I haven’t kept the best track that’s one of the reasons why I switch it out every other time.

if I was to guess two sessions maybe 800-1200’ feet of cutting on 14 ga . A hour to a hour and a half torch ON time.

I am still in the amateur crowd myself.

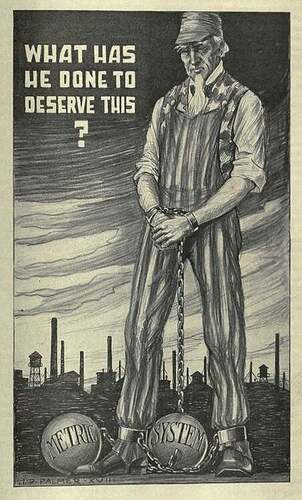

Your regional relative humidity will vary and it also depends how much moisture you mop up before the desiccant cell. But this is good opportunity to you my favorite metric metric propaganda post.

“What has he done to deserve this?”

2 Likes

My dad and I bought it for the same reason and are looking to make some 1/2 inch pieces as well. So definitely want to manage it the best we can. Little pic of the first project I ran over the weekend with it. Looking forward to getting some more cut time on it

4 Likes

Something to mention if you have rust flakes or impurities on the surface,as your torch goes over that area it will mess with your cut quality.

But i see all the cpmments on air,dry,cfm etc.

But i would look more to air volume. That is do you have restrictions, like a small hose inside the plasma cutter,or the barbed filling inside the cutter or even the selenoid restriction.

Air pressure or cfm is not as important as sir volume.

While I agree with this statement in principle, unless you have a volumetric flow meter inline in your system then air pressure is the only gauge you have to setting the proper air flow. If everything in your plasma cutter is operating the way the manufacturer designed, then maintaining the recommended air pressure going into the back of your machine will produce the air volume the plasma cutter needs according to the manufacturer. The manufacturer will have taken into account all the restrictions and other variables inside the cutter. So as long as your air system can maintain that recommended air pressure at the back of the cutter while cutting, then by definition it is supplying the correct volume of air.

Sorry if you took my opinion incorrectly.

I’m not the expert.

I had an issue that it was impacting.

A work around the check it for me was for example setting the compressor out put at 50psi and if your plasma cutter has a button to test air with firing just have to trigger the torch and at exactly the same time watch your pressure drop the initial drop around 6 and then hold pressure at a 4psi or 46psi.

As i said I’m no expert on your or any cutter but it could be helpful

Ernie

1 Like