Please, please, please add a check box to allow us to program the angles in as the non-included angle. I’ve been running tube bending equipment for years and having to remember to convert is bound to catch me out again sooner or later. It’s not the end of the world if I want a 110° bend and it gives me an open 110° angle because I can hit it again, but the other way around scraps a part.

LOL I just did that myself today.

We love our Titan 254T.

However, we patiently waiting for metric system support and other UI and usage improvements like increased button sizes and ability to NOT CANCELIING the bend when pedal is released during mid bend.

I agree, the safety behind the foot switch operation should be re-worked. I’d like to see

- remove the double-tap start

- foot off switch during bend is a “feed hold” not abort.

Use soft or hard limits on the ram piston travel.

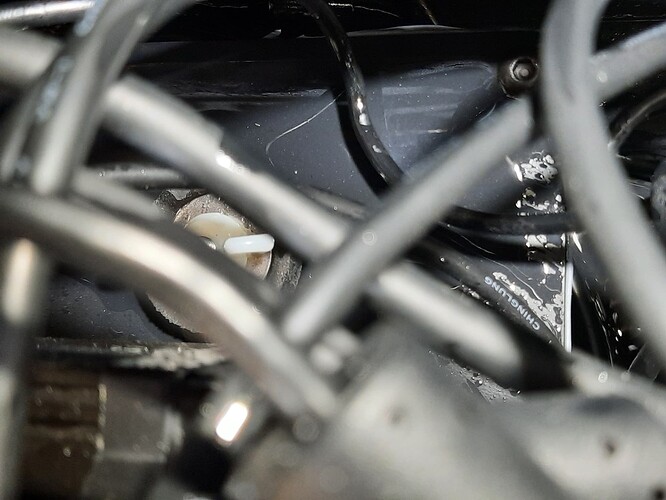

I was shooting a video today and manually jogged the ram down. Exceeded some mechanical limit, hard some disturbing new sounds, motion stopped and got a error screen message. Re-homed and I was back in business. Came back about 10 minutes later only to notice hydraulic oil all over the press base. Oh Joy! Popped the top, one of the hoses, attached to a hose barb (no clamp) popped off spraying oil everywhere. Oil on the tank, down the front, in the base, sprayed on the cabling, etc. You’ve all heard these horror stories before. Double Joy!

Oil drains through a gap for the electronics mounting plate.

I started cleaning my punches and dies, using acetone and paper towels. Went to clean the base and took off the painted logo. Triple Joy! Needless to say, I was livid at this point.

Next, went to take photos of the enclosure inside. Remember, I’m livid and my hands are slippery with hydraulic oil. Phone slipped out my hand and exactly fell between the hydraulic tank and display. Quadruple Joy! At this point, there’s just so much joy in my heart, You had to laugh, what else can you do?

It’s my fault really. I assumed (from my many years of experience working with CNC equipment) that hard and soft limits are implemented to keep stupid operators like me from damaging my machines. Well, that’s simply not the case here. So let me make a simple request to @langmuir-sam and the rest.

Use soft or hard limits on the ram piston travel.

This is an excellent de-greaser, won’t remove paint or damage ‘most’ plastic. Better than a solvent like acetone or thinner.

Thanks, I’ll pick up some.

I made some bends today - no pop, no hard limits, no problems at all…except for a large puddle of OIL dripping out the bottom screws of the electrical enclosure… haven’t pulled the top off yet, but i’m sure there is going to be OIL EVERYWHERE…

Placing sensitive electronics, drivers, power supplies and all the cable plug connections directly inside an enclosure with high pressure oil …without a divider or separator of any kind…seems like a horrible idea. not looking forward to this at all…5th round of buyer remorse creeping in

Might want to double check, but I think this is a corrosive. That wont be good long term on electronics.

Thankfully this is the sort of oil you could dip your electronics into and they would be fine. You will still want to wipe up the worst of it. A bit of paper towel with some alcohol or just some blown air should do the trick.

Once you open up the box and find out if anything is wet that is above the hydraulic fluid tank, shoot me a message and let me know and I can get you a solution if there is anything you should do. Hopefully this is just some leftover leakage through a tear in the silicone sealant on the lid.

I am not sure how this forum works, I don’t usually post in them. Another feature that would be extremely helpful would be the ability to increase bend speed beyond than 15ipm, it’s just too slow for a production environment where you’re bending 150 of a small part.

I removed the enclosure lid to inspect, and yes, it looks like the lid of the hyd tank is the source of the leak. I see the grey sealant oozed out in some places, especially around the tank bolts. I assume there is no gasket used here? and the seal is expected from the sealant alone ? ![]()

The oil level is approximately 2" from the top through the fill hole. IDK how much the pumps shoot oil around inside the tank, but it’s not over filled.

I see the tank lid top is the attachment point to the enclosure on two sides with 4 bolts. Since you suspected this was the source of the leak, I assume this is a common issue and I’m not the first or the last to deal with this.

Do you have a procedure documented to distribute or a video on how to repair this ?

Is there a drain procedure to get the oil out of the tank- disconnect “X” line and use the pump to bleep out the majority of oil from the tank and lines before taking the hard lines apart?

It looks like the tank and pumps/motors will come out in one unit, then the scraping/removal of the old sealant, cleaning and install a new gasket with sealant.

Please tell me you are using some sort of EPDM or BUNA-N gaskets for all of the machines shipping out now???

If you let the sealant cure 50% before tightening the bolts down, the sealant would have a chance to do it’s job, instead of tightening the bolts down 10 seconds after application and all the sealant oozing out of the joint, leaving a razor thin amount of sealant to do the work of a gasket.

I stuffed a diaper in the bottom of the box for now to soak up the mess and stop it from leaking all over the machine. It’s not just a few drips, it’s a puddle. Thankfully none of the boards or electronics got oil on them.

Now that the unit is stationary, you shouldn’t see anymore of a leak. That was just from the sloshing of the oil during shipping. The pumps do not significantly churn the oil so there is no repair needed unless you plan to ship it again.

We fill the tanks to 2", but they can be as low as .75" and still function. Since we sent out your unit we have changed the type of sealant we use to a more heat-resistant one which has helped.