As a gag gift for my brother-in-law’s 50th Birthday AND yet another reason to use my CrossFire ![]() I decided that a variation of the ‘F-Bomb’ would be in order. In this particular case, the ‘F’ stands for ‘Fifty’!

I decided that a variation of the ‘F-Bomb’ would be in order. In this particular case, the ‘F’ stands for ‘Fifty’!

Thats cool, Is the lettering laser etched on to it or?

Looks like it. Using Dry Moly even ![]() (Cermark is usually blacker.)

(Cermark is usually blacker.)

That’s hard to say… I used my laser engraver (40W) to blast the printing on to the surface that was ‘painted’ with CNC Moly Dry Lubricant. Apparently the Molydenum melts and bonds to the Stainless Steel surface. You can sort of feel that the letters are raised, but they don’t scrub off with acetone and a brush. To be honest, I’d didn’t try to see if I could wear it off ![]()

What laser engraver do you have? I’ve been looking for one to put my logo on parts.

Correct. It’s not “engraved” as much as “marked” when lasering with Moly (or Cermark). You’re basically doing what a laser printer does to paper - fusing the Moly to the steel. It’s extremely hard wearing because it fuses down into the grain of the steel.

I’ve tried getting it off with wire wheels, flap wheels and even grinders. It only “goes away” when the steel it’s embedded in is removed. In the process it will spread in the grinding particles and smear into surrounding steel.

I usually start over or paint the steel black and turn it over. I’ve not found a clean mechanical or solvent based way to remove it.

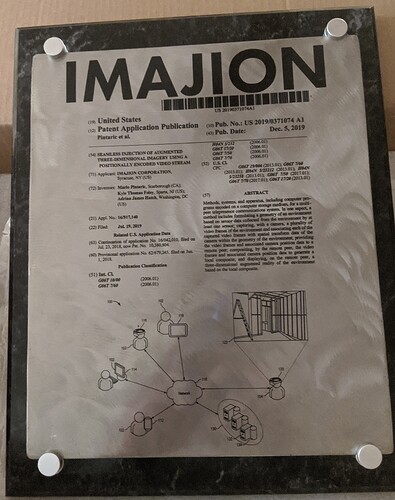

Here’s my latest use of laser “engraved” stainless steel (cut on the Crossfire) using Cermark (a custom formulation for laser marking similar to dry moly lube at only 10X the price ![]() ).

).

A cheap Chinese 40W laser that are a dime a dozen on eBay (well, they used to be low $300s, but now that the govmint is taking good care of us they’re a bit over $400…). Keyword to look for is ‘K40’, that references a basic 40W, bench top laser (I think ‘benchtop’ is a stretch, however, because it will take up your whole bench. I have mine on a Rubbermaid Cart.).

The thing is, these are projects unto themselves and it took me a few months to get this to my liking. I’m a retired electronic engineer with HW & SW background so it was relatively easy for me to gut the electronics and replace it with something that did what I wanted, when I wanted… Lots of good advice on the web on how to get one of these things useful, but it’s not for the timid…

Update: I found that this site provides a good idea of what’s involved in making a K40 laser useful: https://www.wargaming3d.com/2019/09/06/chinese-k40-laser-cutters-for-wargaming/

He provides good summaries and, best of all, lots of links to useful (and necessary) information.

Very interesting Im telling myself as i type I dont need one but I kinda want one.

That’s a nice gift as well, a stainless steel copy of a patent! Hmmmm, maybe I’ll try that. What gauge steel is that example?

@jamesdhatch I’m super interested in this process if you could elaborate on how it’s done and what I need to do it here that would be great!

I started with one of those. You’re right, it’s a project into itself but you can mod the hell out of them. (You kind of have to, in their native state they’re not the safest things around ![]() ).

).

It’s 11ga stainless steel. Aluminum standoffs. I painted the back black & the front has a clear coat. It’s my version of a “gold record” for geeks. My son was awarded it last year for some really kickbutt augmented reality stuff he did (he’s the founder & CTO of Imajion). I figured he ought to get a gold record to hang on his wall ![]()

Indeed! Those of us who got patents, while at companies other than our own, a frame with a paper copy of the patent was about all we got ![]()

I had a tight deadline for this one so ran with something that worked, but it would seem worthwhile pursuing what kind of resolution I can get with this ‘printing’ technique. Looks like you did very well.

I have used dry moly - $10 a can is pretty compelling. It is a bit grayer than Cermark but that runs $100 a can. Lasermark is halfway in between & supposed to be the guy who invented Cermark and just as black.

I started with a K40, moved to a 60W Redsail and then a pre-release & ultimately a Glowforge Pro. It’s neat being able to mix the tools & projects.

We should probably break this off to a new thread, but I was drawn to Glowforge until it seemed that they were not delivering on their promise and I backed off. It seemed like they had the right turnkey/low cost perspective, but it was taking them too too long to deliver. So, my question is, are you happy with what you have now, especially having gone through the ‘burning coals’ of K40?

UPDATE: BTW, I wouldn’t consider $100 a can too expensive a material for a child of mine. No demerits on that one!

Yeah it was worth it. Did take them a long time to get the thing to production. It helped a bit because after the first 6 months of delays they picked me to test a pre-release unit. Then I knew it was real and just a matter of time. Since their early buyer money was escrowed it wasn’t a huge risk.

It’s sort of like a Tesla. Every couple of months something else cool can be done with it because the software control is all in the cloud. They update your firmware & the thing is 4 times as fast. Update it again and spotty WiFi connections work. Another update and it does variable power/speed on turns to prevent overburn. I’m testing something for them now I would argue is magic. Honest I was floored when I tried it and it worked.

But, they’re still figuring out how to play like a big company - support can be slow, non-warranty repairs are a mystery (it gets fixed but you never know what was broken), etc.

That’s part of why I am not all twisted up about Langmuir - I’ve had serious late delivery on a 4K purchase from a startup ![]() Langmuir is doing a super job I think. Remember Pebble watches? Or Oculus VR headsets?

Langmuir is doing a super job I think. Remember Pebble watches? Or Oculus VR headsets?

Well, you really had me going until you mentioned Pebble watches! I have the original… sitting on the bookcase in my office. But, thanks. Very inspirational and thanks for the perspective on Glowforge, I’m glad they’re finally working out.

I’m also glad I stuck with my little K40 s__tbox. It’sworking pretty well now - doesn’t look anything like it did in the beginning.

They’re actually great machines. The CoHesion project and other open source and user-led efforts to make it better are great. It lets you start with an operating machine that you can than turn into a really good one without going the build from scratch route.

I’ve been surprised that the Muse & the Dremel haven’t taken off yet. It’s been 3 or 4 years - they should have been pretty popular by now with the Glowforge delivery delays and now their past few years of shipping at volume. Surprised the competition isn’t making waves.

Moved thread to uncattegorized category.