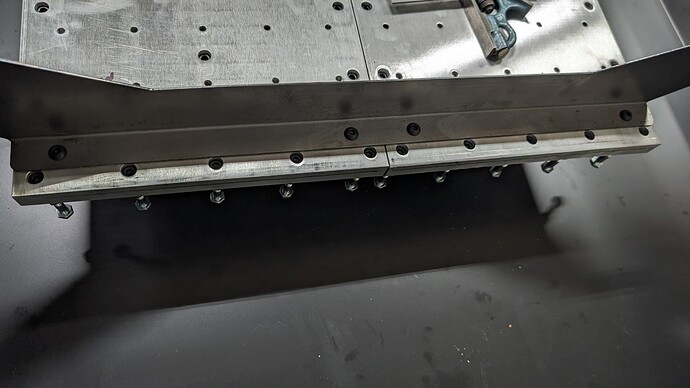

How base plate was received. Front and back edges not even, different surface finishes. Know the top gets cut but not sure if the machine extents can reach outer edge perimeter to clean this up. Considering half the plate is submerged in concrete…how well and close can you get to be able to clean it up. It’s not a functional thing but it is a very visible thing that looks like crap. The one thing the machine is capable of looks like it’s not very capable of… Can already hear the comments from visitors that see it.

Langmuir has already acknowledged that some plate may not line up perfect. Since these plates are extrusion so dimensions can vary a bit. Since this is a cosmetic issue that in know way effect the functionality or accuracy of the machine it is really up to the builder if you want to fix the issue.

For those who the aesthetic look is important it’s simple to just grind down the higher plates edge tell you have a smooth transition before installation. That is what I did!

Yea… saw/heard that as well but wasn’t expecting this level of uneven/ surface finish issues. Can’t even use the machine to clean it up since everything is complete before final assembly. Can understand if all the errors are to the back but the first thing and prominent thing you see when you open the doors and look in is the base plate and that front edge. Will definitely have to address it prior to pouring concrete.

Does the other edge line up better? Could just rotate 180 if it does?

Alignment a little better (still 3/16-1/8 out) but surface finish is not. Neither are what I would want to see in the front. Back don’t care but I like great coming off the machine as much as the machine looking great. I take care of my tools…sure it’s just an anal thing but I know it would bother me every time I open the doors.

Just grind the front edge smooth, it gets set in concrete and epoxy. After you put the machine together and you finish the surface you won’t notice it.

Aluminum plate… don’t see myself grinding 1/8" of aluminum across just under two foot. I’ll figure something out.

Yup, fit and finish here is crap. I get them not machining the top and bottom surfaces since that’ll happen after installation, but it would be nice if they were cut to the same length and had the holes at the right place and there was no possibility of installing one plate backwards.

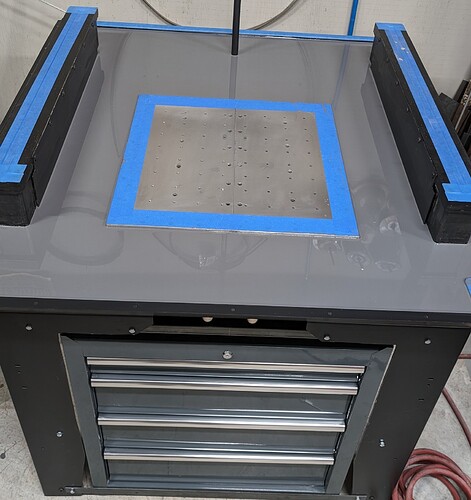

I thought about taking mine to a friend’s machine shop and truing them up, but I just installed them as is and put the staggered joint at the far end of the machine. I haven’t thought about it for the 11 months that my machine has been in operation – I’m guessing you won’t either.

Stand corrected… I took a flap disc to it and it cleaned up pretty good and easy. Little sanding and it’s good enough. Little more than a brushed look but at least it looks straight. Anyone get any closer and I’ll run them out of the shop…lol

I think once you get the machine built and running your will be to busy to notice. Than it will be to busy and dirty for anyone to even notice!