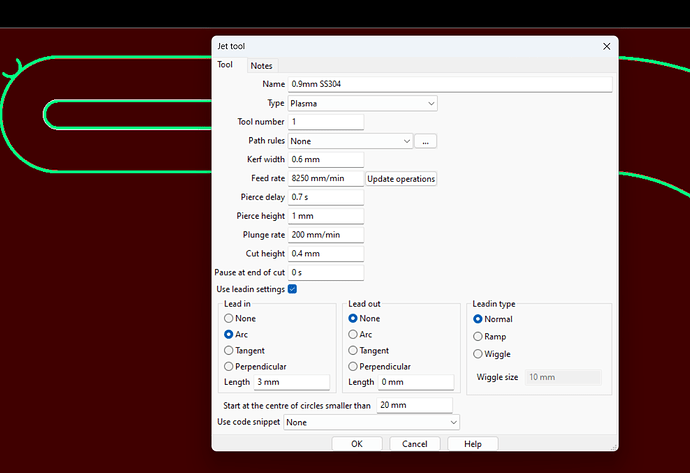

Hi, Ive just got my machine up and running and have made a few cuts this afternoon but getting frustrated. Ive been around in circles a bit. I am cutting thin stainless, which is probably not a great material to start on, however its kind of what I brought the machine for. My cut settings are below. XP45 and THC. One problem Im having is even thought he pierce delay is set to 0.7s as recommended with the Hypertherm, I am experiencing a much longer pierce time, 2-3S. I am wondering why this is occurring, and also sometimes I feel like this is causing the arc to stall and then the machine errors as the plasma is sitting there blowing the material, which is vibrating from the air pressure - I wonder if this is causing the error? My sheetcam settings below as per the manual. Ive had some ok cuts earlier in the day but appear to be getting more problems as I go along. Earth clamp is fine, IHC appears to be working, mostly…

Also I am running a hand torch and fine cut consumables, my machine has the CPC port but because I have the hand torch I have spiced into the switch wires for torch triggering.

Ive changed consumables afew times to ensure that isnt the problem

Your plunge rate is way too slow and that is why it seems that the pierce delay is too long. It won’t start the cutting motion until it lowers to cut height and it is taking longer than necessary with that plunge rate.

You currently have it at 200mm/min and it should be at least 1500mm/min.

Another thing that should be noted is the max speed for the Pro table is 300 IPM or 7620mm/min.

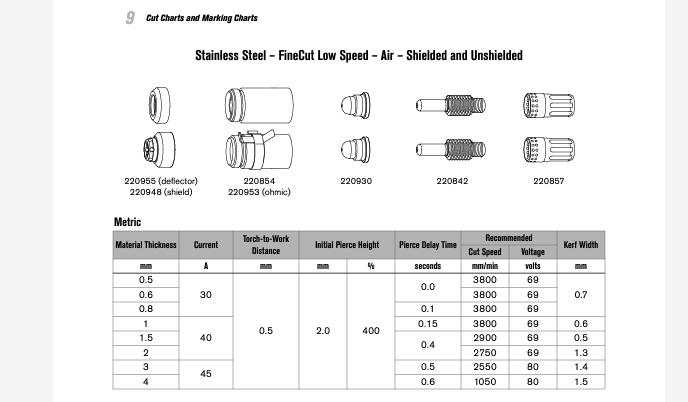

Which cut chart from the 45 XP book are using?

Depending on which cut chart you chose:

fine cut consumables high speed

fine cuts consumables low speed

I would you use recommend the fine cut consumables high speed unshielded cut to start.

Hypertherm cut charts are also in metric.

Here’s a post from a while ago where I did a 20 gauge stainless square to round.

Fine cut consumables work amazing on stainless.

Be sure to start with the book chart

Cut height on stainless is usually a lot closer and makes a massive difference in cut quality.

I would check your cut chart again it’s probably more like .1sec in the chart 325ipm 25am .02cut height .08 Pierce height. Because the pro can only do 300 in per second I would Max it out there.

I moved from a pro to XR and it is sure nice being able to type in .1 seconds and have it actually fire the torch unlike the pro. The trigger circuit latency is a good .3 seconds faster on the XR.

Thanks for this, I could not find any info on the ideal plunge rate so upped it from the default 100mm/min in Sheetcam.

The feed rate I have is the book setting for an XP45 cutting thin stainless - good to know that is not achievable on the Pro. After I posted this I started trying out different amps and feed rates and have found that quality increased at both 35 and 40A with feed rates as much as 50% less (overriding in Firecontrol) started to have some really good results. Im going to continue to play some more based on the recommendations here. Thanks

Thanks Tinwhisperer, I was only aware of one cut chart form the manual - now going back I can see there is a normal and low speed chart. As mentioned in the response to DS690 above, I subsequently tried to lower speed and amps last night after posting this and that has made a big difference - I have been running the fine cut consumables high speed chart as you suggest, and have an unshielded torch, however as DS690 also mentioned the cut speeds recommended by Hypertherm cannot be achieved with the Pro. One question I have is the cut charts mention Voltage, but I cannot see how to alter the voltage on the cutter or in Sheetcam? Screen shot attached

You are correct re the setting, this is what I have been using, only in the far superior metric units ![]() (325IPM. , 0.02 pierce height, but it recommends 45A on high speed.

