I picked up my Crossfire Pro used and am a bit of a noob. Wanting more juice for thicker cuts, I purchased the BTC800XP recently from Amazon for $617+tax. I read this post while I was trying to make the decision to pull the trigger. Being a bit of a noob, I didn’t understand what this 3 second delay really meant. For the benefit of anyone else considering the Bestarc, I’ll try to put the 3 second delay thing in terms I might have better understood before my purchase.

For example, my wife has me cutting some 24x24 monogram signs for some last-minute family Christmas gifts. As you can imagine, the cut path for the torch involves a lot of pierce/cut sequences. The first pierce/cut works just fine. However, when the torch moves to the 2nd pierce/cut in the pattern, the torch fails to fire and an error pops-up on FireControl software. Granted, you have the option to retry the failed cut and that will work. But, when the torch moves onto the 3rd pierce/cut once again it fails….and will keep failing on every pierce cut after that in the pattern.

This is all due to the 3-second post flow requirement the Bestarc has baked-in internally. Tobias, thank you for your original post and the leg work on the issue. Just wish I could have connected the dots sooner

Some solutions…

-

Modifying the FireControl-v1.6.cps file with notepad (it’s just a text file) as Tobias pointed out above. This is pretty fancy. When you load the file with those changes into Fusion 360, you will see the option to add your delay.

-

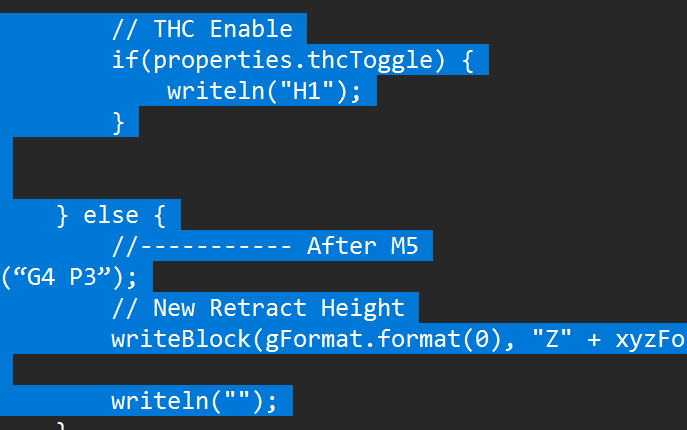

Modify the FireControl-v1.6.cps by simply finding this line in the file… //————–After M5

and then insert this line below that one… writeln(“G4 P3”);

When you load the modified file in Fusion 360, you won’t see the option, it will simply add the 3 second dwell for every cut.

-

Or you could leave those files alone and manually add G4 P3 in your gcode files. Like I mentioned before they are just text file that you can open with notepad. Simply look for the lines that are M5 and add G4 P3 on the next line.

-

Another option is a writing a little console application. Again, since the gcode is a text file a computer program can easily inject the G4 P3 lines into the existing file. The one I wrote was in c#, but you can use just about any programming language.

Unfortunately, these solutions are really more like a work-a-rounds. When I ran my first file with the extra 3 second dwell instructions I was feeling like I made some headway. I thought, this may be ok after all. Then, I decided oh, I’d like to set the post flow dial on the Bestarc to 15 seconds. Bad move, this caused the next pierce/cut to fail again. I dialed it back to 5 seconds and things seemed to keep working. I would wait until I was on the final cut and I would turn up the dial to 15, which worked after the final cut. Now, all I had to do is remember to dial it back to 5 before cutting my next monogram. Hmmm….all I have to do is remember, this, that, and then this…grrr.

By this time, I had spent a full day chasing this issue and my patience had all but run out. So, the Bestarc was delivered on Friday, spent all day Saturday chasing, by Sunday evening it was packed back up, and Monday morning it was at UPS on its’ way back to the Amazon.

I really think if Bestarc can get that one thing resolved, they’d have a nice budget machine contender. I just couldn’t live with the on-going hassle.

Well, while it was a pain going through all of that, it was a great learning experience. It also made me feel much better about my Monday purchase….82i on the way.

I guess, if I would have started with the 82i, I wouldn’t have had all the frustration the Bestarc gave me. Knowing me, I would have spent time wondering if I went overboard and invested too much for my simple shade tree cutting needs. A guilt free 82i decision is a good thing. Guess the tuition paid on this schooling was worth it.

btw, great forum!

p.s.

Tobias, in all my googling I thought for sure I saw a post somewhere that this 3 second thing could be overcome on a manual torch by simply pulling the trigger twice? Hindsight and all, I wonder if someone that still has a Bestarc were to modify their cut file to not include the 3 second dwell, but instead add an extra H1? Wonder if this would mimic pulling the trigger twice?

so like…

G0 Z0.118 (Pierce Height)

M3

G4 P0.5

G1 Z0.059 F3.937 (Cut Height)

H1

H1

G1 ….

eh, could be a pipe dream, guess I need to move on

![]()