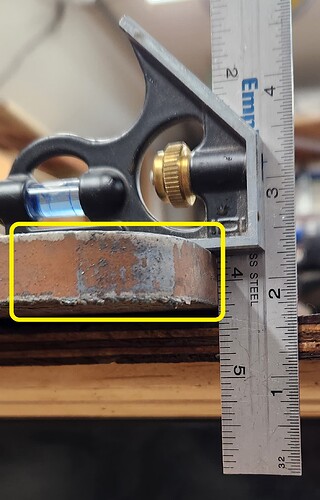

I asked this question because I recently cut some 1/2 inch steel and the cut was so smooth, you would think it was buffed to remove all scratches. Compared to 12 gauge steel when the vertical striations from the plasma stream are still visible.

(Note, the brown coloration, I had thought was rust but it really was not stuck to the metal so I think it was just the suspended rust particles suspended in the water that was left after drying. It rubbed right off.)

What I decided, is that since the “machine” (plasma table) is moving slower, there is less vibration. Perhaps by reducing voltage and speed, I would achieve a smoother finish with other thicknesses of metal.

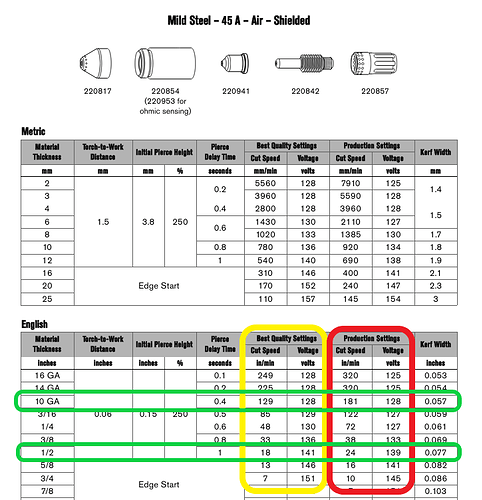

Then I got confused. If you look at the charts for Hypertherm and compared voltage vs speed from the “Quality” and the “Production” columns, some of the figures only involve reducing speed with the voltage changing very little or not at all.

I do understand watts (power) = amperage x volts. Perhaps the same watts are applied in the plasma cutter when you decrease volts there is an increase of amps? But, NO…I set the amps on the front of the machine so that is not changing.

I know I am showing my lack of experience with all of this plasma cutting. But it still puzzles me that you can just decrease the speed of cut without changing the other parameters and not suffer consequences.

Big question: Is it possible to get as smooth of cut with 12 or 10 gauge as I did with 1/2 inch? (I will need to do more testing as I admit that this was the first cut I have ever done with nominal voltage and I have not cut 12 or 10 gauge with nominal voltage yet.)