My first real bend I forgot to take pics before I welded it on. It went pretty good for me not perfect but usable.

This was to repair a Fume Collector I bought at auction, that had some dropped on it.

I enjoyed building this tool box train horn set up. I obviously bought a UWS Low profile tool box but I built on to the bottom and recessed the train horns, used an old propane tank for a pressure vessel.

Nice work what is this used for? Scaring people?![]()

ummmmm, maybe!

That is a neat job. And I hope you really enjoy your project. Hmmm Need to get me one built…

I am not quiet finished yet. I do plan on making a cover for the wiring. Also I plan on making another pocket to hold a tire repair kit

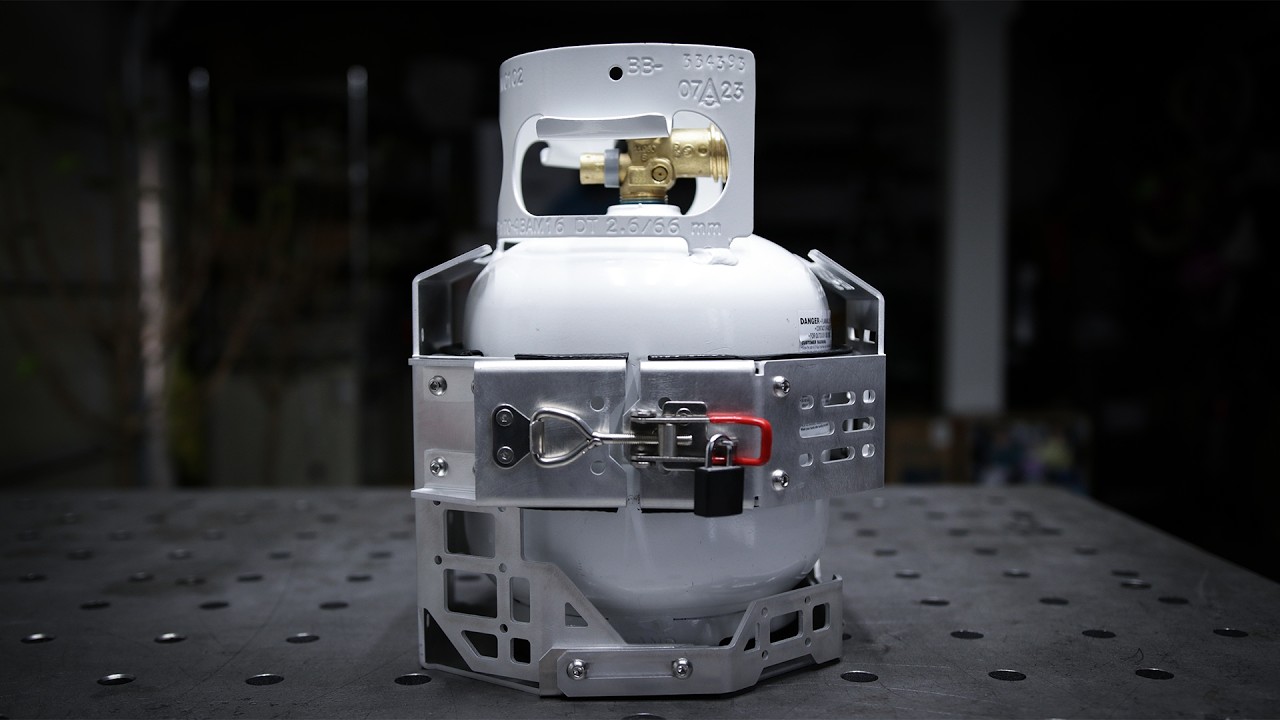

I saw Ratha Sochenda released a video today of a Propane mount Holder and I’m just blown away by the technical mastery on display here at every level. Really inspirational stuff!

I cant draw currently in 3d. I just map it out in my head and make adjustments afterwards. looks neat. I have done some aluminum cutting on my plasma cutter. Needs alot of cleanup. Wish I had a water jet at least.

Great video! Ratha is very talented!

That is an outstanding product AND product video…

Shoutout to Matt.3amcook!

Some really impressive prototyping design work on the Titan.

“Here’s a very simple but functionally effective set of brackets that enable automation to control blast gates on a dust collection system. Utilizes a $18 cylinder, $18 valve, and a few bucks in tubing. Parts took about 2 hours from CAD to prototype. Same process would have taken me a weekend previously. This is only the beginning. :)”

I like it, I’ll have to make one too!

I automated blast gates at my old job, but i used pneumatic switching. My cylinder came down from the top, im not sure but I think our gate would bind if only a cylinder on the side. Mine did not look as professional as yours by any means. Nice job

Shout out to Steve Green with greenworksfab.com for his production work on the Titan!

“The Titan has been very consistent, especially when I bend long seams by cutting the flange with a cut-off wheel and do multiple bends to make one long bend.”

Shoutout to @abelfabparts for this really cool custom punch and die setup! I saw it yesterday and I was really impressed with the design!

“Also made a custom die for a specific bend I need, very happy how easy manual mode was to get setup! Photo attached, still need to work on die a little but surprised how well it worked!”