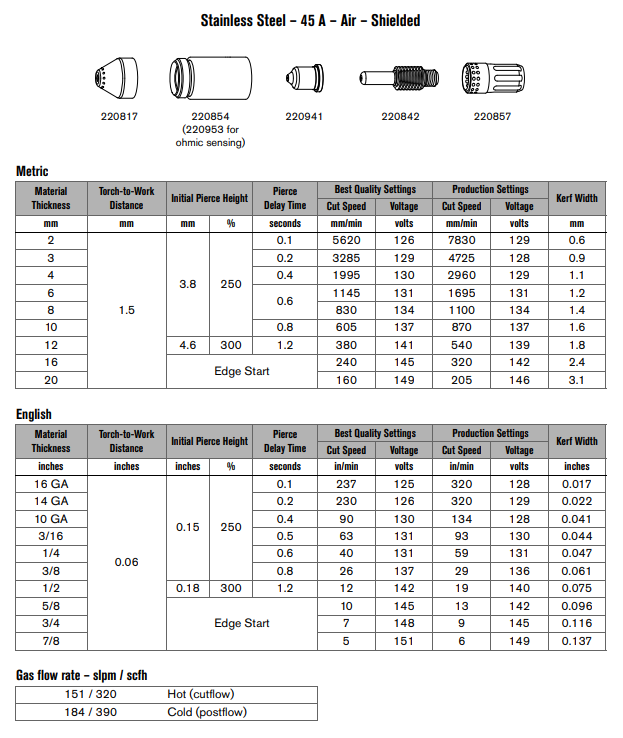

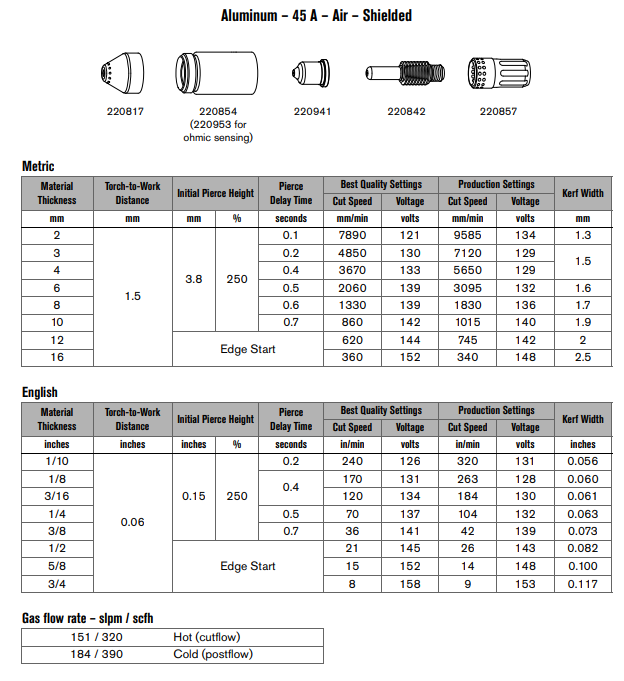

Since I was not able to give you the manual quickly, I will include a few of the cut charts for Hypertherm 45XP. These charts begin on page 130.

Your English is better than most of us! Welcome to the forum.

1 Like

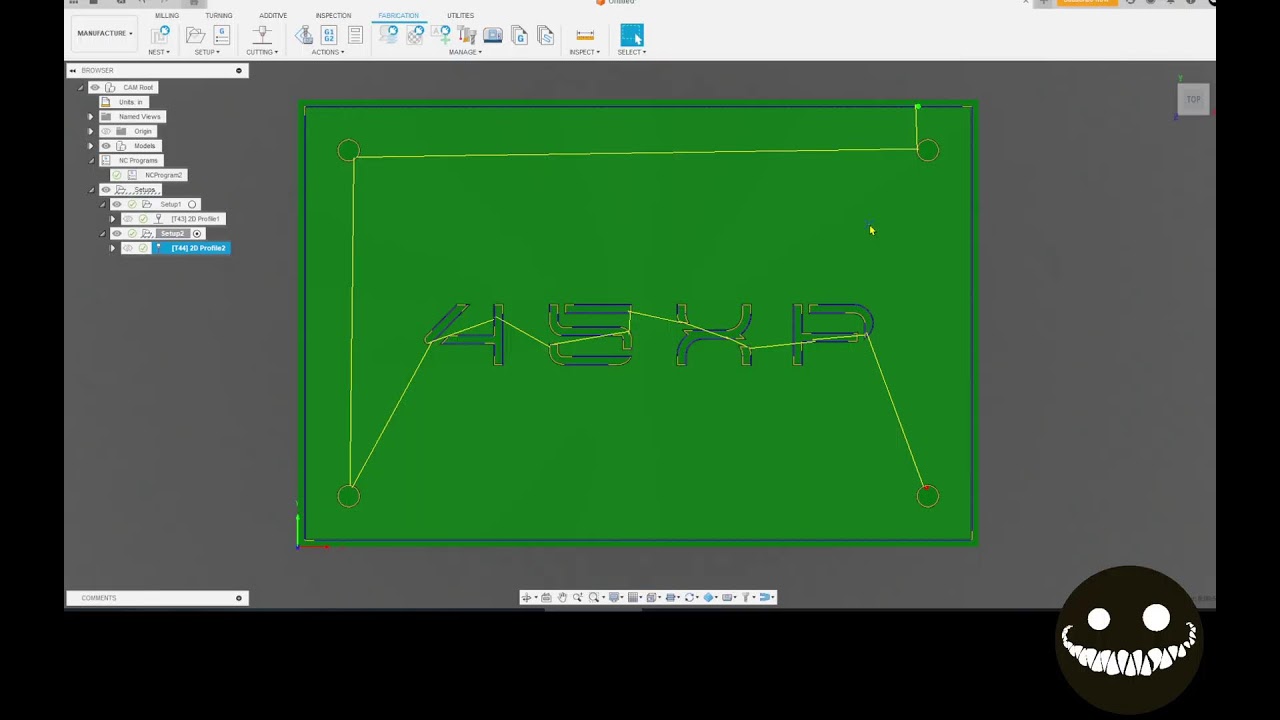

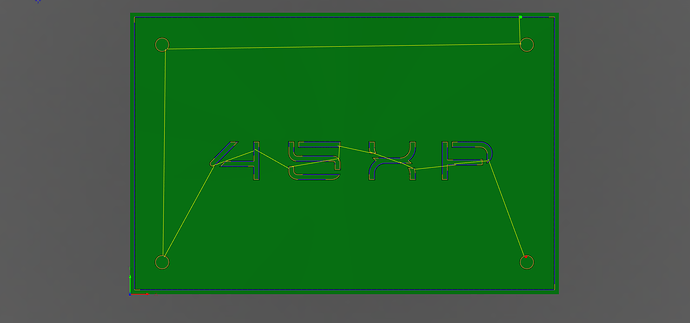

@PascalPrott I will do a video of setting up a couple tools

45 xp test.f3d (244.0 KB)

2 Likes

Hey man,

thank you very much for the turorial!

It really helped me to get a better understanding of the workflow.

And i really appreciate the effort you put in that video!

2 Likes