Is the factory breakout board on a CF capable of integrating with a THC/ Z-Axis if the other required hardware was present? (i.e. Z axis, stepper, motor controller, THC controller, etc?)

Check out my post here. It should answer most of the questions you should have about a z axis.

I read your post, which is excellent, but what I’m still shaky on is how and where the inputs from a THC are processed by the BOB. My understanding is that with the limit switches you installed, you provide upstream feedback to Mach3 via the BOB and then it (Mach 3) sends the stepper commands back to the motor controllers via the BOB.

Would a THC provide similar inputs to Mach3 and then it would command the Z stepper accordingly using the same upstream/downstream flow or would the THC provide inputs directly to controllers via the BOB?

I’ve been trying to research THCs and I cannot figure out if they are setup for simple limit control based on voltage (bang-bang) , if they use some kind of a PID loop, or maybe something cool I don’t even know about yet…

Thanks

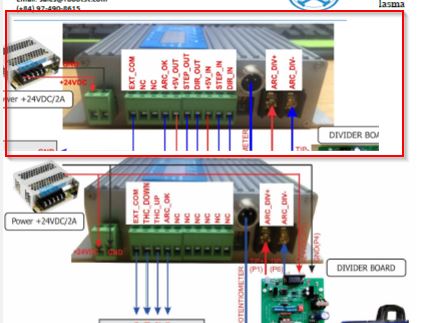

Most thc’s I have seen send an up or down signal to mach 3 via the bob to adjust the height. The one I was looking at, which I think would be best for my setup is the proma thc sd. This one is for stepper motors. It actually controls the z axis stepper independently of mach 3 and the bob.

I would think they check voltage then adjust accordingly, probably something like, If setpoint is 100v and voltage is at 95v, then output signal for change in height. I would assume that this happens every .5-1 seconds and also has a deviation from setpoint parameter.

I haven’t read too far into thc at the moment but it is something I will do when I’m ready to add a thc to my machine.

Addind a THC to the table is my next winter project… Hope you will open the trail before me, you seem to be good in electronics!

Hope you will open the trail before me, you seem to be good in electronics!

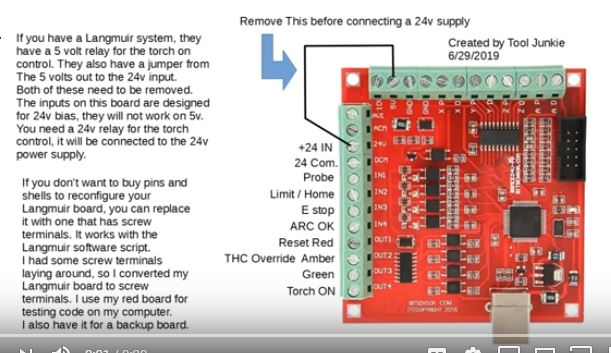

Hey Burgs04, I found this diagram for activating the inputs and it mentions disconnecting the jumper from the 5v to the 24v, which is a no brainer. I don’t understand the part about the reed relay, or how to “disconnect” it and still have it fulfill it’s purpose. If you could educate me, that would be great! I will have my THC in a week hopefully and plan on installing it. I’ll definitely post my progress. Thanks in advance!

based on the information you have presented here. Langmuir has a 5 V relay used to turn the Torch on.

The relay will need switched out for a 24Vdc relay. (the 5V to 24V jumper on the Langmuir setup is there to feed 5Vdc to the relay that’s my guess). I think the 5V reed relay is hidden under some black heat shrink a few inches away from the board. tool junkie listed some 24v 40A automotive style relays in his parts video (same one the image you shared was pulled) as well as some female blade crimp on connectors. If you cut the leads off the reed relay. Crimp on the connectors yo can connect the wires to the automotive relay easily. Pull the jumper, feed 24V to the +24V in and all should be well.

I must say I haven’t tried this. All the information I have given is speculative. Try it at your own risk. Also modifying the wiring/controls of the unit may void any kind of warranty you have/had on you system. Proceed with caution.

With that out of the way… Good Luck! Post pics and comments if it works or if it goes up in flames (so we know not to copy you!)

Bruce

So my question is, why cant I just disconnect the relay wire from the 24v pin, and connect it to the 5v pin and sever the connection between the 5v and 24v pins? I believe currently, maybe in my ignorance, that the 5v pin is supplying power to the 24v pin… I believe this is what I currently have… I understand that to activate the inputs the 24v pin will require 24v.

As for the warranty… Theres only about $80 in electronics inside that cabinet… I’ve already ordered 2 new usb controller boards to use for bench testing, and have a spare in case something did die, then I won’t be down waiting on parts…

The reason you can’t just change the voltage for the 5V relay is that the transistor/mosfet on the board that turn on the relay trigger the voltage that is on the +24v. Langmuir was able to fudge this with a 5V relay by using the jumper. This works because they don’t use any of the digital inputs and only a few outputs. As others have noted you have to feed the board +24V to get the opto-isolators to work correctly.

The board was designed to run on 24Vdc. It can be made to work on 5Vdc but you lose some of the functionality. 5V relays will not last long being triggered by 24V. They might work a few times…maybe just once, but their time on this earth is short ran that way.

Thank you for the explanation! I’m a novice when it comes to electronics, just one thing I havent found the trick to grasping yet! Yet! LOL, I really did just buy the big massive electronics for dummies book!

