Need some help. Ive made a few things and all is going great. But today im trying to make a 18x24 sign and the fonts arent coming out right. Can someone send me in the rihjt direction. Ive read through the forums but im not finding anything that has worked for me. Thanks in advance

Can you post pictures of what you don’t like about it?

What amps are you running?

And ive tried 25 up.ro 30 amps. Its 14ga steel im cutting

Looks to me you are either to hot, to slow may speed up a little, or bridges need to be wider.

I ran a rw45 for a year. Standard consumables I would 35 amps and around 90ish ipm.

Ill try the 35 smps snd crank the speed up. Thank you

Now I was running standard consumables not sure how high amps yours are rated for. Running to high will blow you nozzle out. How wide are you bridges?

By bridges im assuming you’re talking about the small peices i. Burning off the connects the small part in the fonts? If so i didnt mess with any width adjustments for that. Not sure where to do that. I just picked a type of font snd ran with it

Yes that is the part. What cad program do you use. I would suggest measuring them there. If they are not at least 3/16 wide you are wasting material in my opinion. You may need to widen the out.

That is a nice font though. The first font you sued held up. I say it’s a bridge issue.

For my signs im just using inkscape

Using sheet cam correct? You can right click go down to measure zoom in some and measure bridges. I don’t do enough In inkscape to tell you how or if you can there.

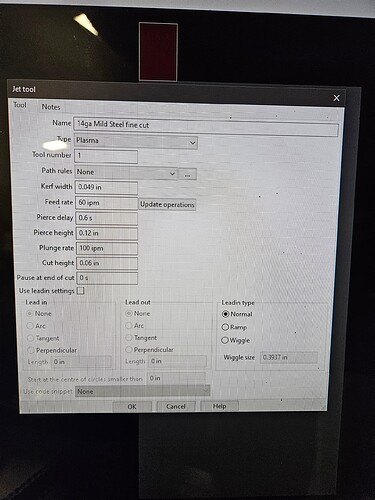

Yes i use sheetcam

Some is .06 and some is .085

You need to be double those in my opinion maybe more being outside sign. Is it going to have a back plate?

Yeah not sure how to do that. Ill have to do some research. Yes it will have a back plate. My big sign are no problems. Ofcoarse cause is a 4’x6’ sign

I can’t give you much direction on that I very seldom do anything with inkscape.

Pretty much you will need to draw lines wide than those and weld them together.

I do know lots of YouTube videos on inkscape.

Maybe some here can give you better pointers

I do know how to make changes, but it would be to each letter individually. would be nice to know how, if possible, to change all at once. thank you for all you advice. i will try a few thigs and change my speed and give it a shot

Sorry I don’t use Inkscape but sure they have similar abilities…

Design -

In fusion you can just select the letters and use contour. This will allow you to bring the outline of the letters in giving you more clearance on the bridges. Normally when you bring a font into the design you can add spacing between the letters right away. This won’t fix the bridges but will help between letters.

Cutting -

Make sure you’re using left compensation.

So, for inkscape you can select your lettering and hit control and ) or control and ( to change the outline of the letters, (make them bolder or thinner) that will change the whole letter though. Usually I just get my node editor tool, select all the nodes on one side of my bridge and move them all together. I usually shoot for a .1 or bigger bridge size.

Sorry for the late response. Works been hectic. Thanks for the input. I will try that too. I did manually work on each letter to widen the parts. A little time consuming but seem to work. Just working on a few other kinks now.