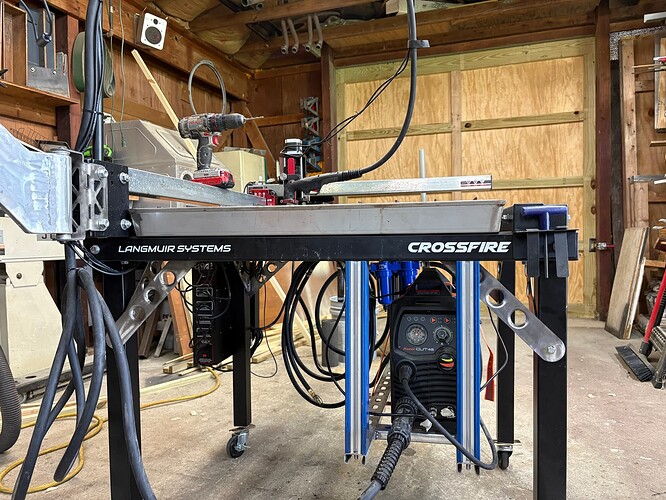

I added braces to the legs of the crossfire table.

My workshop is relatively small, and I need to keep it available for different types of projects, (Jeep and motorcycle work, woodworking, welding, etc). Also, the concrete floor of the shop is in really poor shape. As such, most everything in the shop is on wheels, and where possible, I’ve used larger diameter caster wheels to accommodate the uneven floor.

In moving the Crossfire around, I’ve noticed the legs tend to flex a bit when navigation over uneven concrete. This is worse when the water table is full.

To try and mitigate the problem, I cut a set (8) of braces from 14ga stainless and bolted them between the legs and table frame horizontals. I also dimpled each brace to add stiffness.

Although I didn’t take pictures, I also made a flat brackets (approx. 1”w x 4” long w/ a 5/16” hole in the middle) from 14ga steel and welded these to the base of the treaded stud on the 4 table casters to make it easier to level the table when necessary. If you zoom in on a few of the pictures you can see them.

I included pictures of the laptop holder I made a few months ago. The arm and tray are aluminum, and the bracket attached to the table frame is 14ga stainless. The arm and tray each pivot.

4 Likes

Ensure that the laptop stand is wholly isolated from the table chassis. Other than that, very nice.

2 Likes