I have a breakaway torch holder on my Pro with a switch to stop the machine in case the torch gets jammed and falls off. My question is I wired the grounds from the 36v power supply for the drives through a DPDT relay to cut power like a e-stop and that worked perfect, now the only thing left to do is cut the power to the torch fire relay. Now should I cut it directly at the torch fire relay or could I just run one of the 2 torch on wires (purple or orange) through the other pole of my relay. Will that work? Thanks

Looks good, you have a mighty clean machine there.

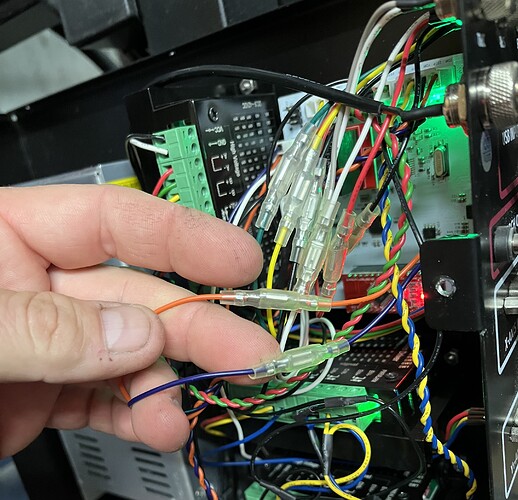

using the orange/purple wires should work. i added an e-stop to mine where when pressed just turns off the torch. no real need to stop the whole machine since we can go back to the last line is was cutting and start from there.

the e-stop is between the 2 orange wires.

very nice set-up and a clean machine…

I have been cuttin for over 4 years and have had maybe 1 or 2 times when a tip-up caused me an issue.

and even less now that I swutched to pinted slats.

All this work and set up with auto off and break away torch seems like a lot of work for something that really does not happen…also…seems like more to maintaina and possibly break…

just my thoughts on this…

When the torch costs close to 1k I’m not taking any chances, plus it’s just a relay and a micro switch and that’s it. Nothing to maintain.

Yeah… I have had my torch catch a 2’ square chunk of 1/4 plate and pushed it a few inches before I got to the stop button in Fire Control. No harm to the torch The stepper motors will stall before the torch takes damage.