Been admiring the many clever approaches some of you have come up with to drain & save the table water, then refill the tables on the XR’ and the pro’s. Wondering if anyone has tried a single 75 gallon storage tank out of an RV on their XR, as they are not cost prohibitive even when new.

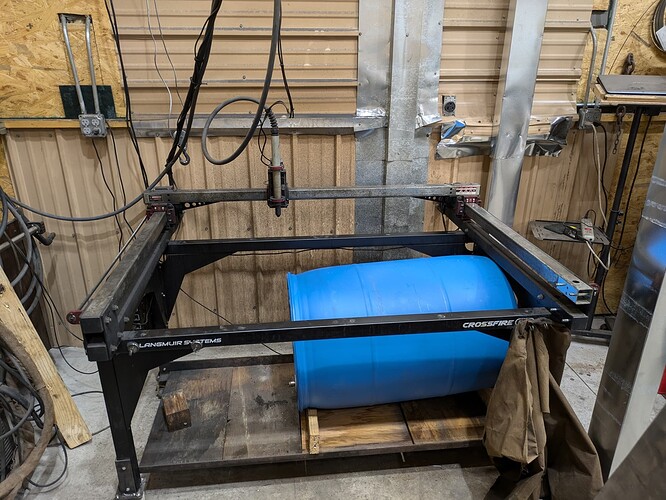

We welded some 3/4" sq tubing across the lower frame and nested two 55* ( edited from 30) gallon plastic barrels connected with 1" PVC and 4 kitchen sink drains in the water table. It has a std plastic canister water filter on drain line and PVC shut off valve. - We up fill with 5 psi air to the barrels having small fitting in each barrel in top bung. It was inexpensive and works well. We have noticed on our sink drains they have a 90 or Tee directly under the drain and any heavy grit exiting the drains wants to lay in the horizontal run between the drains. We may revise to put a Tee with a vertical leg and cap on each drain such that the heavy crud drops into the vertical leg and the horizontal leg wont get crudded up so bad. Similar concept as used for air lines to keep water out of supply lines. I think our work is posted on this forum. Ken in NC USA

I stared a new FB page Autotech to share all my work in many areas 0 posts 0 followers. Lets see what I can do with it, I am not a fan of FB so not sure it’s the right move. Instagram maybe better? I just work… and stay off devices other than cad and manufacturing

vs connecting with social media but it is what it is…

I used a 55 gallon plastic drum, which I found locally for $23. It’s big enough to fill my 4" deep single piece table.

I like the rat… but his machine looks too clean .

I run a barrel system as well for my CFP, but doubt that this 35gal will hold enough for that size of a table…

Yes have been using rv tank for 3 years ,also used table drains as fills , and put in drains in the center of each drain pan .used 3/4 pex fordrains and fills ans a 110 rv water pump to fill

For an alternate opinion, I have found this unnecessary. It’s super cool if you have the time and money, but not needed. I live in Houston, weather wise. I’ve never had the water get gross. It evaporates pretty quickly, so in my case, doesn’t have the chance to get nasty. I throw 2ish cups of Borax in the water every so often.

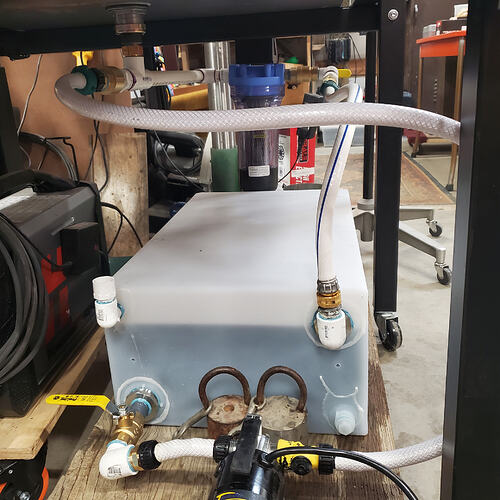

So you guys using the enclosed RV water tanks, do you have them vented? Seems like when draining the water or air would bubble back up in the table other wise.

I’m am also trying to figure out how you guys are going from the sink drain to smaller PVC pipe or pipe fittings? Maybe I need to look at a different brand of sink drain.

I really like this setup, but I’m thinking a 13 gal RV water tank for my little Cross Fire table.

I have a vent pipe on my tank.

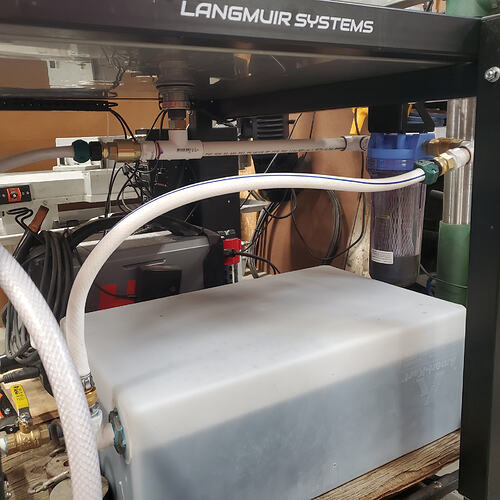

I’m not running a sink drain. I had a custom water pan cut and bent up then I welded the corner seams. I have a centralized single drain that uses a brass bulkhead fitting meant for boat hulls ( Amazon.com ), that was turned down to minimize the flange height, and sealed with marine sealant against the table.

As for venting, the return hose hole into the tank is ragged / large enough that air can vent out as the coolant returns, but if memory serves, I also drilled a small hole above the bung to allow venting.

Use whatever size tank you want, just make sure you allow for enough space that you don’t overflow / leak out of whatever return you use. Also, since this picture was taken, I have added an extra 20 micron woven filter as a “polishing” filter just before the coolant returns to the tank to remove any fine particulate that was collecting in the bottom of my reservoir tank.

Thanks for the info Andy, I think when my small table is full it holds 9 gal. that’s way I was thinking the 13 gal tank will be plenty.

I made an adapter for my sink drain, and since I can’t make pipe thread I made it for garden hose thread. From there I can go to 1” pipe thread and PVC.

A straight pipe thread will work, just make sure you use a hardening sealer. Loctite’s 577 is good stuff for filling those gaps on low pressure applications..

I have my storage tank installed and working. Until I build a platform / shelf under the table I have the tank and plasma cutter on little carts, and everything is working great! I probably could have used a smaller filter, but it’s fine. I 3D printed a bracket to hang it.

but but but…..

you have a plasma cutter?