Yes, airflow went from head to cooler to water separator to tank. @Knick the EMAX has a killer warranty, but I will look into the reliability of the 10HP motors before dropping that kind of money on a compressor.

The extra pressure on the pump is the reason I removed mine. I have a two stage compressor rated at about 24 cfm 7.5 hp. The first pump lasted about 25 years. I had a bearing go down while I was out of town I had forgotten to turn in off

I think this thread might be heading towards at least one anecdotal conclusion: aftercooler between pump and tank has the potential to create backpressure, increased run-time, & heat buildup in excess of what exists without said intercooler, and possibly outside the planned range for which the compressor was engineered.

But I’m not gonna be the one to say it and be labelled ![]()

I don’t think pressure was a factor at all, it’s an air compressor making pressure is it’s sole purpose in life. Mounting it directly in front of the compressor so the pulley fan is moving air through the heat sinks on the head after it has traveled through the heat dissipating fins of a 300 degree cooler on the other hand “may” be responsible for a 30ish degree increase in head temps that “may” be responsible for a blown head gasket on a 17 year old heavily used air compressor. It could also just be the moons of Sagitarius are misaligned with the dawn of Aquarius…

A after cooler between the pump and tank will increase the back pressure on the head. I installed one on my compressor it nearly doubled the cycle time. Honestly in my opinion with the tests I did on mine a after cooler is better off post tank.

is the head and deck surface flat? you might want to double check that

I’ll clean them up and run a straight edge over them, but honestly whatever condition they are in the new head gasket is going on and it’s getting bolted back together. It didn’t look warped to me at first glance, but I didn’t take a particularly close look beyond the blown gasket.

I had a two stage given to me with a blown headgasket. Surfaces appeared flat to me. I went through 3 or 4. Tried flattening surfaces. Tried coppercoat. They just kept blowing out. Finally gave up and put a cheap v twin cylinder on it from harbor freight and never looked back. 160 bucks for 17.3 cfm at 90 psi and 145 max operating pressure. Been using it several years and been rock solid.

I’m using the same pump. Has worked well for me.

Been real busy the past week but I did replace the head gasket about a week ago, running like a champ and substantially quieter. Still looking to get a second compressor, this one only runs 11.5CFM@90 and I have my eye on a Quincy QT54 that puts out 15.2@175. That would give me more than 25CFM which should be enough to keep up with the blast cabinet.

I presume that this is still working well? Simple and cheap. Pictures of the inside would be nice.

It works very well. I am very happy with it. I have been cutting way more than ever before and I am very happy with the peace of mind I now ha vfd e with the air system. I will try to get some picks of the inside in the near future.

@Sticks Here is a video of my diy refrigerated air dryer. Works amazingly well and super cost effective!! let me know yalls opinions. For the guys that are not fans of pex for air lines…I have already taken those suggestions into cosideration. As always copy my ideas at your own risk…i do use alternative products in unique ways and dont suggest you do the same, however if you choose to be safe and use common sense! This has drastically extended the service life of my consummables!

that is pretty darn cool…I love the fire extinguisher part

Thank you @toolboy

Here is a link to the fire extinguisher build if you haven’t seen it. https://m.youtube.com/watch?v=el5HPRgSBeA

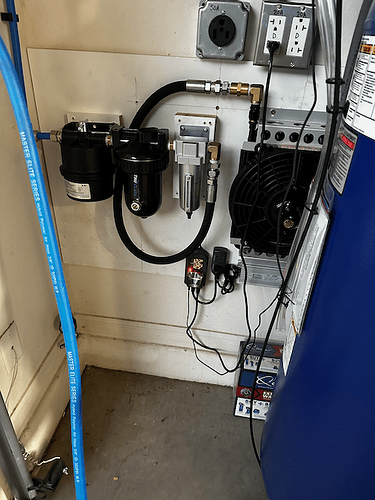

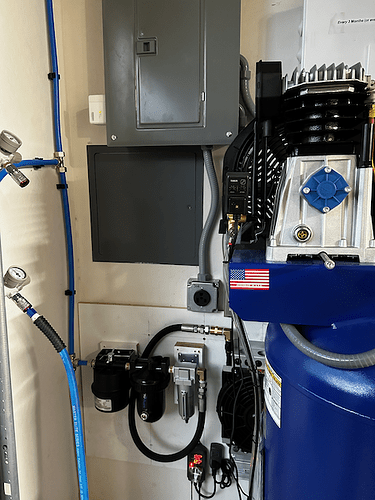

I completed my air system. Everything works great with a few exceptions. The timer switch is wonky, need to try a different one. It works but the light don’t stay on. Not sure why, because it is wired correctly unless I’m missing something. Two, the AN8 connectors leak. Hard to tighten without twisting the copper pipe. There were no other leaks.

In the pic I added the dissecant can to complete the system. I still haven’t put together my crossfire yet. LOL. Priorities. But I did use my handheld cut40 plasma with it and it worked great.

nice and tidy…my question is what is the inside diameter of the couplings on the blue pipe connectors?

yeah, well, that is a rub. I purchased the ½" kit but the inside diameter of the fittings is closer to ¼", so I guess they market it as OD, not ID. Which is scammy because the other pipe fittings are ½" ID. In any case, I’m not concerned because this will feed my cutter sufficiently and I’m not a production shop. But its annoying.

Another Shop with no dirt! ![]()

I swept all the dirt from the corner to other parts, don’t worry… ![]() j/k I am a card carrying member of the garage organization club…normally.

j/k I am a card carrying member of the garage organization club…normally.