I have some of that too, but does not seem to effect anything. Now I did have some of that paint flake off and stick to the bearings on the X axis and I could hear some noise, but did not really notice anything in cuts. I think I might have had my bearings on the X set a touch tight. I don’t think any finish on steel would hold up to the rollers/bearings rubbing in the same spot. Maybe anodizing?

If you do go stainless, be sure and post some pics, I would really like to see how that turns out.

Stainless is softer than carbon steel but may bed in in to a nice spot no crunchy paint and crap biasing the micro-steps… For now we will work with solutions on finish removal and making sure we have a smooth finish . The STV machines run on hardened rails so you won’t see any discussions based on this issue with those machines. Seems this group does not want to deal their main rail guiding system finish fail like normal manufactures would.

It is the issue of not providing a warranty on power coating but then using powder coat as a bearing surface. Does it work? Yes, with some effort on our part to work around a rough finish until everything flakes off and beds in. My main gripe is a lack of clarity from the manufacturer about this design. Most everyone in the industry uses either linear guides (real ones) or ground tube/round stock of some sort with the kind of rollers/bearings that Langmuir is using. Powder coated, welded tubing is…unique. My XR makes good parts so the engineering compromises seem to deliver. Long term and heavy use? I hope it is durable but not wild about that one aspect of the XR and it makes it a little difficult to recommend.

I am looking at getting an XR and this does not bother me. At this point will either strip the rails when i get it or make new ones so not a huge ordeal either and juat add it to the several mods that will be done to it.

I guess it all comes down to what to expect for a table at this price point. I look at this, like every other piece of equipment I buy at the lowest price. I may have to rework it and make some changes to it to get it the way I want it. That will mean many different things to many different people. Nice thing I did not have to spend big money for a table that is built for heavy use when I don’t need that. What I can do if I find out I am going to use more like a production machine, is to modify it where it needs to be. And the nice thing I can make some money with it until I decide if it works for me as is or I need to make it better.

Personally that’s the part I like the best, improving on someone else’s design.

And I will say it again, I am very happy with my XR even if its not perfect, because I did not pay for perfection.

Just my 2 cents like always

A Vee roller contacting a round tube has basically point contacts 2 per roller and a bit different than the Y axis running flat faced bearings on a flat tube (if adjusted properly) so maybe they missed that contact pressure influence on the finish. Additionally there is mass and inertia as the Y moves in sync with X putting kinetic influence loads on the Vee rollers contact points no matter if they are tight or loosely adjusted. I was looking at building a machine and in research saw some some cats are running urethane guide rollers on square tubes with eccentric adjustment for backlash.

Go to machine control far right upper and dumb down the rapid advance too 300 IPM It does give a little extra time to pause between parts if you feel you need to take a short break and resume.

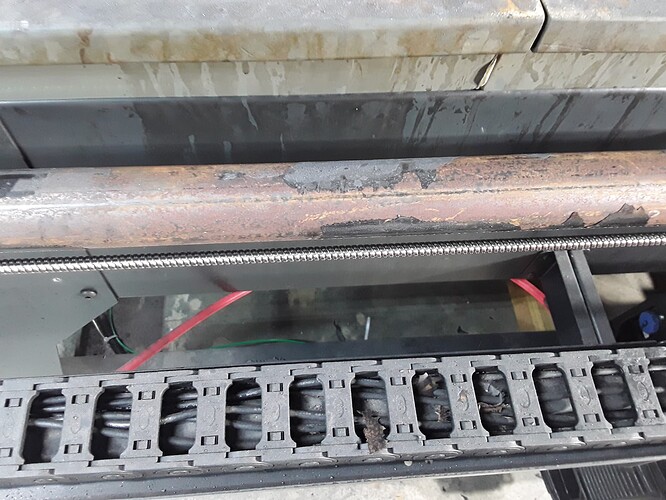

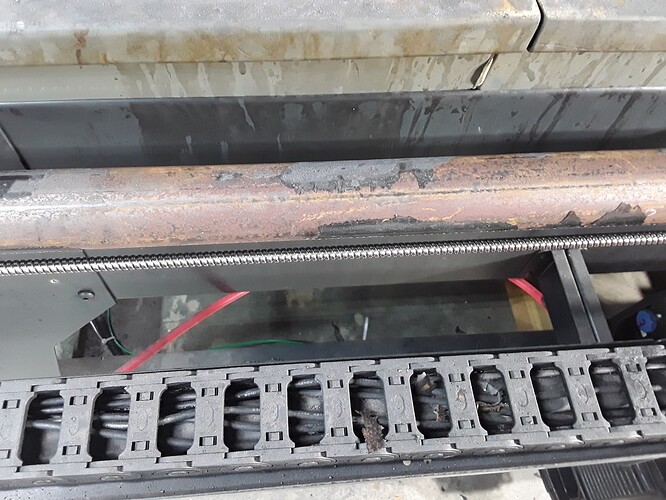

i am having the same paint related issues. x axis has finally worn most off. the y axis has a few weird rough spots in the paint. i dont think its an issue just a bit funky.

Our Y has already been scraped and dusted in semi flat Krylon. The X axis tubes are a different animal as it seems the material was likely purchased galvanized and top coated, so you end up with a lot more funk coming off the X guide tubes.

i ran some scotch brite with a dab of grease and it helped pull off alot of the crunchy paint and smooth the groove. then i just cleaned it off with a rag and it seemed to run a bit smoother.

are you still getting good quality cuts?

I have been dealing with this the last few days. Decided to strip all the powder coat, scuff and sand (120/240/400 then 000 steel wool. I know it’s probably overkill) and repaint with enamel paint. It should wear through the paint pretty quick and leave the rest of the tube protected.

Pretty shitty that we need to do this but + great work . Seems more than 1-10 has hacked up that monitor pennant as well.

Another paint tip is aluminum foil. I have worked with automation assembly equipment and some large GM assembly lines were being refurbished and that was the trend… Not everywhere but on some tricky spots foil works well.

If you get the gifted gator skin off you will be good.

So far cuts have been fine ,i have decided to use a pipe polisher to clean them of and polish them ,I’m eather going to clear coat or just wax them after polishing

@autotech Thanks. Thats a great tip. I’ll have to remember that for next time I paint