Hey Guys ,

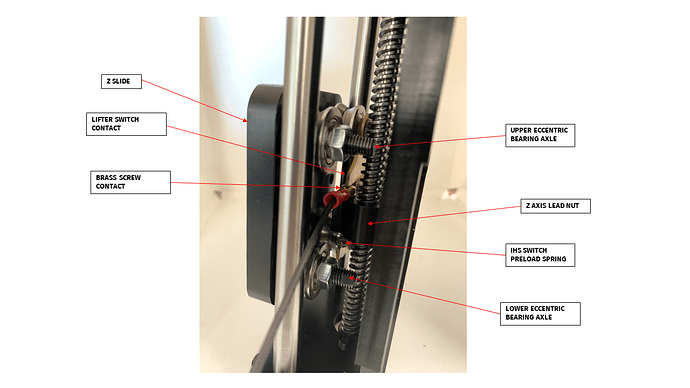

In squaring up our vertical Z axis a few things were observed. (Z axis is a factory assembly)

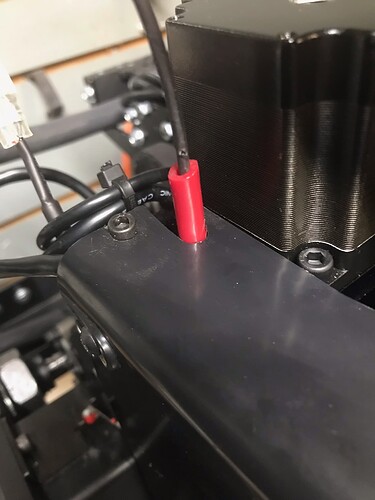

The touch off switch shrink tube over the wiring was abraded the due to the plastic guard edges rubbing. A piece of 1/4" od urethane tubing was slit and applied to better protect that abrasion where it travels vertically through the plastic guard.

Jogging the Z fully up can damage that touch off switch. There is no up limit switch or hard stop and if the guard is on you will never know it. Maybe our machine is different but this seems to be an issue.

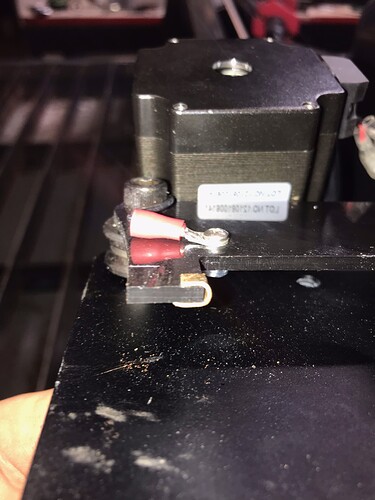

The touch off switch has a vertical plastic plate that is attached to the left side guide rollers. If jogged full up that plate contacts the lead screw coupling initially. Further jogging to full up the thin brass formed contact gets bent by the coupling ( that is spinning) deforming the contact. It actually looked like an L after the coupling bent it and rubbing on the lead screw.

Can someone confirm this is how their machine is configured? DO NOT jog it full up to test or you will be taking that Z axis slide plate off to fix that switch once bent. Without correction it likely can cause touch off height variations as the contact was originally bent into a U shape formed tightly around that plastic. Once bent not backed up and supported its more like a spring.

Tried to reform that brass it with some heavy duty forceps with out removing the slide plate but it looked like crap.

Removed shows the wear marks from coupling contact and the crude job of trying to re form it while it was assembled.

Removing the slide plate was able to squeeze it back into shape around the plastic backer not perfect but SB okay.

Stopping the Z axis stroke 9/16 from top of travel will correct it for now we have a stop block super glued to the top of the slide plate as a hard stop. I was tempted to put a heat gun to the plastic and bend it a little so it stayed clear of the coupling but wanted to put this out there before making any mods. Additionally if jogging full up the cable management on that switch is crap the wires can get pinched between the slide plate at top of the slide unit as you damage touch off sw. so hard stop seems to be easiest fix for now.