So I have been out of the game for 3 years with the pro sitting in the box that it came in. I have just set it up and was wondering how to wire it up with out frying the THC? I have wired the Raw Voltage Pigtail Cables to the lugs at the front of the plasma cutter.

So is this the next step?

https://www.langmuirsystems.com/thc/guide

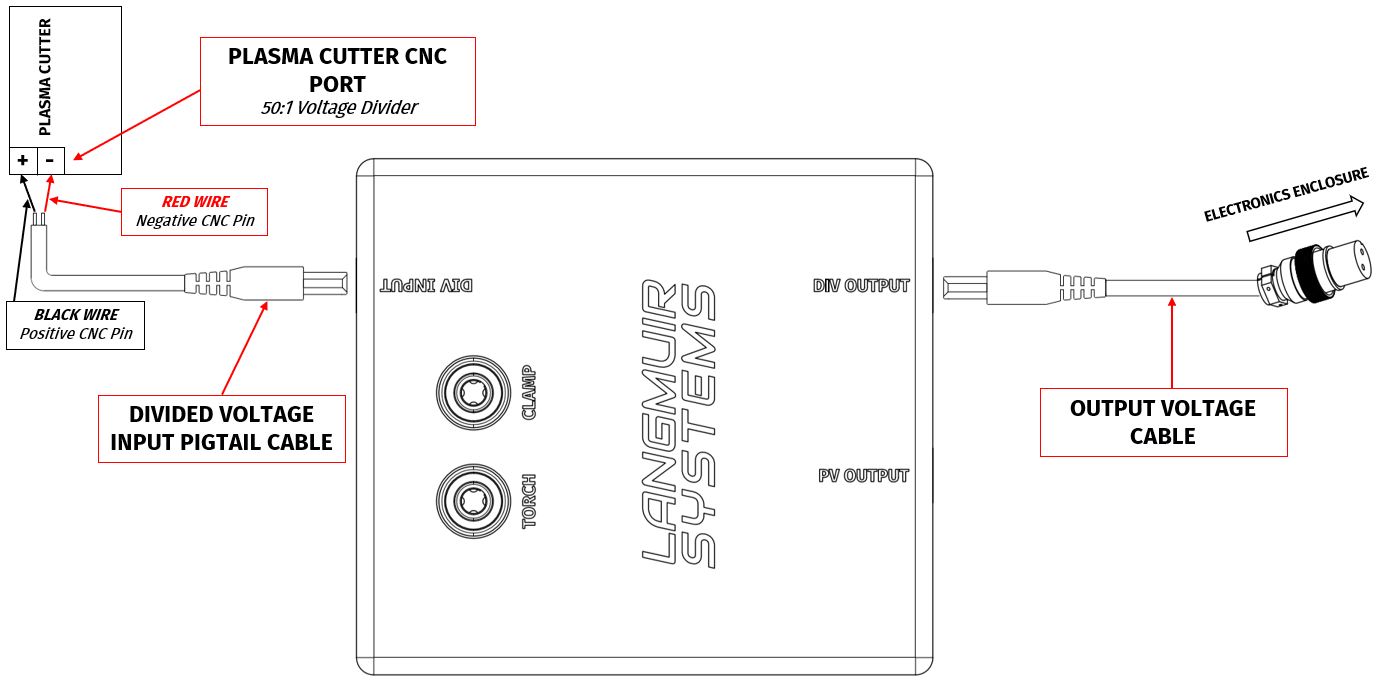

Divided Voltage Input Pigtail Cable?

Or since I have I have done raw voltage I only do one?

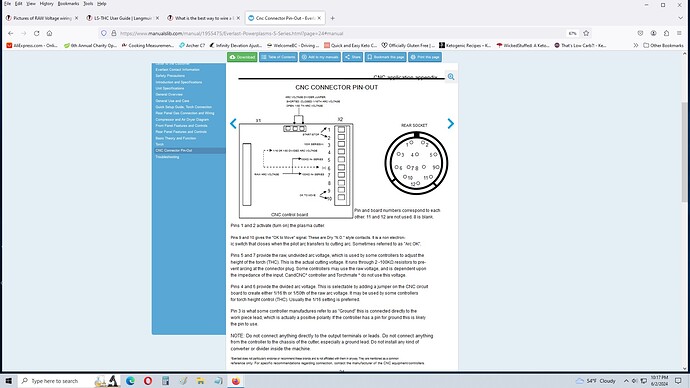

I have solder pins 4 and 6 to the cnc cable plug that hooks into the the back of the everlast cnc port. Is this correct?

