Keep in mind, this is what has been working for me. Others have their own methods:

The limit switch is still really new and I still get errors telling me I am outside of the parameters. If you get that warning simply touch the “Home” button in FireControl and it will then warn you that it is going to home the machine. It will home in the left back corner and stop. At that point, you are then free to move the torch with the x and y buttons on FireControl. You should probably back the speed down from 300 ipm to 100 ipm until you get more familiar with it.

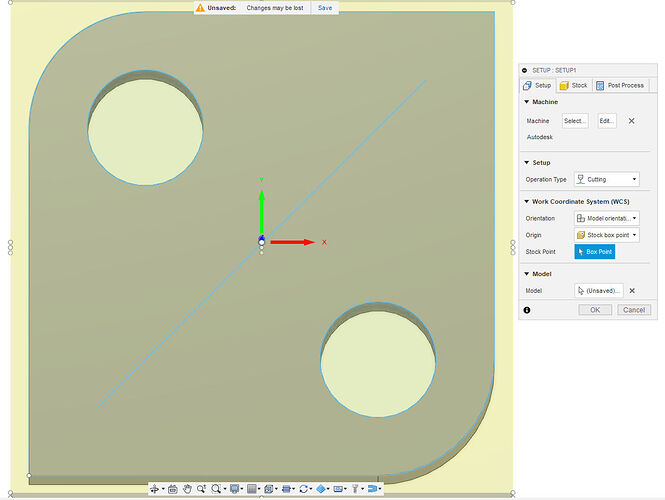

Stop the torch approximately where you expect your project to burn. The next steps will tell the machine you are meant to be in the area: Click on “Set Program Origin”. You can pick one of the corners or the center of the project. You will pick what fits with where you suspect your torch is right now and will be located when it starts the program. Before you do anything else, click “zero all axes”. These steps can be done in the opposite order: zero axes and the program origin if you like.

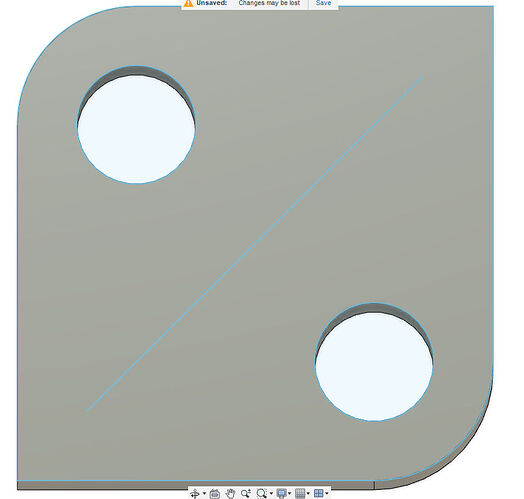

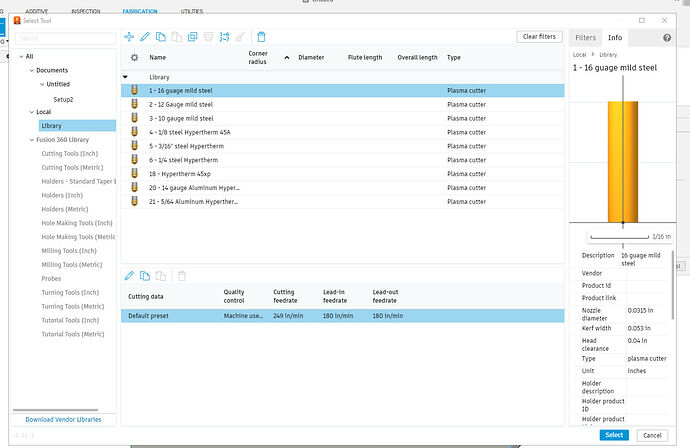

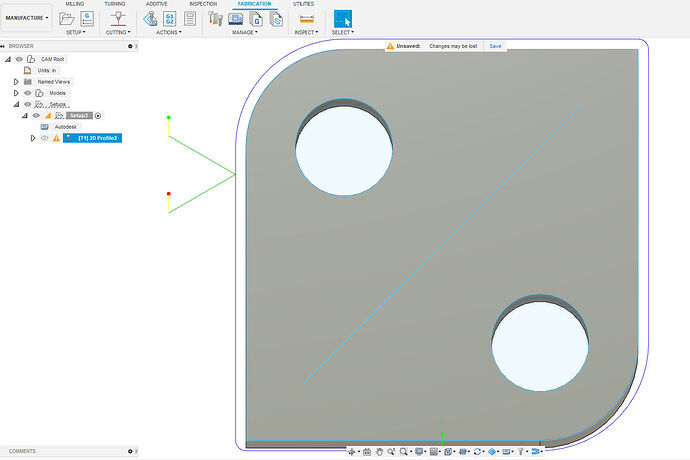

The torch start position is not where the torch starts its first burn. It is just how you tell the program where you expect that corner of the project to be on the metal. The “manufacture” space in Fusion 360 would show you where the first burn happens if you ran the animated sequence. No matter, you will also be able to see on FireControl graphic. I still have trouble reading some of those graphics. (I have lots of floaters in my vision so it is difficult for me to see fine lines on that 12 inch wide screen.)

So you have your air connected to the plasma cutter, the work lead is attached to the metal, plasma cutter is turned on. You have your shade glasses.

The best thing that you can do, to ease your stress, is to click, “Go to Work Zero” (not necessary if you are already at x= 0.0, y= 0.0), “DRY RUN” and then “START.” That will run the entire program without actually firing the torch. If that goes fine then you know you are over metal and within the boundaries. To start the sequence for real, turn off the “Dry Run”, click on “Go To Work Zero”, “Start”.

I was very nervous with my first firing. It is louder than I expected and be prepared for the water to be spraying everywhere when the burn is done. The torch stops and the air continues blowing for about 20 seconds to cool down the torch, so if the air is not restricted by any metal and it is near an edge of the table, you will have lots of water on the floor.

Edit: To limit the water splashing at the end you can do one of two things: 1. slide a scrap piece of metal between the torch and the water tray; or 2. Move the torch with torch control on FireControl. DO NOT turn off the plasma cutter or the air. The cool down cycle is to protect the equipment.

As I always say: “If you don’t make some mistakes, you are not learning anything.” I have never said that but that is how many of us have learned a lot of things. I am sure I missed something but when it happens I will say “Oh yes, that needs to be done too.”

I think you can disregard that instruction. That was one of the topics on this forum. G-code has already decided where it is going to start. You simply need to tell FireControl where the image is going to be on the metal. The rest is all magic and carved in digital stone.