So I was cutting some 1/2" plate on my XR the other day, and when i looked closer at the 3/4" holes i was making they were wider at the top of the plate then they were at the bottom. (Torch not square to table) We did square everything up when assembling, but upon further inspection we noticed that the rollers on the black square plate, that mounts to the red plate in this picture actually have close to 1/4" of play in them. I tried to take a video to upload to show what I am talking about, but it wont let me upload a short MP4 file. Has anyone else had this happen or Langmuir can you help me get this fixed?

Yeah, I just found another post on a crossfire pro, and saw the back two nuts are adjustable, I was looking at the front two and they are not. Sorry. Should have done more homework.

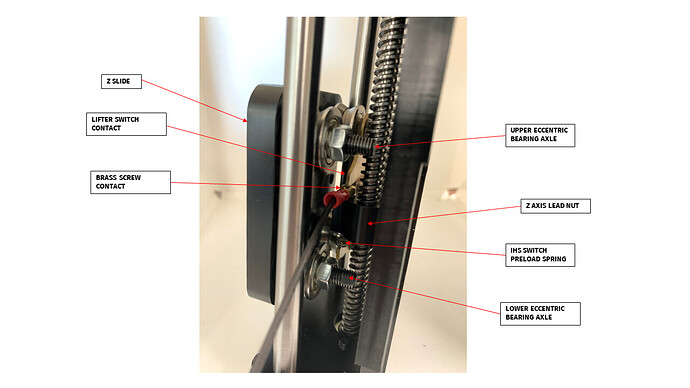

What you’ll need to do is figure out which of the jam nuts has walked loose, if not both. A quarter inch of lash is quite excessive. With a 5mm and 11mm box wrench, snug up, but do not overtighten, the jam nut to the bearing. Then, while holding the jam nut in place, turn the eccentric until you feel the lash reduced to little more than a few thousands. Do this in an iterative manner as you do not want to overtighten, which will lead to binding issues. Once you’ve sufficiently reduced the lash, use a hex key to manually jog the the slide to the extents to make sure your z axis moves without excessive resistance. If excessive force is required, hold the jam not and unload the bearing while still maintaining an acceptable amount of lash. Repeat this process until your slide moves freely and you have no more than a few thou of lash. Also keep in mind that while cutting thick material there will always be a slight degree of taper. This is an inherent characteristic of all plasma cutting as the cut is always chasing the torch as it moves. You can reduce the taper by cutting at a lower speed. Try to find the sweet spot between taper and dross.

I was hoping the XR differed from the PRO in this design, Im not a big fan of it, Iv had issues with it loosing up on my PRO’s alot. I do run big hypertherm machine torch and will not be using that torch on the PRO’s anymore. I personally have had to fiddle with it way too much. Once I get it nice and snug the Z axis hangs up, so its glitchy riding up and down. I have to loosen the bearings to where I can push and see the torch have movement, in order to not have my Z axis hang up. The XR has a little better X axis design but with all the play and eccentric bearings it can be a pain to get right. You really gotta know what you are doing, bc between that X axis guide unit being in or out of square and then the Z axis being in or out, it can be alot to track down.