Ive had the table set up, true and square. All X,Y and Z axis are true and suare. Ive chacked for rock or lashing and have adjusted.

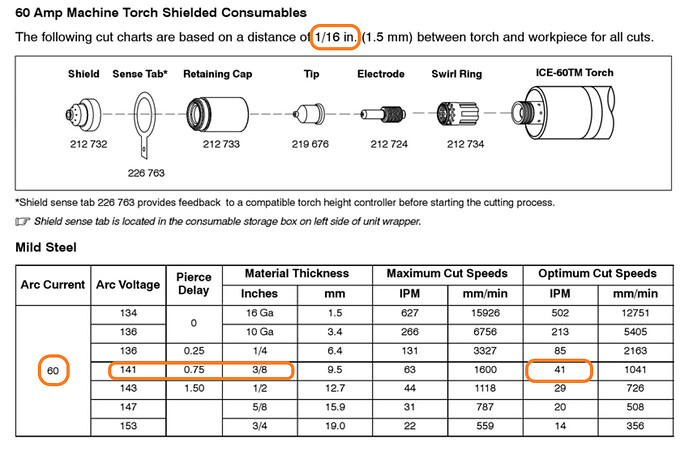

Im using a Miller Spectrum 875 with the machine torch. 60 amp consumables from Miller.

straight line cut @ 60amps, .09 pierce delay, air pressure is at 100psi and cut speed of 40ipm. The top cut of a 3/8 plate is just under .125. bottom of plate the cut is roughly .0598. see photo.

All parts no matter what gauge or amperage or speed cuts at this angle.

how can i correct this?

Also im using Fusion 360 for programing which has worked out great. However im trying to figure out if i can make my lead out pass the lead in to smooth the transition.

@Bogielski welcome to The forum

What cut height are you currently running?

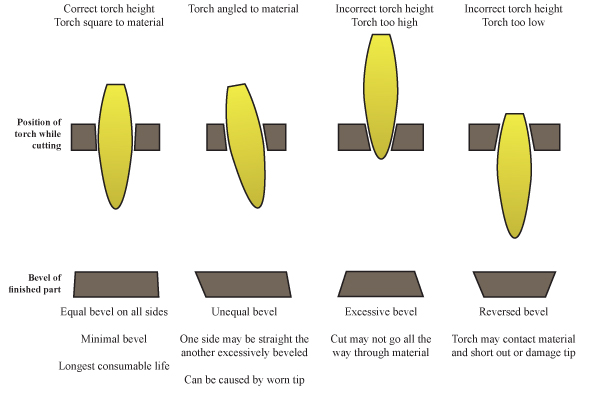

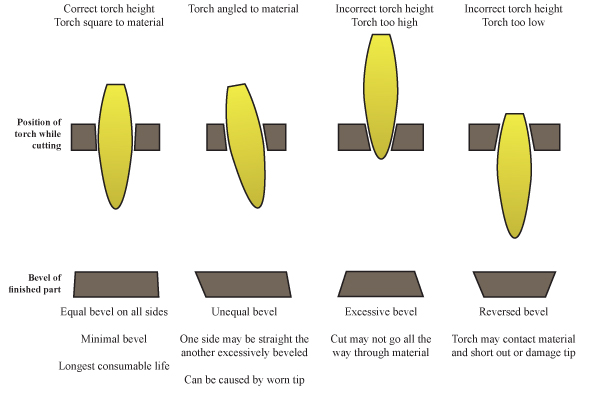

This picture explains why I’m asking about cut height.

How is the condition of your consumables?

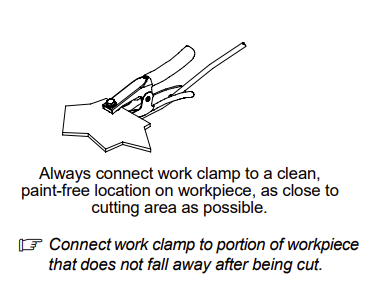

Are you locating your work clamp, on the material?

1 Like

New consumables, Clamp is clamped to the table (not workpiece)

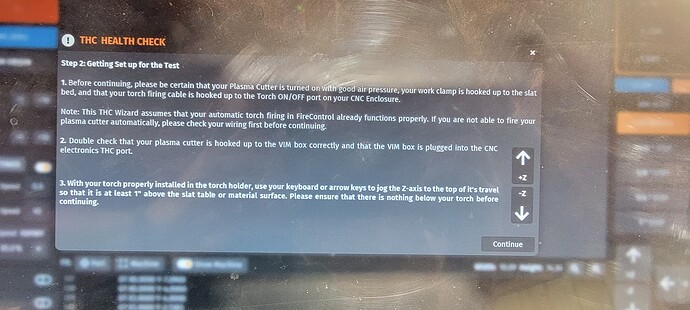

Using automatic THC with smart voltage.

