I need some help if anyone has had this problem. I’m running the thermal dynamics cut 42 with the crossfire pro model, with the THC. The program will run fun with fire control but arc won’t start for around 3 seconds into the program running. I tried to set my delay longer and it shuts me down on the cut. I haven’t been able to have a successful clean cut yet

welcome to the forum…there are a lot of people here with plenty of experience.

I did a quick search on the forum and found this for you…there might be some information there to start

I have tried the above comment but when I put my torch delay to long it shuts the program down on me

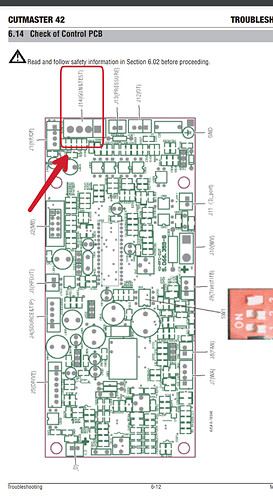

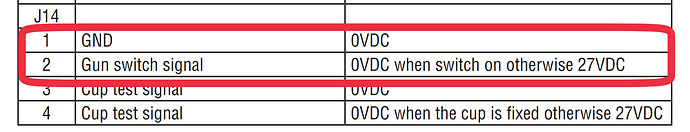

Thermal dynamics cut 42 manual

Thermal dynamics cut 42 service manual

Just a couple manuals for context in case somebody in the future runs along with post.

Is this where you hooked into your trigger contacts?

What program did you create the tool path in?

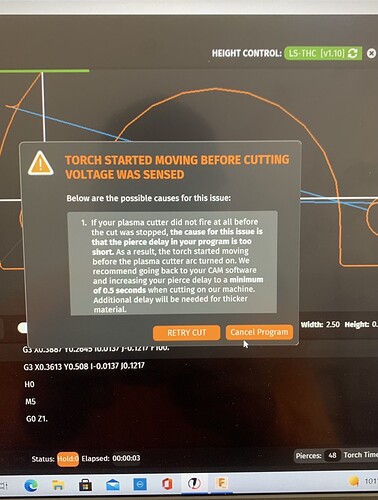

Does any error codes pop up on the screen?

Could you post your cut file?

Does the torch work properly manually?

What have you cut to this point?

Welcome to the forums.

If you can Screenshot your post settings in either sheetcam or fusion360 that might be helpful.

Yes I hooked the torch up properly to those points and it shows my thc is working on the screen. Also the error code appears on the screen when beginning to run program. I can fire the torch manually with no problem at all.

Can you quote or screenshot the error message that appears on your screen?

Try just running a straight line cut program through fire control with no torch height.

I try to change pierce delay and it does the same thing. It’s so frustrating

Were is your work clamp/ground connected? It must be on the metal “not” on the table or slats. The work clamp is positive and the torch is negative. The controller must sens a complete circuit or it will give you that warning

I put the clamp directly on the material I am cutting

You changed the pierce delay in you CAM software to north of .5 seconds?

Which CAM software are you using to generate your tools paths? Sheetcam or Fusion360?

Could you post a screen shot of your post screen.

Can you post your .NC file?

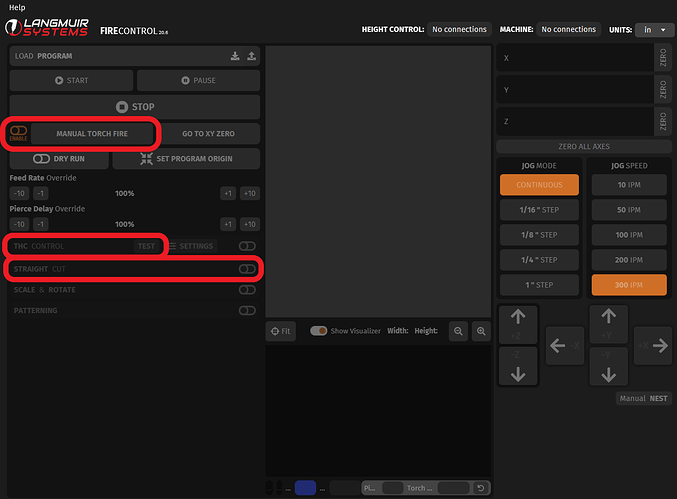

Can you manual torch fire from fire control?

just to be clear not holding it and firing it off the table. firing it through the software.

Have you gone through the THC test successfully?

Can you straight line cut?

Yes it will fire manually through the software with no delay. Soon as I run a program it has 3 second delay. I’m running fusion 360

This is a quirk with the Thermal Dynamics Cutmaster 42, I had the same issue when I first started. That machine requires a much longer delay for the very first arc start, then as long as the air stays blowing the second arc start happens much faster. I use Sheetcam and reached out to Les and had him walk me through modifying the post so that the first pierce always had a 1.5 second delay, and then all subsequent pierces had a .5 second delay. (Don’t quote me on those exact pierce delay times but it was close to that). The major issue I had was if I needed to pause the program to remove tip ups and the air quit blowing I could not restart because the first pierce needed such a long delay. In the end I ended up switching to an HTP plasma unit and use the TD for hand cutting only.

U wonder y they would put it in the specs to be compatible if it has problems. I feel like at this point I waisted money on the plasma unless anyone might have a fix to this

@Garagewerks , so for instance if you draw a simple circle to cut, let’s say out of 1/8 in steel and you set peirce at .4 seconds that it won’t finish the part before the warning appears?

If I set my peirce too long using firecontrol I get the same message as you do. Thats how I figured out my peirce delay was 7 seconds in my post process on a file that wouldn’t cut. It kept saying exactly the same thing as yours did. When I went back to look at the drawing I had put 7 seconds in instead on .7 The lack of decimal got me.

I had a similar problem. I was cutting 11 ga. Cutting bolt holes first then cut the outline of the piece. It cut the holes fine, then when it moved to cutting the part out, it would error and say arc not detected. I then would try it again. Same thing. I then chose retry cut, set it up to retry the same cut again. I chose manual fire and it would fire, then quickly chose run program. It would then continue to cut the piece. Error work around. The next new program cut i did never had an issue, only on this one item