Eww, no, haven’t seen that guy. I’ll run through it now. Thanks!

I see @langmuir-aksel replied to your ticket a few minutes ago - if you follow along with the flowchart, be sure to let him know the results!

After going back and forth a bit with Aksel, I found another USB cable to test with, but it was the same result. I then grabbed my wife’s laptop and installed FireControl on it, but also had the same result. He acknowledged that the wiring from the CNC port wouldn’t have voltage unless the machine was running / making cuts, but that wiring / voltage wouldn’t have an impact on my ability to enable and configure the THC settings in FireControl. It’s looking more and more like the module itself to me, but I’m waiting for his thoughts.

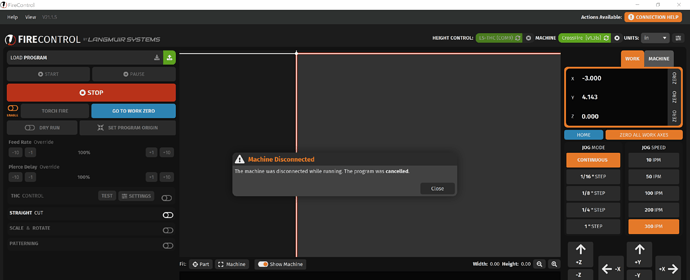

In the end they’re going to send me another module, but since I was itching to try out my machine I loaded up a .cn file to try to cut some 1/4" plate and it made it to the first hole, cut it and then the programming sequence 'crashed saying that the machine was disconnected:

I should still be able to use the machine, right?

I would try again but I would also make @langmuir-aksel aware of that error especially if it continues. That’s a potentially different issue than the THC module. Is the module still installed on the main board? I think I would remove it if you keep seeing this error.

Hey Scott,

Thanks for always being so quick to respond. I appreciate you! So since I wanted to still test out my brand-new CNC, I figured ok, I’ll just remove the module, unplug the IHS wires from inside, and then during the Post operation, uncheck the IHS and THC boxes in Fusion360 to remove that stuff from the G-Code. I figured at that point it should be just like a new machine without a THC, but when I did that, I got alarms in FireControl and nothing worked, so I re-installed the THC module and plugged the wires back in for the IHS and the alarms went away. I figured ok, I’ll just keep it installed, but keep the boxes in the Post processing unchecked so it doesn’t try to use the height control. At that point the best that I could get was the single hole cut out and the 'Machine Disconnected" error seen above. I tried probably 4 times. I can just say that the same hole his thoroughly cut out at this point, since that’s all that it does. ![]() Good call and replying back to Aksel to keep him in the loop.

Good call and replying back to Aksel to keep him in the loop.

Thanks again!

IHS is a completely separate system from the THC. You can leave the IHS hooked up and enabled and just toggle off the THC.

If you try to run a program that has IHS commands, without the IHS hooked up, you will get errors as you already know. The software is looking for input from the IHS switch, which is normally closed. If you unplug it, it becomes an open circuit.

OK, doing a bit more testing on some cheaper / thinner metal. I’m trying to cut the six-point ninja star that’s on Fireshare. This time I left the IHS cable plugged in, completely removed the THC module, checked the IHS box in the post configuration in Fusion 360 and I didn’t get the machine disconnected error, however it also didn’t fire the torch, it just went around as if it was doing a dry run or some reason. Oh well, i’ll keep playing with it.

(Update 3 mins later) - I just moved the torch off of the material, moved the Z-axis up and tried to manually fire the torch, which has always worked, and now it won’t fire. I guess I should put the THC module back in? This is crazy. Thanks!

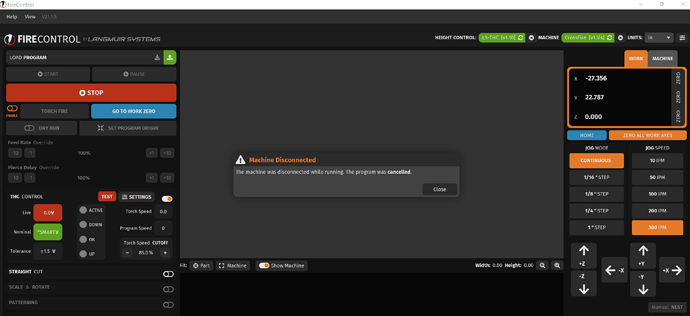

(Update 15 mins later) - I just put the THC module back in (but have the cable unplugged), and now the torch fires again, however it goes back to having the “Machine Disconnected” after cutting the initial hole. I try to click the X next to the THC, so it shows disconnected, but it’s like as soon as the torch fires, it tries to automatically re-connect and I think that’s when it fails.

(Update 45 mins later) - At this point, I think I’m just wasting time and metal. I can’t even get it to do a 6" straight cut without getting the ‘Machine Disconnected’ error.

As soon as the new THC module was installed that immediatley fixed the issue and I could see the firmware version in FireControl. Won’t actually be able to do any test cuts until next weekend, but so far it looks promising.

This is so frustrating. Just got back from a business trip to finally verify if everything is actually good. Even though the THC is now recognized after getting the new module, I still can’t cut anything. I’m still having the “Machine Disconnected Error”. See image below. I’m just trying to cut out a test ninja star that I got from Fire Share. Anyone have any ideas?

What is happening when it disconnects? Meaning what is the machine doing? Is the torch firing at the time or is it when if first pierces? As much detail as you can provide is really helpful.

Now that the machine is connecting correctly let’s start over with basic troubleshooting.

Are you using a laptop or desktop computer? Are they plugged into the 120v power source while cutting?

Confirm you’re using a Primeweld Cut60 and whether it’s supplying raw voltage or divided voltage to the VIM.

