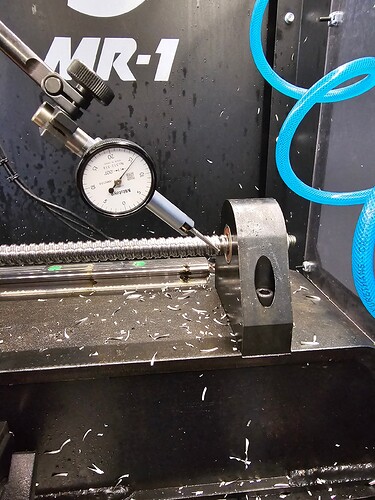

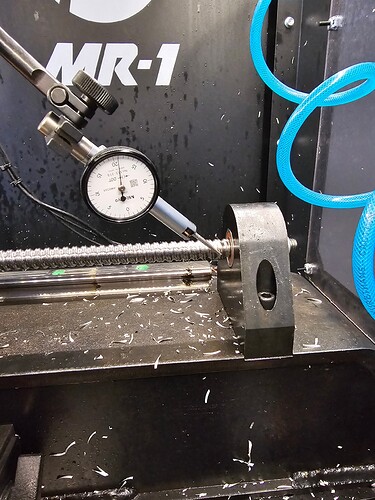

Just wondering if anyone else has a similar issue or if its normal before I email Langmuir. I noticed today my X axis and my Y axis bearing carriers have roughly .005 of play almost like the bores were over machined or missed tolerance. also my x axis sound like a burnout when running at 50ipm every other speed sound flawless is this just a resonance issue ?

I also Took this measurement from both sides of the bearing block and it has no change

I assume you’re measuring radial play? If so, radial play has no bearing on rigidity or accuracy in the system and won’t affect proper operation. Its likely intentional actually.

Axial play (thrust forces) is whats critical on ball screws.

As for the strange X stepper sound, I’d have to see/hear a video to be of any help there. I don’t have any resonance in my machine unless under cutting loads.

Yes im measuring radial play. And thats why i consulted here first lol. I set the lash to langmuirs specs and it seems good so i wont worry about it then. Wouldn’t a tapered roller bearing be better for this application though ? Just seems that you could tighten the nut down all the way and not really worry ?

They are tapered bearings. They are color coded to make sure they get put in correctly. You tighten the nut down too much and its adds significant force to the bearings and will cause binding and premature failure. The point of adjusting backlash, is to get them tight enough to remove play, but not too tight to cause binding or ruin them.

Never noticed that! You made me go check to make sure mine were installed correctly (they are ) seems like a light press fit would still be best no ?

It’s not really necessary, as the ball screws are only handling positioning axially, and so axial lash needs to be controlled. The linear bearings do most of the work. Of course, you don’t want hardly any lateral movement, but several thousandths shouldn’t cause any issues.

I have same loud noise when in 50ipm as well. Haven’t seen anything about it. Was wondering the same thing… is something wrong?? I changed drivers and wasn’t happening with the stock “smaller” ones. Cant remember if it happens in cnc mode but definitely when manually moving the machine. I have avoided using 50 and all my programs have never had 50 as part of the feed/speed process.

Mcaffey, All stepper motors make noise, and sometimes that noise/vibration will imprint on surface finishes. You might want to try lowering your amp settings on the drivers. I installed the EM542S drivers, and I was getting horrible noise and jerking on the Y axis with the amps set to the highest settings. I dropped it down two steps from the highest setting and it cleared right up. I suspect the stepper motors can’t handle the 4.2 peak amps that the EM542S driver delivers .

I put in the DM860T drivers. They seem to be fine in all axis and all speeds except for x at 50ipm. Just weird it’s quiet in all speeds/axis except the one axis and one speed.