my first attempt that held me over was a air hose in a 5 gallon bucket of water then a bead cell dyrer. effective but not a replacement for a good drying system.

Probably not the tubing. More likely the fittings. But I’m glad you checked! ![]()

It would work well… IF …the air entering it is below a certain amount of pressure, temperature and water.

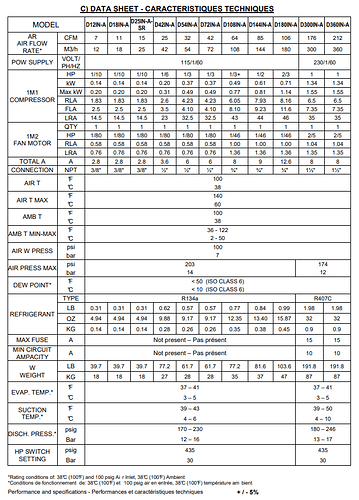

Looking at the spec sheet we see the D12IN listed in the further left column.

You will want a desiccant cell after this and then some kind of particle filer before your Plasma.

Biggest thing is, anywhere you have a vertical pipe, place a drip leg with a valve on the bottom. Even with refrigerated air dryers you still get some moisture left in the system. Do several vertical pipes side by side with drip legs. Drip legs I mean a small leg sticking down with a valve. If you do about 4 to 5 vertical, by the 4th or 5th leg, you have little to no moisture left. 4" to 6" drip leg and 8’ vertical legs, the taller the better.

I seen it done with PVC, metal, copper, and stainless. Seems to not be much difference. PVC just need to keep pressure lower, I run 80PSI on PVC. Although, I know a guy that had a shop and ran 275psi on PVC for many years.

For low volume air, 3/4" works good. Higher volume 1" to 1 1/4" pipe. You can also use a reducer and 1/4" ball valve to reduce cost. The larger diameter the better.

I have also for work placed immediately after compressor, an old 20lbs propane cylinder with a drain welded in the bottom. I Tee’d the 20lbs cylinder inline after the compressor for a surge tank, but discovered it filled with water in about a week. I was amazed of the amount of water captured in the cylinder. We do have a dryer on the system already, but the accidental water trap pulls out most of the water. I’ll try to get a photo next time I’m there.