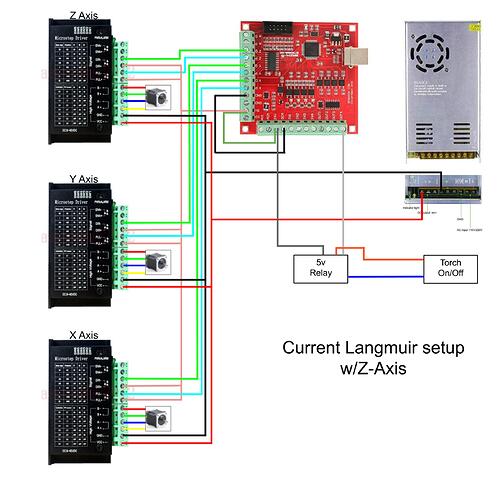

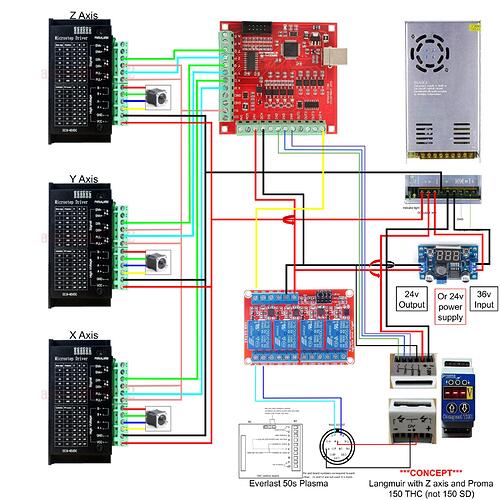

This is what I have finally come up with, hoping my THC gets here soon, air dryer arrives today! Another member, burgs04, has said that this is how he would wire it. I was just guessing and looking for confirmation.

Hi Dicky, I noticed you are going to use the langmuir USB bob for your THC. The Bob doesn’t support the THC in Mach3. It will go as far as lighting the Torch up and down LEDs in Mach3

But the software will ignore it. You will need the proma 150SD for that bob. The problem is no one has written the script in the software to support that usb bob. The SD isn’t controlled by Mach3. Thought you would like to know.

ToolJunkie…

Well, that doesn’t sound good, I got this th!s thing all wired up! I’m ready to put it to the test! One thing I can do is write script… Know of any examples that I could look at? I’ll write the darn code! Got a lot of money and time put into this so far…

What about the chinese redboard? I have 2 of those…

So I had an epiphany after I ordered the step/dir controller from the same manufacturer… I was looking at the wiring instructions and noticed that the pins on the S/D model are not used on the Up/Down model and vice versa. The arc ok is common, and so are the rest… I figured that these are the same boards, the only difference is how you wire it… And it worked… So this model is capable of both modes and works great! The only downfall I find is that when in step mode, the Z axis does not move, and in continuous jog mode it does not move under 58%, although the DRO thinks it is moving and the numbers change. I had already planned on using the probing method (because I have a floating Z) to set my Z zero, so this doesn’t bother me so much… When running in THC mode, the Z axis moves, but the DRO does not change, again, not an issue… Hope it helps!! Does the proma do the same thing with the jog modes?

Im using the THC3T-02

Sorry, I can’t help you on the code, I’m and electronic hardware guy. I ran into this myself, most of the usb bobs

don’t support THC. the red boards are the same as the langmuir. If you write the code it would be great.

I don’t know why they left out the THC. They support Probe, Limits/ Home and Estop for inputs,

and any four outputs you assign in Mach. I can give you a hint where the problem is, The Mach3

is expecting the Torch on, Torch up and torch down to be on the parallel port on Pins 10-13 or 15.

The usb bobs input pins are 1-4. I know how you feel on the money invested, I did the same thing.

I talked to the people where I bought my, Proma 150 and they explained the code problem and let me exchange my proma 150 for the 150SD. It works fantastic, you do have to get everything set up correctly. I cut alot of thin metal that moves like crazy. I was cutting some parts for my buddy at work,

and it was going so well I made a short video of it. I thought everyone with a langmuir should see, that it can be done. I put it on youtube and everyone wanted parts lists and drawings . If you fix the code problem I hope you will share it like I did. There are features on the Mach3 THC control that are not on

the proma, but hey it’s not a $20k table. It works great for everything I am doing. The Z axis alone saves torch tips. Hope this helps. ToolJunkie…

It looks like the same setup the proma SD is using, I don’t have a problem with Jog mode with the proma.

Seems to cost alot less than the Proma, good find. If it doesn’t talk to Mach3 you will have the same control limitations as the PromaSD, that’s ok, it will still work for 90% of your projects. you will love it.

I would like to see your setup when you get it running.

ToolJunkie…

I’m still going to pursue the code, I went through the programmers reference guide and have a few ideas… I would absolutely share if I find the solution. I’m guessing the jog problem has to do with something on that board, it’s obviously a lot bigger than the proma, seems like it may eat a little of the signal before passing it through… I’m not an electronics guy, so I’m just guessing… I’ll take what I can get at the moment… Still have to install my 220 before I can cut, tried on 110 and it just didn’t like it… At least not on 1/8" steel, kept popping the breaker… I have to run a new line from the house to the garage sub panel, so it’s gonna be a task!

I hope you do figure something out with the code. It’s funny I work in a building full of

Software engineers, any one of them could do it, but I can’t afford to pay them to do so. They bill out at $150/hr. It was cheaper for me to buy the stand alone THC.

Tooljunkie…