Aside from the plate being level/parallel with the carriage (build up on slats, missing teeth on slats - I have new-ish saw tooth slats installed)

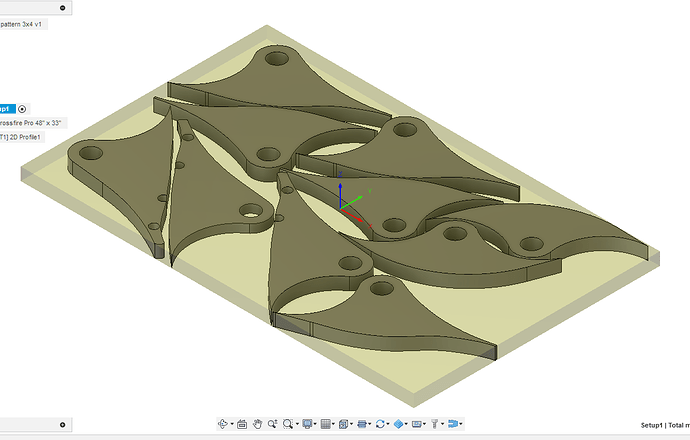

I didn’t think to get pictures when I finished, but I had a 3’ x 4’ slab of 1" plate on the table to cut out 10 of the pieces that I needed.

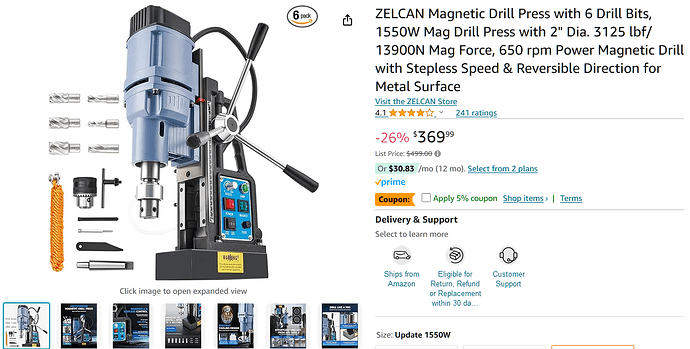

I plotted and pre drilled a .130 well .100 hole for each start (broke more number drill bits than I wanted with the cordless drill) with this…

…that I specifically got because of the long travel, MT2 arbor that can use the drill chuck, Weldon chuck, or any MT2 drill bit. That made things much nicer. - Also reversible, and variable speed. Might try tapping with it.

Lessons leaned - #1 when cutting thick stuff, .15 spacing is waaaaaay to close. The arranging put them too close and the torch would flame out and I would have to either limp along at 40a until there was enough meat to keep the torch lit, or pick up again when the arcs swung away from the neighboring part.

#2 - Home the machine after every piece, and verify placement of torch before the next cut. Kept loosing steps somewhere in X and Y. So what should have been a pierce in a pre-drilled hole (which worked awesome when it lined up) turned into an attempted 1" pierce which is a bad thing. I should have moved to the next point, marked it, then drilled rather than all at once.

#3 - My air compressor is not happy with me. Running non stop for each cut for the most part. Total on paper cut time was 1:23:19. Roughly 8.3 cut minutes per piece, not including flame out and other starts, then the additional time after the cut and post flow to get back to 150psi. I did wait for a few minutes after the compressor shut off to give it a rest. Total work time of 3 hours from plate placement to part removal.

#4 - The Pro water table sucks. Too shallow for this big a plasma, and the darn sides - promotes water exiting, not staying. 15 gallons overall on the floor and evap…Anybody come up with a splash guard yet? I also developed a leak at the seam. Now I have to pull it apart and re-seal it. May look into a sheet metal shop to build a one piece, and 2" deeper in the center to countersink in the frame. Depending on cost. I did keep a couple of pieces of 1.5" 16ga angle to sick along the sides when cutting, but when the torch was cutting above the slat bracket…RAMP to the edge, then RAMP to the floor.

#5 - Sharp U-turns are not your friend. The cut patterns have points on them that I should have cut off and given myself a 3/8 radius or square end.

Now that I have the cut height and speed dialed in, I started with a virgin set of consumables, and I still have life in them…I think. I did not look as it was coming up on quitting time and I just wanted done. The last piece cut has nice edges on it. The only thing that I trashed was a shield - from trying to pierce 1" in 1.3 seconds.

A little disappointed with the cut speed, but it cuts. Landed on 8.5 ipm as a compromise. Seemed to be cutting better towards the end. Hypertherm stated;

I would say the mechanized cut is still going too fast. The cut chart is below. The recommended cut height for mechanized is .125” you can try dropping that to as low as .06” but it might shorten consumable life. If the table has water in it, I expect to cut about 20% slower than book speed as well. As for edge start the starting and ramping up power can be kind of typical because the larger power arc has trouble establishing and starting to transfer at full power starting with about 10% of the arc touching the plate at the start is a good starting point.