Confirm the work clamp is on the material not a slat or other part of the table.

Hi Scott,

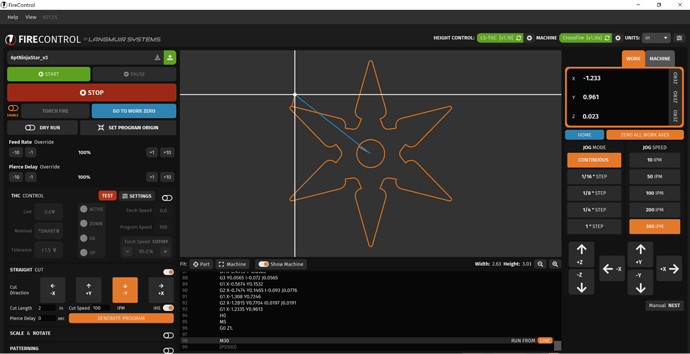

So, what I found is that if I disabled the THC, by just toggling that setting off, I could cut this guy out (ninja star that I found on FireShare):

But before that I couldn’t get the torch to fire for some reason, but if I manually pulled the trigger, it would fire just fine. Previously it fired just fine when enabling “Torch Fire”, so I just verified connectivity with a meter from the pins coming out of my PrimeWeld Cut 60, all the way to the barrel connector that plugs into the motherboard, so that was good. I only started looking at that because, when I chose the “TEST” option for the THC, I noticed it wouldn’t fire and so I kept trying it and I could hear so sort of relay on the motherboard click, so it was trying to do something, so it appeared to be something between the board and the barrel connector, so I just reseated the connector into the port yet again, and then started wiggling the barrel connector and shockingly, it then fired - so I’m not sure what that was about. Anyhow, there was some progress.

I then attempted the cut that I initially mentioned above, with the THC control disabled and it worked. I was pretty happy. I then changed nothing, but then attempted another cut with the THC enabled this time, and then it worked.

I then just tried to cut some straight lines, but got and errors and one attempt pretty much fused the torch head to the metal, so I had to manually power the machine off, and then swap out consumables - that one was likely due to the pierce delay and was probably my fault.

After that, it seems to be running a bit better, but in cutting out this one DXF for this 2x72 grinder that I’m trying to build it must have failed 12 times during the cut, but at least it let me start from where it failed so I just keep resetting and re-attempting and eventually I got through the cut. I wouldn’t call it reliable just yet, but at least its cutting. Still need to do more testing.

Cheers!

So it just fired when wiggling the connector? Was a program running at the time? Take a look at the questions I asked before and let us know what the status of those are.

Hi Scott,

Before I got the new THC, and when I tried to use the CNC without the THC, it would also get Machine Disconnected - first posted a pic 17 days ago; in that scenario the torch would be firing. It would actually cut the circle in the ninja star and then say machine disconnected. After I got the new THC, the torch wouldn’t fire, it would just say machine disconnected, until I started re-checking everything / wiggling wires etc.

I’m using a laptop on a separate table a couple of feet away from the CNC. The plasma cutter itself is on a cart between where I have the laptop and the water table. I’ve tried it both plugged in and unplugged after seeing others having better luck with it not being plugged in. For me, it doesn’t appear to make a difference.

In all cases (thus far), I’ve made sure that I have the ground clamp directly on the piece itself.

As far as my Cut 60, I set it up to use divided voltage from pins 4/6.

Regarding the wiggling that I was doing, it was with the application open, when running through the prompts for the THC test. One of the prompts wants you to click a button when it’s firing - forgot exactly what it says, something like Arc On or something - that’s when I was doing the wiggling, since it was supposed to be on.

I’m about to go out to the garage to do some more testing, so we’ll see what happens. Langmuir sent me two ferrite chokes and a USB isolator, and they just made it in today. I’m gonna put them on the USB cable and put the isolator in-line between the laptop and CNC. I’ll re-post after some testing.

Thanks again!

OK great! I’m wondering about the quality of the connections for the torch on/off connector that is part of the control box? I have seen people talk about having bad solder joints on those types of connections.

They appear ok to me.

So far things have been working ok as far as thing firing and making cuts - but I just tried to cut some 3/8" plate and I was having a helluva time. I saw a whole separate thread on the topic though specifically for 3/8" plate and the PrimeWeld Cut 60. Tried about 5 different configurations and swapped consumables out twice. I think it comes down to just needing to slow down the IPM. The odd part is that it would work fine with one configuration, but as soon as I cut a larger piece out it would eventually stop cutting all the way through and then just make a mess on top of the metal. I had the air pressure at 70psi and its coming from a 60 gallon tank, but maybe I need to get a larger diameter hose or something. Not sure, but I’ll eventually get it all figured out. Gonna go back and read through that one thread again as well.

Hey @TomNorton

Following along with this old post, seems like my problem is right where you started. I tried most of the fixes you have gone through. When you found that THC troubleshooting guide was that of any help? seems like none of that matters at all if the connectivity to the THC module is off. I know my THC voltage is not reading right but haven’t had the shop time to run through diagnosing where the error occurs. I had been cutting with the THC toggled off, but after a lunch break the THC version was no longer visible. This left me with the torch firing properly but no movement after. Need to try and convince @langmuirsystems support to send a replacement module

Hey @metalcraftnw

No problem, we are happy to help out and get to the root cause of this issue. Our phones are open M-F 9-5CST 833-526-4797. Fully transparent, I am light on techs this and next week, but we will be able to help. Thanks and reach out if we can help with anything else!

thanks for the reply zack!

your support team has been great so far. This is my first post and first time reaching out to you all about a problem, talked with Cameron originally and sent him some email updates. Seems today I need to look into another piece of equipment, waiting on a call back from them. I will be calling soon after that though