I was moving a larger piece of material a couple inches over on top of my table today and the whole table tipped in the direction of the control box and of course all the water dumped over on top of my control box. Now after drying out the control box I am getting jerking movements on the x-axis randomly. I ran my program back over my cut three times and it does it in almost the same locations every time… Luckily I keep a blue tarp over the side of the table where the control boxes but it still got pretty wet opened it up and inside was actually pretty dry connections were all soaked on the exterior…

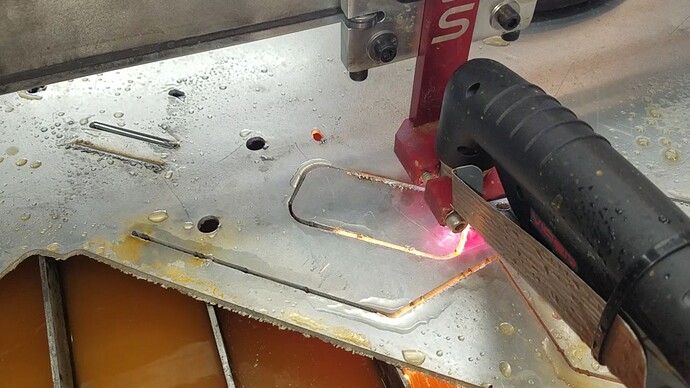

You can see in the pictures above along the lines of the cuts where the torch is stopping/pausing and then continuing to do it over and over again… I cleaned gantry and lubed it and still doing it.

The wheels are crap and I hate them. I don’t move my table around the shop since it is now dialed in and perfectly level. When I have some down time I plan on removing the casters are welding on plates with bolt heads sticking up for adjustment. I had a wheel fall off and the first thing I thought was what if the water table would’ve been full.

I plan on doing the same thing soon I don’t move mine more than a few inches to reposition…

I am beyond pissed. I was moving my crossfire today and the wheel by the controller box came off and my table was full of greencut and went all over the control box. green cut is not cheap and took me several weeks to import it from Canada. Looks like im going to need to find better wheels and weld them on

feel your pain brother…

I am planning on moving my control box. Either under the table or on a wall… Accident waiting to happen…

I saw this post and became curious about this issue. I tested it for myself by installing a caster insert and caster into a leg tube and clamping on the caster in a vise, then leveraging the leg tube to see if I could get the insert to pop out.

As can be seen in the picture, the caster stud bent and the insert is still in place.

When i installed the insert, I used a deadblow hammer to first seat it. Then I used a ballpeen hammer directly over the female threaded insert to further drive the insert into the tube (and thereby initiate preload between the sheet metal flange and the end of the tube).

Therefore, I don’t believe this is a design issue , especially since the caster inserts are an off the shelf item that are intended to be used with casters. Instead, I believe it is an installation issue, and we carry some of the blame because the assembly video does not show the second step of further preloading the insert with a ballpeen hammer.

I will have to try the ball peen hammer method, because I too have had casters pop out when attempting to move the table and was also at the point of going to modify/weld casters to mine.

Give it a few food wacks with a ballpeen and let me know how it goes. sorry for the inconvenience!

If possible can you tell us the diameter of the insert? We are wondering if there is a defective batch…

@langmuir-daniel Thank you for your response, I am out of town at the moment but when I return home will grab a caliper and let you know!

@langmuir-daniel I would like to be able to help you with a measurement but I just got mine all put back together and level back out again don’t really want to take the wheel off. Plus the table is full of water. By the way I did not mention in my previous post but before I move this table I always check the wheels to make sure that they are putting the right direction so it is not like it went sideways against the wheel. My entire wheel Castor and enter all popped out.

I just assembled my table today…(took a couple weeks to get to it. Darn job!!)

Anyways, I encountered the same problem of wheels wanting to fall out. I shouldn’t really say “fall” as that is not the case. It seems with the axle of the wheel being off center from the rest of the leg and insert, any leverage against the wheel, either from the side or in line with the wheel is enough to start the disassembly some of us have encountered…

I got the luxury of reading of some instances of this happening ahead of time and was watching out for the issue… I seated the insert with dead-blow hammer as indicated and then further set the threaded portion of the insert using a socket that spanned the threaded portion and gave it a few good hits with a heavy hammer. At first glance, it seemed that this did the trick and really set the insert in the bottom of the leg very well… Turned out that wasn’t enough and I had a wheel come out while moving along a flat, clean garage floor…

Pulled them all out, ground me a clean edge around the bottom of the leg and welded all the inserts in. No more worries.

I do think this is a real issue some are having… not sure what to blame but, it’s for real…

Never did think of measuring the disk inside the leg to see if there are any oddballs…Sry…

Thanks for chiming in- we’re going to inspect all of the caster inserts and make sure that we arent sending out defective ones from here forward.

I have 2 Castor’s that keep falling off. Seriously disappointed.

There is a community page on facebook that helps with the table, and is was one of my post about having the caster falling off while moving the table. (mine casters also fell off letting some water in the control box luckily nothing was damaged) Most of us agreed on welding the casters on the table.

same thing here only didnt have water in table yet this happening to lots of people we need to give a low report on system i bought the mac3 program months ago and and still havent been able to up load the program yet thimking of askimg for money back we get up to 500 lines anyway