Just bought a new everlast 82i. Was using an everlast power plasma 50. Had no issues with the 50. Now, with the 82i, the arc will start and sometimes I can get several inches of cut, but most of the time as soon as the arc starts I lose connection. No charger hooked up to the laptop, moved the plasma away from the control box, USB in to the control box is not grounding out, moved USB on laptop to other USB ports, raw voltage coming straight from the lugs inside the plasma cutter, and using CNC port for torch on and off only. Not sure why everything was working good with the 50 and now with the 82i I keep losing connection. Are there other things I should check? Took a video but I can’t get it load here. Any help would be greatly appreciated.

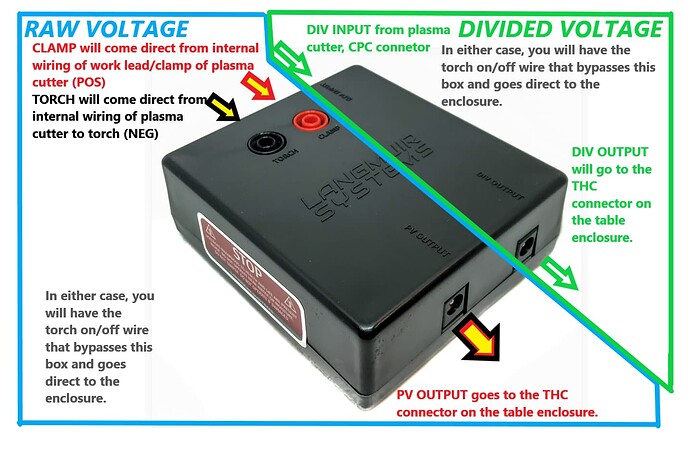

Double check your connections to the VIM box.

And make sure your air pressure is at least 85 psi to the back of the cutter. Then check the torch electrode to be sure that the electrode has movement for the ignition.

Also, I have checked to make sure the electrode moves and springs back.

I’ve checked the wiring from the plasma cutter to the box all of that is good. I have air pressure set to 75psi to the cutter and the little I’ve been able to cut before it shuts down, it hasn’t dropped below 70 psi. Other posts have said these machines like the 75 psi but when I get home today, I will set it to 85 psi and see if that works. Thank you for the info!

It is probably not the air pressure since you are seeing 70 psi when it is cutting. Is that pressure measured at a gauge on the back of the machine (near the machine) or the pressure at the compressor?

Keep in mind that 85 psi is just a suggestion to see if it makes a difference. The manual and most guides recommend the pressure you are using. The manual says not to exceed 90 psi. so 85 psi would/should be safe to try.

I’m going off the gauge at the compressor. I don’t have one right before the cutter yet. I’ll put one one and see if that is more accurate.

Set the air to the plasma cutter from compressor to 100 to 120 PSI. Set the air at the plasma cutter to 70/75 psi with air flowing from the torch. If you need help contact me.

Ok, I don’t really know what the issue was but I bought a new usb cable with booster and put that on, I put some ferrite rings on the usb cable, and upped my pressure to the cutter to 90psi and set pressure to cut at 75. I ran several small cut files and never had any issues except when I loaded one of the cut files, pierce delay was black and the torch wouldn’t fire. I manually set the delay and then the torch fired fine. Reloaded the file and pierce delay was there this time. Anyways, looks like it’s going for now. Thank you for the info! If I have any more issues, I’ll be back. Lol