(325IPM. , 0.02 pierce height, but it recommends 45A on high speed.

Thanks for your help.

The voltage from the chart can be used in the “nominal voltage” field of the THC section in Firecontrol. The THC will then use that voltage as the target when controlling the height of the torch during the cut.

Depending on the geometry you’re cutting you’re going to want to be dropping your speed anyhow. Usually full go speed on straight sections and 50 60% reduction for features.

Then switch over to the mild steel fine cut low speed air shielded and unshielded cut charts.

In my copy of the 45 XP manual high speed is listed as 40 amps 20 gauge or .8 mm. And if you only can go 300 in per second then I would go less amps than that to make up the difference.

Are you using the fine cut swirl ring? Part 220947 it only has a single row of holes

thanks, is this better than using the smart voltage?

Thanks, Im unsure how to reduce speed for different parts of the cut so will have to look into that. I can see with some of my experiments last night I was getting some weird bevelling at different parts of the cut. I have been working on the 1mm chart, but its a minor distinction (think it lists as 45A cut)

Im also not using the fine cut swirl ring, I was not supplied that with my machine even though I ordered fine cut consumables.

Ive just tried to do another cut now based on the advice here and the low speed settings but still getting a really lengthy pierce delay, even with the plunge rate increased to 1500mm/min

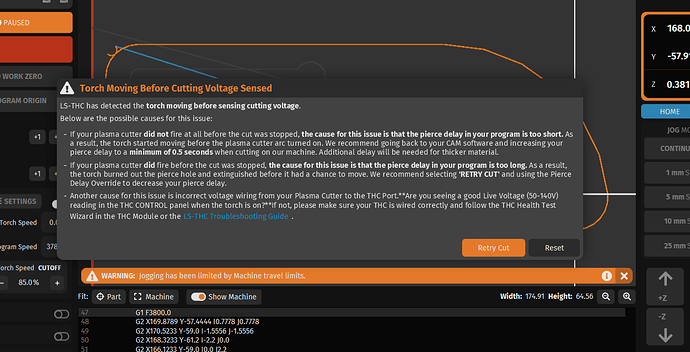

The first pierce is artificially long. The second pierce will represent your actual typed in Pierce delay plus the latency of the machine trigger circuit. Approximately .36sec. so if I was going to do a very short Pierce delay I would try to set my pierced time to .37 and have a piece of sacrificial geometry that I can cut first to use up the artificially long first Pierce delay.

The latency is also affected by the length of your torch whether a 25, 50 or 75 ft

You must use the hypertherm fine cut swirl ring for best results.

by artificially long you mean 2-3 seconds?? Basically I am getting it error out after that first pierce where it sits there and blows air for a bit before moving, at which point I get the error saying my pierce delay is too short. Is it possible that my dip switches for the voltage division inside my machine are not set correctly? Its a used XP45 that was used on a cutting machine, but this is something I havent checked and my problems all seem to revolve around the THC.

If I put in a 0.37 pierce delay I would get an error. I have a hand torch, so only short lead.

It was cutting well last night now this morning is giving me grief again

Ive just tried again. I get some success when overriding the pierce delay in Firecontrol, as low as 20%. Still getting the error though

I always use Smart Voltage, but I don’t have a Hypertherm. Hypertherm does a good job of testing the settings in their chart. As long as you can use the speed and amps in the chart, the voltage should be accurate. If you have to lower the amps or adjust the speed, stick with Smart Voltage.

No. It makes in a minimum of .5 seconds

And when you have such a close Pierce and cut height sometimes the material will spring back up into the nozzle and cause it to misfire or not fire. I find this happens on thin stainless the most for me.

On my pro.37 was the lowest I could program it for. Or I would set it for .5 and then a fire control I would dial it back too 73 or 74% of that

Now with the XR I can put in 0.1 seconds I think I’ve even put in 0 seconds before and it fires (but I’ll have to try that again, maybe I was dreaming about that )

I just cut a bunch of thin stainless today, using the straight line cut function in Firecontrol. I set the pierce delay at .4 seconds and it almost always burned out before moving on the first pierce. If I retried the cut while the post flow was still going, it worked every time.

I wish Firecontrol didn’t do that extra time on the first delay, but we just have to deal with it.

Im running 0.7 delay with the hypertherm, which is about .35 in reality from what @TinWhisperer is saying, and other info I have found. I just ran another cut and did pierce override of 10% and it worked pretty well. only one error and I just regenerated the code from that line. I have a feeling this is not going to be ideal for production of thin stainless parts with all these errors and nuances every time.

My most recent cut has yeilded a fairly good cut face with minimal bevel, but dross on the passes going in one direction which is odd…