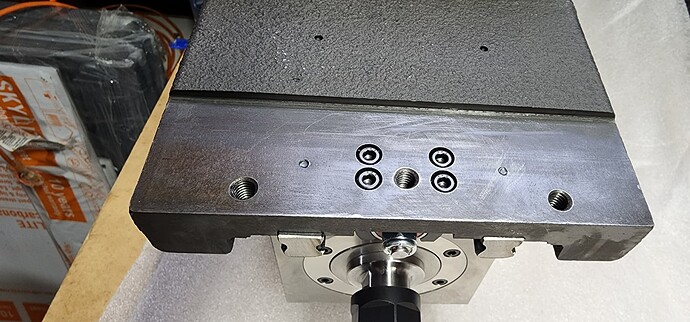

I’ve pushed just about as hard as possible to try and seat the upper bearings against the carriage, ive even used clamps all over it while pushing and with the bottom screws undone to prevent any cantilever effect, to no avail. I can even slide a .001 shim in between the carriage and the bearings on top, but According to the calculator i need 4 shims each on the bottom. It seems like the carriage mounting surface is perhaps greater than 90* because i can get the top reference faces tight with no light visible, but then the front reference surface tapers away from the carriage. Anyone have any ideas? Langmuir?

Can you disassemble and provide photos of the contact areas on the carriage? Did you take a stone to the surfaces to ensure there are no burrs? Use a square on the surfaces to see if they’re 90 degrees? Ensure no burrs on the linear bearing surfaces? Are you able to move the bearings side to side by hand even when applying pressure against them?

There is a radius in the corners and i dont have a square with a notch to accomodate that, but it does actually seem to be pretty square (to my eyes, I cant see very precisely though). I’ve meticulously stoned all mating surfaces, I did discover a burr on the bearing in between the reference surfaces that I thought could be interferring with that radius, but removing it did nothing except let light through in the corner about the mating surface, still a large gap below. I did put an indicator on, and the bottom bearings both have less that .0015" variation from one side to the other, but the top bearings both had around .005-.006.

Both bearings can move freely when i push against them.

I tested mine, I don’t have the nearly .020" !!! That you do, but they do have around .006". Have you contacted langmuir?

Thats only about .011". I have and allegedly am getting sent a new one

Oh I see, it went negative, I was thinking your dial had gone in the positive direction, nearly 20 thou.

How did you discover that they were bad? Did you try and fail to mount the carriage like me? Or did you sweep them before mounting?

I previously had a bad y axis rail with the exact same issue and could see visibly the taper on this bearing so I swept it to find this

Ah I see, well hopefully you can get your machine running soon, I know you got yours quite a while ago from your first post. I opened a support ticket and Jake said he thinks he has the answer, just waiting for him to talk to the team. Hopefully its a quick fix, I don’t know if my little heart can take another week wait lol.