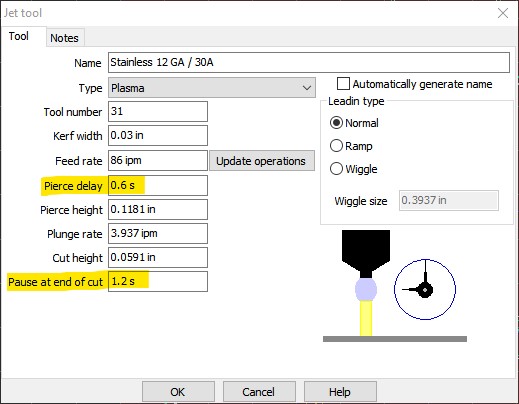

Found a setting called “Pause at End of Cut” in Sheetcam looks like it might workaround torch pierce timing issue I’ve been having. Don’t know yet if possible to do a similar pause in Fusion360.

This lets you set a pause after cut. It inserts G4 P1.2 code after every section of cut - so if you’ve got a piece with lots of pierces, you could start cut with normal .5 or .6 pierce delay (based on material thickness) so you don’t blow too big a hole and it will wait for 1.2 secs (in this example) when done so the torch can do it’s reset for next fire. This may prevent the guessing on pierce delay.

I’m going to test this in my next cut run, but hoping this will make for more accurate pierce delays. If anyone knows how to do this in Fusion360, much appreciated!