I have pulled the jumper to set it to 50:1 also.

Thanks to everyone that reply to this thread !!!

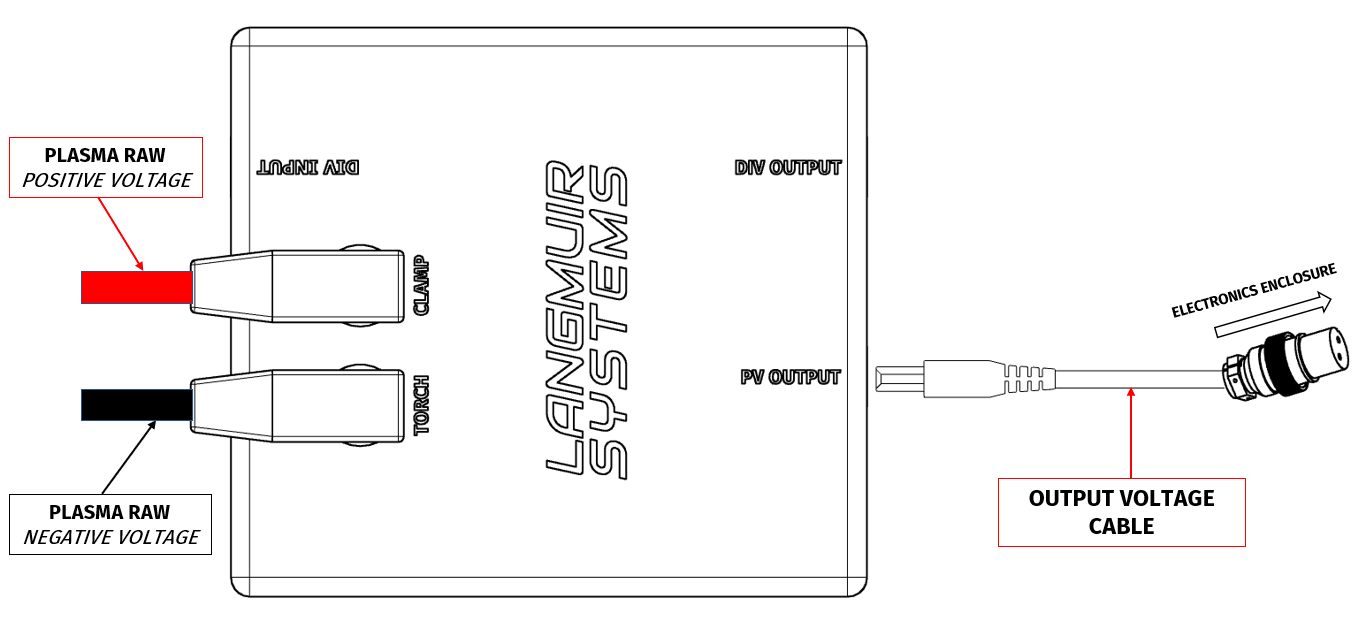

If you have already wired to the inside of the power unit, then connect to the RAW voltage on the VIM module.

All you need is pins 1 and 2 from the CPC port to fire the torch.

IF YOU HAVE THE MACHINE TORCH, then I would just do everything from the CPC port, using the CPC cable and get set up for 50:1, and not tap into the lugs for the work and torch leads.

If all you have is the hand torch, then you must open the case and wire direct to the Torch and Work lead studs.

Since you are wired to the raw voltage inside the machine, you only need the voltage output cable from the “PV output” port on the VIM to the THC port on the electronics enclosure. The two DIV ports are not used with raw voltage.

In order to fire the torch, you need a wire that goes from pins 1&2(polarity doesn’t matter) on the CNC port to the “torch on/off” port on the electronics enclosure.

Is this for a hand held torch that came with the plasma cutter or a machine torch that I have to purchase?

Divided Voltage Input Pigtail Cable connects to pins 1&2 on the cnc plug port and to the DIV input?

Or I don’t use the Divided Voltage Input Pigtail Cable with a hand held torch?

Thanks again, just don’t want to fry anything.

You don’t need the divided voltage wires. It’s either raw or divided, never both.

The torch on/off connection is required for all torches. It’s the only way for the table controller to tell the plasma cutter to fire the torch.

