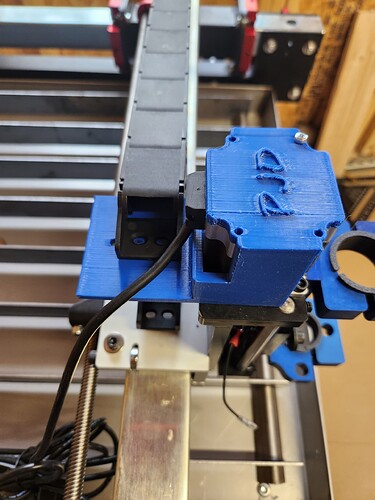

Added the cable chain, cleans up the cabeling, 3D printed a mount for the chain and also printed the torch cable mounts for cable bar.

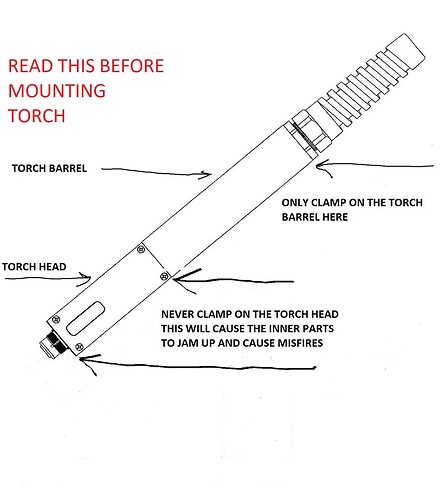

Just a word of advice. Your torch is mounted wrong you need to move the lower clamp off the torch head.

If you use Becks Armory’s laser torch holder, you must keep the lower clamp just hand tight—no squeezing. The top clamp will hold the torch just fine. He designed it not to crush the torch, but just hand tight will work. Or is that a 3D creation of your own design? If that’s the case, the thread above this one from @mechanic416 will be correct.

Thank you for the reminder. It is just barley on to mount the torch cable

It is Becks

I leave mine hand tight.

So at what level should the top clamp be? If i lower it where the bottom clamp is above the head i do not have much z travel

If you use Becks Armory holder, you are in a good position. Just don’t tighten the bottom clamp over hand tight. You will have plenty of Z travel either way. I love mine. Keeping the lens clean on the lasers is a pain in the ass. It is what it is. You need to try his breakaway bracket also. Super high quality. It will save the torch from unplanned tip up collision. @Richarddbeck83

Is there a switch that shuts off the torch if there is a breakaway? I wouldn’t want a live torch flopping around on the table…

I should point out that this question is academic as I have a different system than his one…

No, but it still keeps the torch intact. Hopefully, the operator can handle this problem. These tables are far from self-driving.

George gave me the same advice several years. Thanks George for keeping the group informed.

One nice thing about the Beck Tools torchholder is that it’s a round clamp, not two v-blocks. Unlike dual v-blocks it does not create 4 highly concentrated points of contact.

I personally have had my Beck Tools Torch holder clamped onto the lower part of my machine torch for over 3 years.

Because it has almost 100% surface area contact it takes very little torque on the bolts to hold it securely.

If you squeeze an egg from all size equally it can withstandand Immense amounts of force. If you tap it ever so slightly with a nail it will break with almost no effort. This is the same principle that is applied with the Beck Tools torchmount.

That assumes your DUT has homogenous hoop strength like an egg does…

I agree but there are people out their that can break a anvil with a wooden hammer.

I’m simply showing both extremes as and example to help people understand the principle. I’m not saying dual V-blocks have as much concentrated stress as an ice pick. In the same sense I’m not claiming my mount has a total homogenous hoop strength. I’ve already posted pictures of the exact FEA comparison between my mount and a standard dual v-block. I don’t feel I need to dig those up and post them every single time.

I pray every night I never sell anything to these people. lol Fingers crossed. I have made videos showing exactly how little torque is needed. I need to remake that video and post in on my product page.

Overall there are Pros and Cons. Dabbing the water off the lens at the end of the cut so it will focus is annoying but being able to pick up a point visibly from 6 feet away and line up a sheet super fast makes it worth it for me.

It was more tongue in cheek (enginerd to enginerd)

I added an E-stop in-line with the torch on/off circuit… so if and when it did break-away, I can press the e-stop and the torch would go out but the program might still run, which you can restart.

Also works great when doing consumable changes or torch inspections without having to turn the cutter off.

3D chain-mounts.zip (72.2 KB)

in case anybody wants the STLs