Oh you have no idea!!! She doesn’t have a moments peace.![]()

![]() .

.

Hi Rowen

I’m a novice at plasma cutting, but I have a decent brain in my skull.

With some more details we may be able to help you with your current set up.

Important things for us to know;

what control software are you using?

What are you using to create the gcode?

air pressure?

current setting?

material you are cutting

material thickness

cut height

air compressor tank size and continuous supply rating.

A few photos of your set up would help too.

Since few of us have the Yeswelder cut65, there aren’t so many people who can recommend settings, but we can try.

ps if you bought the yeswelder via amazon, you may be able to return it if you are not satisfied with the results. I had a yeswelder cut65. It was tripping my circuitbreaker all the time, then it went bang (literally) while it was plugged in, but turned off. I returned it and painfully bought a primeweld cut60. I think the primeweld may be the cheapest machine on here that people have consistently had success with. I’m not trashing your set up. I want you to be successful and I am sharing how I have trodden a similar path.

When trying to find settings that work for me I designed a 50mm x 50mm square with a few 10mm diameter circles in it. I used the free version of sheetcam to get the gcode. Then I cut several squares out. Each time I would inspect the cut, then change one or two parameters to test if that would improve or worsen the cut.

If you are able to consistently strike an arc and cut, I would recommend you try this method. You could even post here what your settings are and a pic of the output. Then those with more experience can recommend more air pressure/slower feed rate/different nozzle.

Good luck!

RowenMach3,

I purchased a CUT-65DS three Years ago and just tried it out. I was getting it assembled and

when I turned it on it’s side I heard a clunk inside. I removed the case and found a loose Coil on the Air Solenoid. I installed it and tightened the knob. I found a loose screw inside and put it in

my parts package. I tried it on 110 VAC, and it barley cut 1/16” steel with the flame 45 degrees

opposite the direction of travel. I then tried 220 VAC in the same piece of metal. I got a terrible

cut and I have attached a photo of that. I contacted YESWELDER and got Raymond. He tagged my CUT-65-DS as OOW since it had been 3 years since I purchased it. I got to thinking about

why it wouldn’t cut on 220 VAC while it cut a bit on 110 VAC. I removed the top again and looked

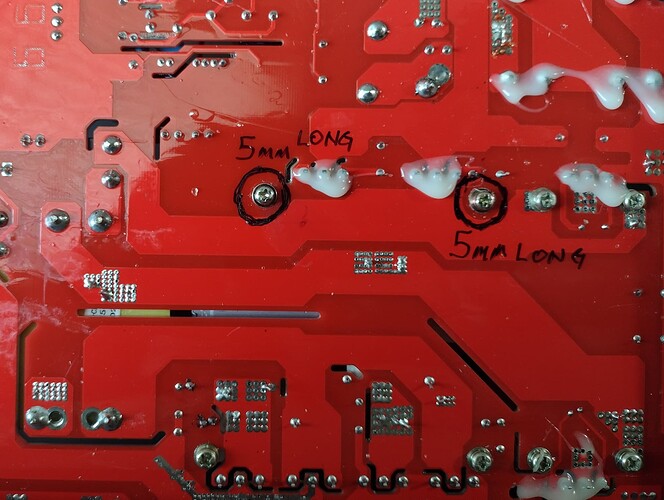

for threads in any empty hole in the PCB. I found one hole that had partial threads showing. Those were connected to a large Aluminum Heatsink. I loosened the other side and inserted the

loose screw in the threaded hole. But the screw wasn’t long enough to hold the part. I located

the small PCB in the upper right corner (looking from the back) and that PCB had 6mm Threads.

I replaced the 4mm long threaded screws with the 6mm long threaded screws. So, now the Small PCB had 4mm long screws and the heat sink had 6mm long screws. I shortened them to about 5.5mm long so they wouldn’t bottom out. After that my CUT-65DS worked PERFECTLY. It will slice through 3/8” bar stock using 220 VAC like Dental floss through Butter.

All because some Tech assembled the CUT-65DS with the incorrect screws to hold the Heatsink

which wasn’t making contact with the PCB. I bet YESWELDER has several Warehouses full of

CUT-65DS Plasma Cutters as returns with the Incorrect screws holding the Heatsink to the PCB.

A Simple 15 Minute FIX once you know what the problem is. So much for Case Histories for a

troubleshooting technique from YESWELDER.

Larry Kraemer

Chaffee, MO USA

For an update……

Completely forgot to check this thing.

I fixed the inconsistent problem by changing the torch. Instead of the junk 45 amp torch, I got a IPTM80 machine torch. Modified it to work with the machine and have had consistent cuts every time.

Consumables don’t wear out as fast either.

Thanks to those that made me aware of the 45 amp issue.

If they were heatsink screws then it would not make it work, unless when you put new screws in it caused what ever is on the heatsink to make contact. This may not last long as I would guess what ever was on that heatsink broke lose from the PCB and is now making contact to the PCB.

George,

I had been looking for a way to contact you from your Website to see if you had worked on a YESWELDER CUT-65DS, for some support. I only found your Phone number.

I wish I had a Schematic of the CUT-65DS so I could explain it better, and you could verify that what was on the Heatsink was the DC Voltage components, being cooled by the Fan. Each Screw that was Originally installed was too short to keep the connection tight to the PCB. With one screw with partially stripped threads the PCB didn’t get the proper DC voltage, therefore making a partial cut with 220 VAC applied to the Cutter. By inserting longer screws I got the full DC Voltage supplied to the PCB from the DC Heatsink, from a tight connection.

If you ever get your hands on one you will quickly see what they did to get the DC fed to the Motherboard.

I’m an experienced Electrical and Instrumentation Tech, who has worked on everything from 480 VAC down to +5 VDC Power Supplies, excluding 480V Lighting, Glycol Systems, and HVAC. I do have an HVAC Certification that I got after retirement.

Thanks for your Plasma Cutter support.

Larry Kraemer

Larry,

If you got my phone number then you can call me 9 to 6 eastern time.. Pictures of the board and the components that are on the heat sink would also help.

So I have the same plasma cutter and was wondering how to stop it burning the material away with cuts that are really close. I have turned the amps down turned the air pressure down. It helped but it still cut away

Do not turn air down, a plasma cutter can only cut so fine because of kurf width. Lots of information on subject if you search.