I have cut some great files. I consider my Fusion 360 work to be getting better and better. One issue I have had since the start. If my machine is cold it will fire the torch then go out and I have to hit retry cut. It only happens when it is cold and always cuts perfect after I tell it to retry. A few weeks ago my torch quit firing all together and had to get a new MCB. I figured that my torch burn out issue on cold starts was just an early sign, but when I got my machine running again I have the original problem still. Anyone have any ideas? It cuts great, and I can cut files back to back with no issue except for the first cut on a cold machine.

guessing…tiny bit of moisture in line. If your heating shop up and letting it get cold overnight the moisture could be in the air line and once it gets moving no more issue.

I guess that is possible but the heat is running through the night. I also have a desiccant filter right on the back of the cart my cutter sits on, but that makes the most sense of anything I have thought of. Yesterday it done it after only cooling for 2 hours.

What plasma cutter do you have? A desiccant filters don’t work if the air gets hot, moisture in hot air will pass through the filter. Do you have or what do you have to get the air cool before the filter and are you draining the compressor and lines daily?

I have drain points along the line and also drain the compressor before every use. I really don’t think it is a heat issue because it only does it when it is cold. Once I run one file the rest run fine. I can run pretty much nonstop for 6 hours without issue.

Hynade Cut80 with a PTM80 machine torch. May just be a thing with the torch but thought maybe someon had had the issue and found the answer.

It may be the machine torch. I have seen some torch’s were the power wire inside was a little stiff and when first used would cause misfires. Once they warmed up they would work fine. I would recommend doing some random cuts on scrap to warm up the torch before starting to cut your projects.

That makes sense, I know it got better when I remounted it and got the torch mount off the bottom.

Just spit-balling here, but if you originally had your torch mount lower, is it a possibility that you may have deformed it ever so slightly such that when cold it restricts the plunger, but when it warms it expands enough so that the plunger can again move freely?

Either way at least it’s more annoying than debilitating.

I have wondered the same thing, as long as it is just the annoying range I will leave it. If it becomes debilitating I will try the hand torch on the other mount and if that works I will get a new machine torch.

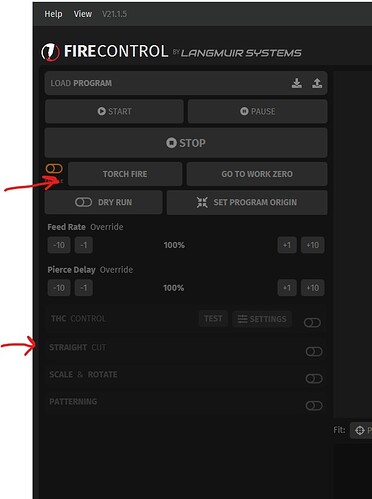

I would say fire the torch so you’re not starting to cut your design and have to reset it if always happens.

i know you can do straight lines cut off your work area of like 0.1". This might be easy option. Not sure, if you can just fire touch but you could try it.

I am going to try this before making my next cut