There should be a long cable with a barrel connector on one end and two white wires with red spade plugs on the other end. Cut those spade connectors off and solder one of them to pin 1 and the other to pin 2 on the CNC connector. The barrel connector the gets plugged into the “torch on/off” port on the electronics enclosure on the table.

it’s not recommended to use the divided voltage circuit via the cnc port on the everlast cutter due to them not outputting a true 50:1 ratio.

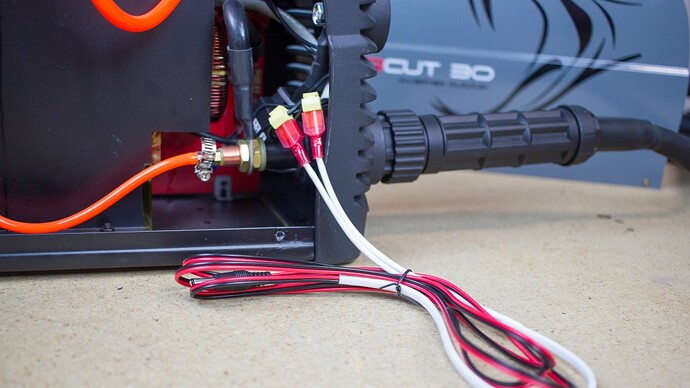

So I should connect it to the torch like in this picture? or what do you recommend?

Thanks again for everyone’s help.

The wire in that picture is the torch on/off wire.

If you connected to raw voltage the same way as the first pictures you posted, that’s the correct way to connect to raw voltage.

Voltage connection for the THC and wiring for firing the torch are two separate things.

Below is all of the wiring that you need to do :

Wire the raw voltage cables in the same way that it is in the pictures on your first post.

Plug those into the color coded ports on the face of the VIM.

Then connect a wire from the “PV output” port on the VIM to the port marked “THC” on the electronics enclosure on the table.

Those are the only wires that go to the VIM.

Locate the wire with a barrel connector on one end and the two white wires on the other end. Solder one of those wires to pin 1 on the CNC connector and the other to pin 2 on the CNC connector.

Plug the barrel connector end of that wire into the “torch on/off” port on the electronics enclosure.

That’s all of the wires that are necessary to make the plasma cutter with with the table and THC.

The only other wire is the IHS wires that connect to the two wires on the back of the Z axis and get plugged into the “IHS” port on the electronics enclosure.

Yes you can hook the torch trigger/on-off wires there. Just make sure they are hooked to the wires from pin 1 and pin 9 of the connector. I don’t like scotch locks but if that is what you want to use so be it.

Thanks again everyone.

So now I did a THC control test and have 0.0V in green on step 3.

The torch fires but the result was 0.0v on step 5.

Should I rewire everything to the CNC port on the back of the plasma machine or do all the troubleshooting in the guide?

Has anyone run into this problem before?

Before you do all that, make sure you have it wired correctly.

Red wire goes to the work (ground) clamp lug. Black wire to the torch lug. Reversed polarity will show zero volts. You can safely switch the plugs on the front of the VIM to test.

Output from the VIM must be in the PV output. It won’t work if it’s on the DIV output.

i think you’re getting your wiring confused.

only use the cnc port for the torch on/off, pins 1/2. don’t connect anything else to it.

use raw voltage from inside the cutter as illustrated on pics 3 and 4 of the post you tagged, then those leads connect to the VIM box like in the first pic. Use the PV output from the VIM box to the THC input port on the langmuir control box.

Well I follow the troubleshooting flow chart and will have to contact support with a suspected VIM box Failure.

Thanks again for everyone help.

Waiting on my Crossfire Pro to be delivered. I previously had a Crossfire connected to my Everlast 60S with no THC. Why not use Pins 5 and 7 from the Everlast since those are raw undivided voltage instead of 4 and 6 which is divided voltage if it’s not truly 50:1?

Just wire the THC to the inside of the plasma cutter for best results. Don’t use the CNC port.

Because it’s most likely filtered as well. You want straight unfiltered raw voltage and connecting to the lugs will give you that. the VIM box will do the filtering for you.

What might work for one particular plasma table might not work for another. in this case, the cnc port does work well with langmuirs VIM box.

Wire it from inside the machine. Seven hundred of us can’t all be wrong—trust us! ![]() Just go to the top of the page, type in “Everlast Raw Voltage,” and hit the search icon. Bam! You’ll find a hundred reasons to wire it from inside the plasma cutter.

Just go to the top of the page, type in “Everlast Raw Voltage,” and hit the search icon. Bam! You’ll find a hundred reasons to wire it from inside the plasma cutter.