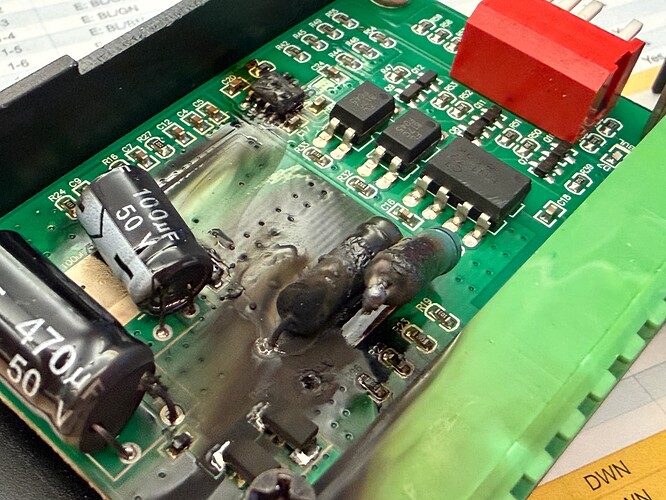

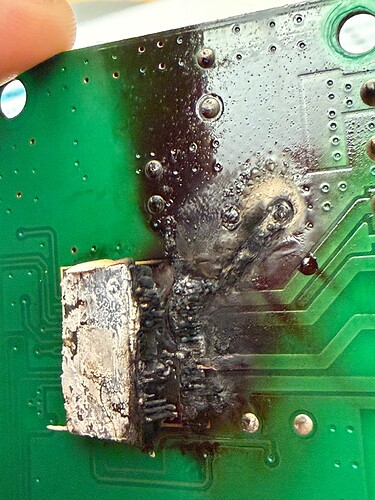

I had the Z Axis driver blow up. I replaced the Z driver and plugged the motor back in. I then went into FireControl and manually ran the Z motor up and down fine a few times. Without powering anything down I left. When I came back later it was blown up. I could smell it and manual operation from FireControl failed.

Pictures? Is it wired correctly? Test your power supply output.

Only the Z axis being affected is an odd one for sure.

Nothing has changed for the past two years. Been running great. Few days ago driver blew up. replaced driver and went boom again. Inside electronics box looks fairly clean all things considered. Figure my next step is to check power supply, although I would think the other axis would have a problem if the supply was bad. Then check for shorts in the motor cable. Odd it ran manually for a few up/down motions after i replaced the driver the first time.

Check your power supply output. It should be 36VDC.

I checked and the power supply is putting out 35vDC

I removed the Phoenix connector that goes to the 4 pin round motor connector and metered each pair. Red / Green = 1.5 ohm. Blue / Yellow = 1.5 ohm. Open in any other combination.

I also checked all pins to chassis ground and all open.

I also kept the meter on Red / Green while homing the machine and it stayed at 1.5 ohm. Same for Blue / Yellow.

I pulled the new driver out and opened it and it is not blown up like the last one and the LED is on but it still does not move and there is a smell of electronics burning still present.

X and Y work fine.

Check the pins where the motor cable connects to the electronics enclosure. Look for burnt pins in the connector that could indicate arcing across the pins.

I know it’s a long shot but is it possible there is something binding in the z-axis carriage? Pretty sure these types of motors hold position and they may be trying to hold a position they can’t attain. Does the Z on the XR have a driven ballscrew or a ball nut like the X/Y?

If I take the plastic shroud off I can easily with and without power to the motor I can easily spin the motor / screw

Stepper Motor power is not significantly affected if the motor binds. There is some effect but it wouldn’t be enough to burn out a driver. Only shorted windings (to each other or to something else), overvoltage, or defective driver would cause this problem.

Send these photos back to the tech that built these boards ( if possible). The tech may a short history written up on this exact problem. I used to keep a repair history notebook of circuit boards I built for a 110v & 220v generator system we used to build. Once I knew exactly which parts blew up (as you said) I could almost always go backwards from there to see what typically failed with 80-90% certainty where the real problem began that caused the catastrophic failure of certain components. Not a perfect system, but worked a lot of the time, making the repairs simpler and minimizing downtime.