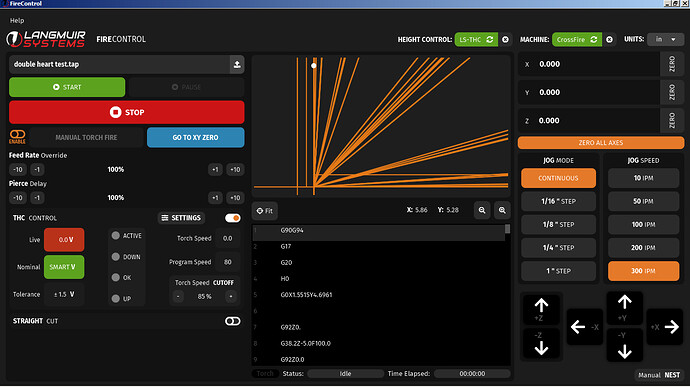

Really trying to get this running. when i load the .tap file from sheetcam it loads in firecontrol and you can see the image for a split second. In my case trying to cut a heart for my wife. So you see the heart then immediately it turns to lines every where like photo attached. And then firecontrol crashes

Hi @dj_elite sorry to hear about that! Can you please your g-code file attached to Support@langmuirsystems.com so we can take a look? Thanks!

I just emailed the .tap file

What version of Windows and which computer are you using?

windows 7 home premium x64 bit toshiba satellite L505. Ive tried a bunch of different things it keeps doing the same thing. I even reinstalled firecontrol

Do you know how much RAM it has?

4gb i just upgraded it from 3gb

If you try generating a smaller program such as using straight cut mode, are you seeing the same error?

Our first reaction is that the visualizer is crashing FireControl. We’ve tested FireControl on windows 7 computers before without issue but it’s possible with a lower performance system that it could have issue.

The good news is that we’ve been working on the first update to FireControl which includes a revamping of the visualizer to drastically decrease the processing demand of the visualizer which we hope will solve the issue that you’re seeing. The bad news is that we can’t get you an installer until Monday morning to run it…

Do you know the processor speed?

2.2ghz processor speed

I have a newer laptop for my design computer. Im going to install fire control on it now and see if that works. A fix would still be nice since Id rather run a dedicated PC for the table

That would be great! Please let us know the results.

Newer PC worked windows 10 x64 bit!

First cut. Minimal dross. Is the razorweld supposed to shoot air out for about 30 seconds after cutting?

Good job. Mine blows air after the last cut for awhile. I was told it was to cool the tip.

Looks great. I just posted a potential breakin program in the other thread. I’d be interested in whether it works. It does 2 diagonals and an outline of the max dimensions - 48.5x33.3 and has THC commands for initial pierce and cut heights. Does all of that 5 times so it should exercise the extremes of the x & y axis and at least see if normal THC movements will work. If something is going to slip I would think it’ll happen running this - it runs the “cuts” at 150ipm and the fast path should be 200ipm. That should shake it up enough to jar loose any setscrews that aren’t quite tight enough.