I was going to go the max air line from Amazon but then I started to do the math on the fittings and each 90 is about 30 bucks. That’s expensive. So I went the 3/4 copper line. My question is does it matter if the line is outside, against my wall on the outside of the garage. Since my compressor is located outside in a shed that’s against my garage wall. I really don’t want to add it in between the power outlet and the switch.

This could work if its not too cold. If it get below 0 C (32 F) the water vapour will begin to freeze. ( even refrigerated air dryer only lowers the temperature to between 2-4 Deg C) Heck if the air in the air is at the right humidly, pressure and its cold enough outside to cause deposition of the water vapour ,skipping condensing all together.

The “job” of the after (inter) cooling is only to bring the air temperature down to ambient conditions (65-80 F) but cooler the better unless its freezing.

The concern is freezing in the air lines.

I do live in California so in the winter it does get in the low 30s and sometimes in the high 20s, but it warms back up once the sun comes out. I wanted the lines outside so that I can keep the drain water off my walls inside. As you can see I slapped some A60 14 gage on my walls.

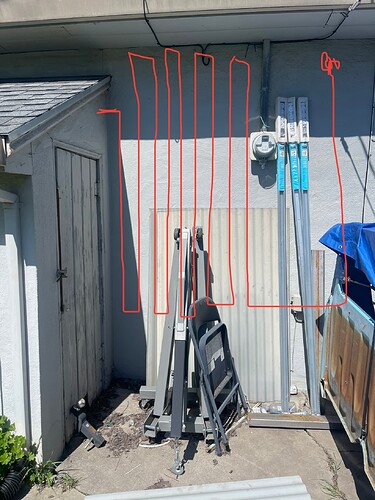

I know this is merely a quick graphic to show the route of the lines but hopefully you will have something on the down legs to deal with water condensation. The heat of outside may hamper you cooling efforts in the summer. Of course, you might have minimal moisture in you air in the heat of the summer.

I had minimal wall space. This is what I did with PEX tubing:

Regarding the pictures:

Pictures one and two: The routing of the pipe is fine.

Picture three: It’s a good idea to plumb to an area where you can easily distribute to your refrigerated air dryer and desiccant for service and maintenance.

Picture four: Here are some suggestions to improve the setup:

Limit the last bend before the pipe enters the wall and try to come straight across to that point instead.

Bring the entry point further down the wall so it enters closer to the corner behind and above the crossfire.

Install a bypass for the heat exchanger during the hot summer months, as direct sunlight might make it too hot to be effective.

Install driptees and drains at the bottom of the loop (on the downstream side of U) and every major vertical drop too.

Also, I recommend adding a regulator before the air distribution system, set below the tank pressure but still higher than your ultimate operating pressure. Additionally, adding a flexible connection between the tank and the solid pipe mounted to the building would be helpful.

Well that is certainly unique! Akin to some nuclear reactor cooling towers I’ve seen. I especially like the Fan Hangers and the Christmas lights on your water tank.

That is the kindest thing you could have said! Notice that I did not encourage anyone to follow in my footsteps.

Ok here is my 2 cents

Having your compressor in a unconditioned space is not ideal. To hot in summer and to cold in winter.

The pipe layout in the last pic may not cool the air much if its hot out and the sun is beating on it.

Thanks guys I appreciate all the input I can get. Since is does get really hot in the summer here I’ll probably move the lines inside the garage. So I’ll go back to the drawing board with the input I got and then post later. Unless someone draws a ideal air line run for me lol

Should I move my compressor I to the garage? I wanted to avoid this because it’s really loud. Or would it be okay if I was to insulate my pump room where it’s located at now? I already have the power ran to that room.

The key thing is to have an air exchange with your workshop so you’re not sucking outside damp air. You need ducting to supply air from your workshop to a sealed room with your compressor. If you have that, the compressor can be anywhere.

Could you put it(cooler) in the shed with the compressor? Seems like having it in the direct sunlight will be a challenge to get the air cooled? If it were on a wall that was shaded in the summer it would be better but probably not an option.

Try it this summer and see how hot it gets in there. That style compressor runs hot and as you said pretty noisy.

I often wonder how effective it would be to have the cooling pipes in a water filled tub. It would not have to be elaborate. Just have a stock tank float valve refill as the water evaporates. The fresh water is likely in the 60’s or 70 degree range. The transfer of heat from the pipes would be very efficient compared to air exchange.

The down side of that thought is that most of the condensation would be on the “down-side” of the pipes in the water. Unless you went a tad more elaborate and have the water be a collar around the pipes allowing them to extend through the bottom of the water vessel. Then you would have access to grab some of that condensation off.

Actually this is in the planning stage for my setup.

I’m going to install something like this in a 15 gallon stainless pot I have lying around. It’s stainless steel and called a HERMS coil. They’re used in beer brewing. With the upper and lower bulkhead fittings it’ll be a breeze to plumb in a water separator off the bottom. Fill the pot with water and maybe some ice and bada-bing bada-boom poor man’s refrigerated air dryer.

Double check the pressure rating. I’ve had some powerful beers, but none of them operating at 175 PSI…

Good call. I was shocked to see they were only rated to 50 psi… That stainless must be fairly thin.

Oh well back to my original plan of fabbing it out of copper tubing.

Well that just means you need 3 of 'em!!! ![]()