could be several things. Maybe to low amps bad consumables wet air. What are your cut settings? What gauge are you cutting?

16 gauge 30 amps

What speed are you using? Ground on the material?

How much cutting has your consumables done?

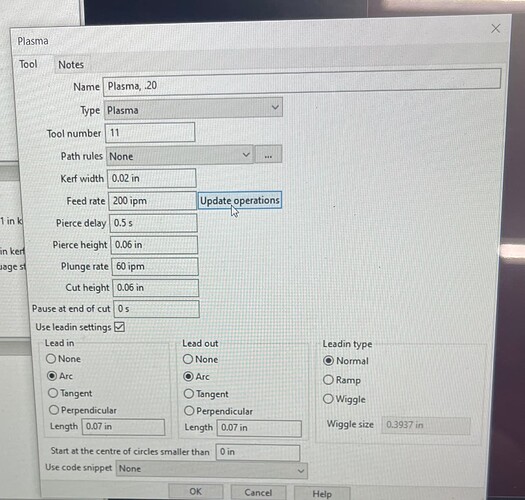

your running 200 IPM at 30 amps?

That might be a little fast for 30 amps

What plasma do you have

Razor weld 45

i believe that should be like 70 IPM. check chart

I’ll try it at 70 am getting new tips in today

When using my re 45 I cut 14 ga at 30 amps and 90 ipm which isnt much thicker than 16

. You may want to check your kerf also. Mine was more around .055

Ok I’ll check today and try it out

What air drying do you do ? Tips won’t last very long with moisture

i use 0.05 lead-in and no lead-out for almost everything. You might want to ask a few other what they use with RW45. i do a lot of cutting but seems everyone has their own little thing based off setup. You’ll have it dialed in soon.

Ok thanks i hope soon