THC settings are:

Nominal - 0

Tolerance - 1.5

Sample size - 50

Offset - .25

Distance - .25

Torch Speed Cutoff

Factor - 85%

Z Speed - 5%

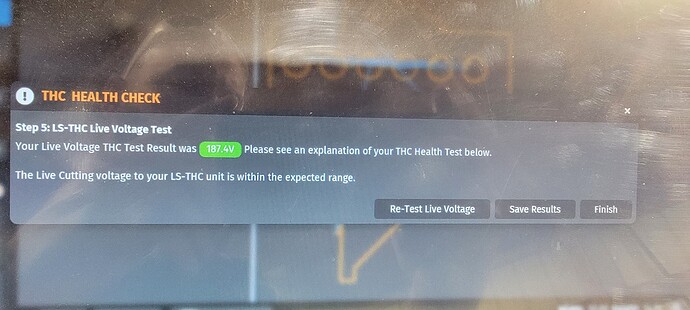

One thing i do notice on Millers manual is it says for 3/8 and a 60 amp consumable my nominal arc voltage should be 141. Im at 187. could that cause the THC to raise the head of the machine torch?

Should i try and turn off smart voltage and just run at Millers recommended nominal voltage?

so running smart voltage, I noticed it auto-adjusted to 140 to 142.

I tried it with and without the clamp on the workpiece and just on the slat and made no difference.

I think the straight line cut is auto set to .06 ? Not 100% of that though.

I am going to thumb through the miller manual and check out their charts.

While running with a 141 voltage written in to your nominal voltage does it look like its running at a 1/16 off the material while cutting?

you could try some feed operation and reduce the feed by 50% for the slots and holes.

1 Like

So where do you change the torch height? isnt the THC doing that automatically?

I cant reply because ive posted more than allowed for a new forum user.

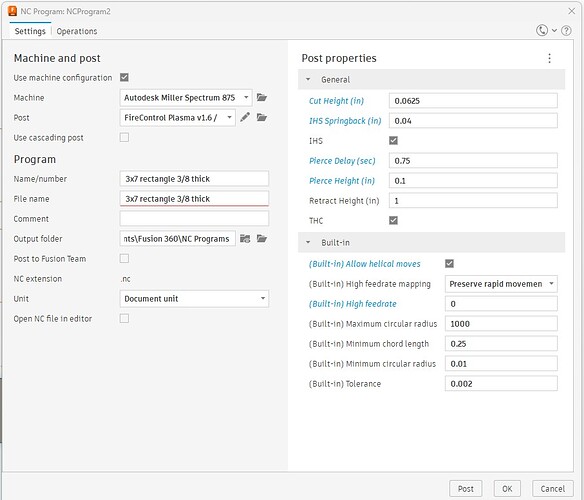

Is this correct?

Usually you have a starting off height that you would program in your post processing.

If you had smart voltage activated it would read The cutting voltage for the first few milliseconds and then maintain that cut height.

For nominal voltage it would try to reach the cut height determined by the voltage.

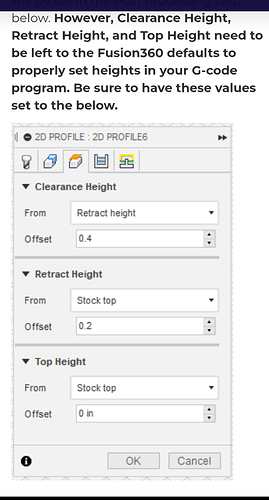

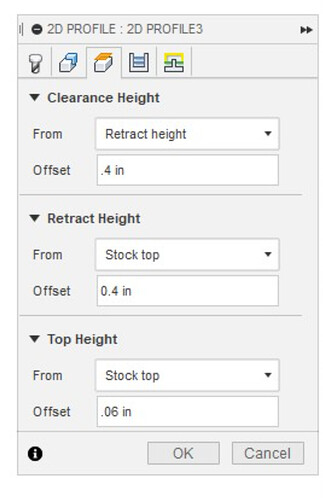

No, That’s the spring back and retract heights it’s in your post processing section.

Last page where you create your G-Code

1 Like

Try to match your values up to this on the retract and spring back

Your values are quite a bit different here.

No . Springback .02

And try just 0.06 for cut height

Increase your Pierce delay to 1.1sec. there’s about a 0.4second lag you can add to your chart cut value.

I think a new user is limited to nine posts on thier first day.

1 Like