Which is better to start a small hole cut . A Tangent or a Perpendicular start for a lead in ?

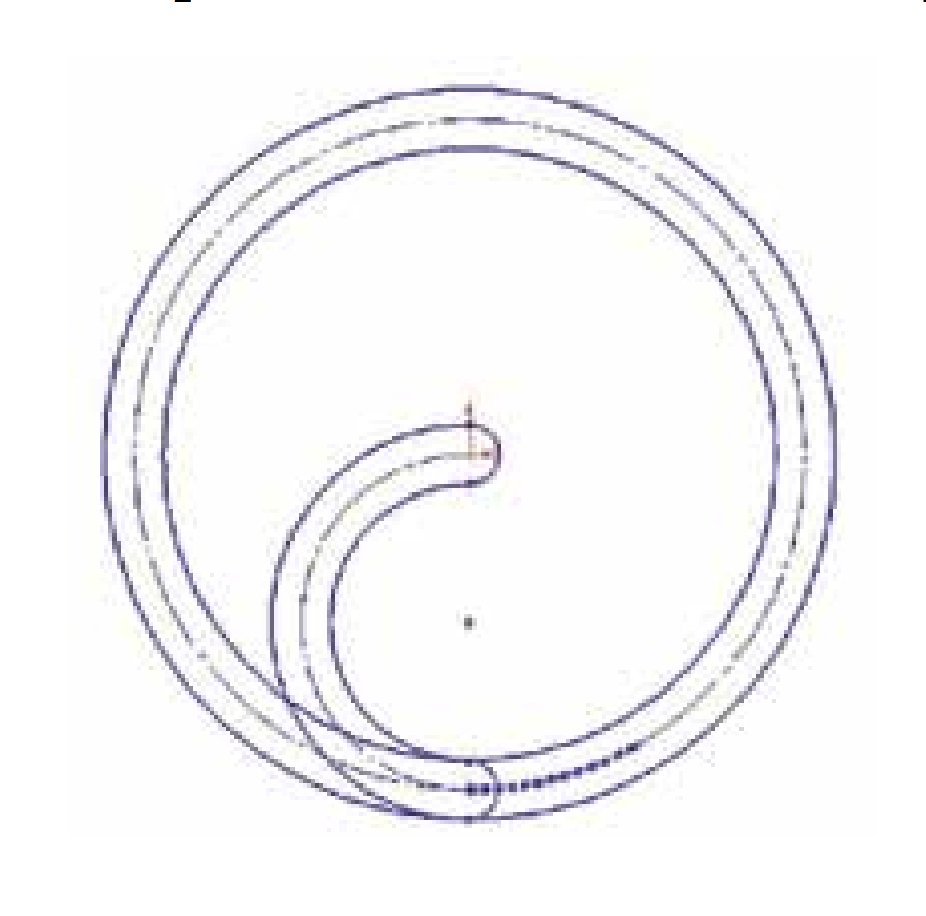

Semi circle to tangent in a ideal world.

Hole diameter and the material thickness really does affect what the optimal parameters for a lead-in, lead-in radius, lead in speed, reduced radius cutting speed(feed rate optimization), finishing overlap

and potential lead out radius and lead out.

What would you recommend ??

What size hole diameter?

what thickness of material?

what type of material?

A lot of the time I might default to

Leading radius of .02

60° lead in

Leading of .05

The same for Lead out

Finishing over lap of .03

But I would change this up depending on the diameter and thickness

1/2 inch hole 1/4 inch cold rolled metal …

No lead in

a .25 lead in radius

Reduce feed rate by 60% for the hole

Finishing overlap of .03

That would be a good start to get a semi circle tangent lead in.

Thanks… For the advice

I think we’re both trying to answer the same time

I think our message timing kind of got off