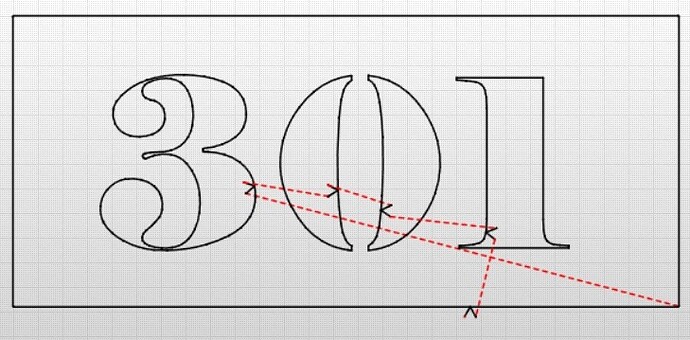

I am using the xr and firecontrol everything seems to be working right except the cuts are way off. Can anyone help please. Showing pics

Tons going on here.

Looks like a combination of incorrect cut & pierce height (too high), pierce delay (too short possibly), cut speed (too fast), moisture (huge issue for many), amp setting (too low in relation to speed), as well as possibly being on 4T.

If this is your first cut ever, I would go back to the basics ensuring your plasma cutter is set correctly, and that you instead perform some test cuts.

Test cuts will teach you how to operate your plasma table, figure out the correct parameters for cutting, fine tune your correct amp setting and cut speed, and most importantly learn the proper kerf value for said consumables used.

@loc2355 the major problem we have going on here is your losing steps in the x axis. I assume it’s the x axis or it would likely jam right up.

Using fire control to manually run your torch back and forth on the x-axis how does it operate? Is it tight , chattering, etc. any odd behavior?