If so I would like to send you some parts I make to see how they clean up before I make the investment.

This would require a aggressive media/stone able to get in to small areas.

I will pay you

Get one of the plastic vibrating tumblers from hazard fraud for like $60 and try it out.

I did try one of those a few years ago and it didn’t do much, but I never experimented with different media.

Not sure how long I ran it but quit working after awhile so I just took it back.

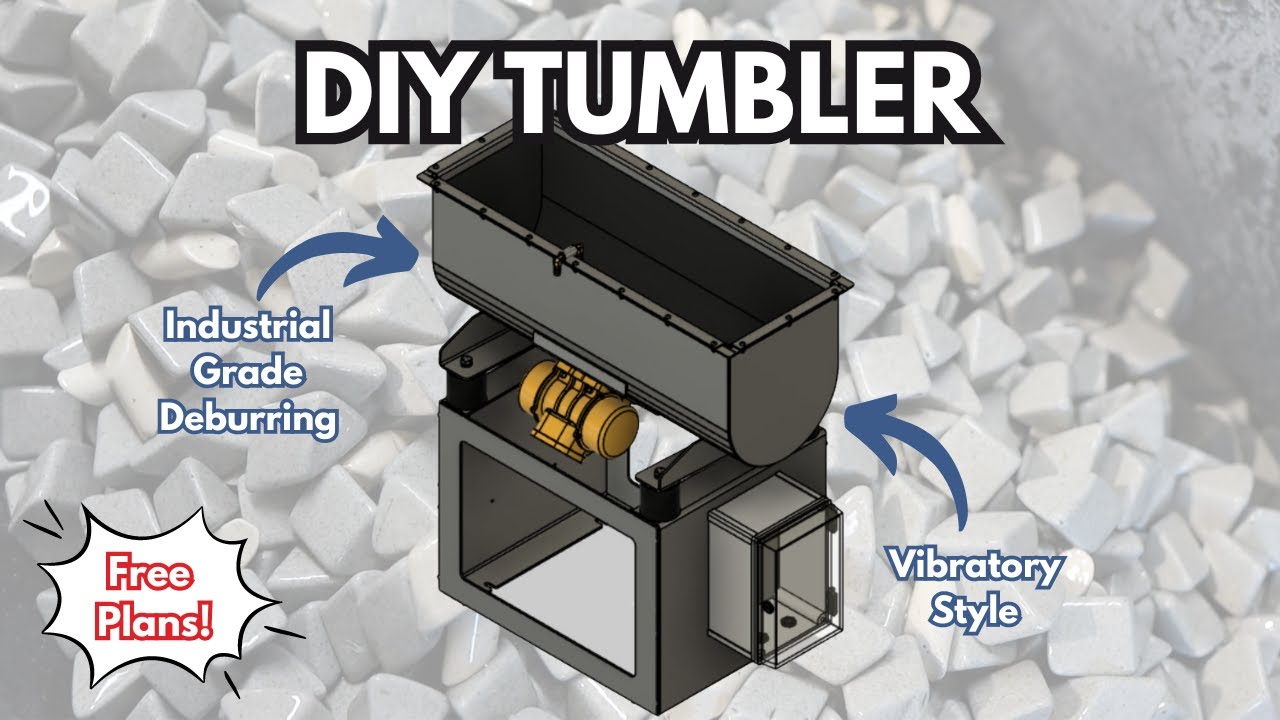

I am getting ready to order all the parts for this tumbler kit from Laser bros.

nice hardware lists from McMaster

we’ll cut and bend all the sheet metal parts inhouse .

Most tool rental stores rent concrete mixers.

Might be cheaper than shipping parts

I use one often they work great for what I do.

These parts are small so shipping will be cheap. Let me know if you get a batch you are going to do and I will vote for you to give mine a cleaning! ![]()

If I find the results are good I might build the one tin posted, looks pretty nice!

What’s the specs on the parts? Can you post a picture of them.

My concrete mixer can be aggressive if the parts are thin they could bend.

I also have my cuts dialed in to the point a little tap will knock off the majority of the slag. The mixer just allows me to do quantities. I will do batch of 500 to 1000 at a time so it is a time saver.

The company I work for has a large tumbler the the shop used when our fab shop was open they said it works nice

I use one of these, whilst not a tumbler you can get similar results depending what type media you use, assuming your not trying to polish the parts.

I’ve used one of those harbor freight tumblers quite a bit for keychains. I used their abrasive

It did very well on smoothing edges and putting a nice surface on mild steel and some stainless. The trick was not leaving it in too long. The parts would accumulate clumps of dust after a bit and it was a pain to clean them off again. Plus, the results didn’t seem too different based on adding even more time.

The keychains I was doing were about 1.5x2.5. They had a roughly 3/8 hole that had smooth edges after coming out as well.

I have one of those vibratory cleaners that I used to use for tumbling brass for reloading.

I got some of that triangular media from harbor freight to try using it for plasma cut parts. The results were not great. The parts kept finding each other and stacking up, which prevented them from being cleaned by the media.

Could use a rotary rock tumbler style system. The Thumblers Tumbler is a decent unit.

Get one of the plastic vibrating tumblers from hazard fraud for like $60 and try it out.

I use this same bowl to deburr the aluminum parts when they come of the MR-1. works great!

That’s empty right cause it sure is quiet

Looks good what’s the dim’s?

yup it is empty…I put a few things in it earlier…yup…noisey all right…

so … BIG RED…

the main cylinder is the center of a large commercial compressor that is 24" in diameter made of 3/16" steel…

I capped the ends with 3/16" plate

it is almost 30" long…

1" shaft

it rotates at around 20rpm…

it is run by a 1/4hp 1720rpm motor wish goes through a gearbox I found somewhere that allows me to reduce 13:1 ratio…then with the pully sizes it gets down to 20rpm.

there are 3 paddles inside for tumble action…

gotta a bit more work to do to “Big Red”

Curious as to how that works compared to the style Tin posted

I use a concrete mixer with parts and stone. Here are a couple vids

First TikTok - Make Your Day

Update TikTok - Make Your Day

That second video looks like it did a good job. I am curious how the harbor freight mixer holds up.

I have seen where some guys have had problems with them failing on long run times.

How long have you been using it?

Thanks for posting

Curious to see what you wanted to test a mixer on. You can provide specs and a dxf I can cut a few samples maybe and provide pictures then tumble and send the parts to you. It would be beneficial to see how much clean up is required with your cuts.

I am going to send you some of the parts, just have not had time maybe this week. is that ok?