Their math states I should have achieved 14ipm. 12 ipm gave me the bad tapers. I have some die plates for my 20t press to cut out of the 1" plate drops so I may experiment with speed a bit more.

I also have to find out what is going on with my THC. Voltages were anywhere from 72 down to 8.

RE #2, I had on several occasions lost position after a flame out and work zero shifted 40 inches X and 15 or more Y (end of travel and crashed). Not the first time either. This has been a problem that keeps popping up on cut failures since I got the machine, but I can not duplicate it on demand. Just cuss, home the machine, the go back and either set or verify the work zero before moving on.

Another odd one is when I need to start a cut from a line in the gcode and generate it, it will sometimes not have the torch start code in it, and the torch speed is increased a lot, like 8 imp program to torch moving at maybe 100. Another one I can not duplicate and should save the file before I start over with a fresh cut file and re-do the run from line.

All in all I only scrapped on piece, oddly the second one when the position shifted 1/4 an inch and started into the adjoining part.

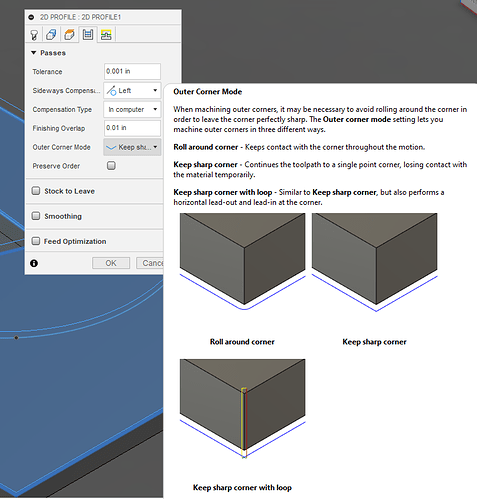

I don’t know how much this might have helped but both Fusion and SheetCAM have this feature with corners:

One inch plate is a whole different animal to tame.

So your saying the corner did not come out as expected?

I’m saying that the taper was meted off. Likely my kerf offset is too narrow with the 100 amp also.

@ChelanJim - I did have the sharp corner set.

Here are the plates that were cut. Some of these I wouldn’t give to a customer, but for what I’m doing with them there are more than fine. Just a little bit of touch up grinding here and there and will be good to go after I drill

the holes

This one shows how much that taper was supposed to be. I need to spend some time and verify my curfew offset for the next time I use this.

Ongoing side project

2001 Harbor Freight band saw. Smoke Genie came out yesterday. Waited too long to replace that capacitor. $160 and I’m doubling the horsepower with a replacement motor

Can you share pictures when you are finished? I build brackets and such for heavy equipment for my day job as well. I always like to see what others build.

So…yeahhhhh. Kerf width was off 25%. Almost did another when I was verifying them all and changed my sub .375 materiel to a .9 kerf.

It’s the little things that come and get ya.

EDIT - bad math

May want to add a vacuum under the table to help remove the chip and keep it from piling up under the drive wheel / gettin in places you don’t want conductive things…?

Won’t get used enough to be a problem, and it will get blown out during cleanings.

Back to the original topic -

The Good - Getting better at plotting the holes for pierces and cutting on 1". These were done at 75A @208v on the genset. Don’t know why it will not flame out on 208v but 480 I have to be 60a +/- to start the cut.

[custom die plates for my 20T press]

The Bad - However, even though it looked good from the top, I got greedy with the ipm and got that nasty taper I try to avoid.

The Good - My compressor is not happy with my cutting 1inch, and I knew it would be dicey when I bought it, so I grabbed the 5hp Vtwin compressor pump from Harbor Freight when it was on sale fall of 2023, and put it in over the weekend.

The OE compressor would hold kick on pressure and keep up. Which meant that it was running for 10-12 minutes straight at 115psi.

The HF compressor pump actually reaches cut out pressure and shuts down during the cut. Time from 110psi to 150 no load is 1:12 min. I did not time the recovery during cutting. Just surprised me when it shut off.

The bad - I was pretty sure the compressor that I bought was rated as a “5hp” with the higher cfm. It is actually a 3.7hp and now it pops the thermal overload after 45min of cutting. Now I gotta put a bigger motor on that one. Should return that bandsaw motor I bought and put this one on. TMTT would be all for it.

@Phillipw here is one leg.

That cylinders for steering on this four track unit. It has the ability to do side travel, and the OEM cylinder eyes are insufficient, so often when we’re going Side Travel we have zero steering. These additional eyes give us more options for moving the paver around

That’s awesome. I like playing with big toys .

I say, any piece of equipment that has its own catwalk is a piece of equipment that… hmmm, I NEVER had a piece of equipment with its own catwalk! I need to speak to someone about this! ![]()

46’ wide, 48’ front to back.