If I recall correctly, pins 1 & 2? They activate an LED on the front panel to say “CNC” mode. I soldered them together in hope that it changed post air flow behavior. Sadly, it only turns the CNC mode light on. Oddly, their custom CNC interface cable does not come with those two pins connected.

Sorry a little late to this thread. Did you ever change the retaining cup on the Bestarc? I was wondering if you have the wrong one on it. It will not re-fire until post flow stops. The retaining cup must have 6 air holes in it to disperse of the air, if it only has 4 holes as in the picture it will not re-fire. Just something I have seen in the past.

I started a topic over at the fusion forum to light a fire under autodesk to add this feature

I brought it up historically but this is the link for requesting features from autodesk.

There’s no reason as a community of over 10,000 people that we shouldn’t be spamming them trying to get the features we want.

Add a pause after every cut

Center mark

Wiggle Pierce

Etc.

Squeaky wheel gets the grease.

Between all of this I’m sure we spend millions of dollars on autodesk a year.

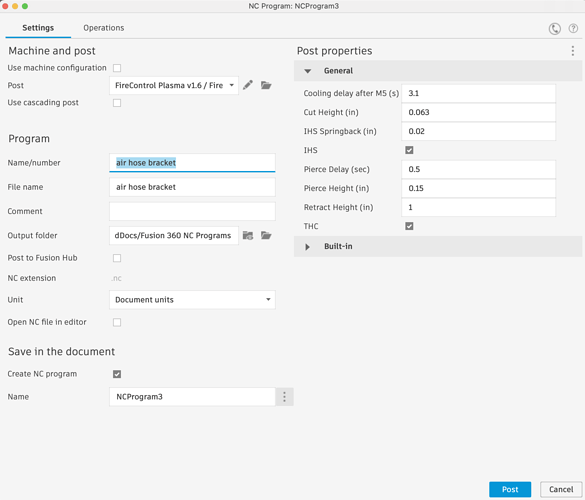

I found a way to add the delay to the post-processor file. It appears I cannot attach a .cps file. I’ll have to share another way? Here is an example of how it changes the post-processor screen. Also, I will find the link to a post where I shared how ChatGPT helped create this code.

Here is the other post. Bestarc BTC800XP and CrossFire Pro - #15 by Tobias .

Will check this today and get back to you. If this is the case, Bestarc support does not know about it either! I’ll reply by end of day.

There are a few other things that most people don’t know about the Best Arc BTC800XP. First, the IPT60 style torch is only rated at 60 amps. Second, the consumables are not for a IPT60 torch they are S45 style and only rated at 40 amps. So you have a 80 amp plasma cutter with a copy 60 amp torch and 40 amp consumables. I bet support didn’t tell you that as well.

Explains why I go through consumables with this Bestarc kit like butter on good French bread (no holding back). So, looks like I have six holes in all my existing retaining caps. I have two consumable boxes. Contents are the same, but one says it supports the 800xp ![]() . Guess marketing fixed that.

. Guess marketing fixed that.

Well at least you have a 6 hole cup. Now all you need it to get a 80 amp torch with good consumables to make it work right.

You will be better off with the Hypertherm on the table anyway.

If you like you can always PM, email or call me if you need more info on your plasma cutter, torch or consumables.

I will take you up on that offer!