Greetings all. When I load my part in and it goes for its first cut it will fire, burn through the plate and when it starts to move it proceeds to not cut all the way through then blows out and stops the program. Attached below are images of the issue I am having right now. To give information on what I have set up in SheetCam is a set of tools that I have found through these forums, and I tweaked it to specs for 16ga that was also in another form. As it sits my tool in SheetCam is set at Kerf 0.026", feed rate 70ipm, pierce delay 0.25", pierce height 0.15", plunge rate 50ipm and cut height 0.073". I also have my Razorweld 45 set to 28 amps, and 90psi.

Also have my ground clamped to my plate to ensure a good ground.

Are your Pierce and Cut heights measured, or the values you have input into SheetCAM? By default, the Post Processor will add an additional .020" to these values.

We also run a RazorWeld 45. For 16ga, I have it maxed at 45A, kerf of .047" and cutting at 180 IPM. Pierce delay of .5 sec. (Pierce height of .150" and cut height of .060".)

I did not know that it would add .20 to it. Good to know. Unfortunately I just ran the part again with everything set to how you had it listed and same results.

Any chance you can upload the G-Code / .tap here? There might be a few crumbs of information within…

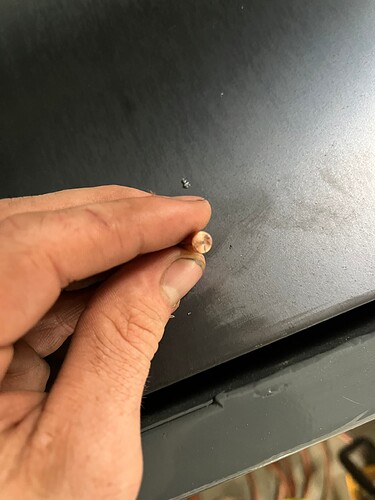

From the picture the torch height is to high and the consumables may also be bad.

Is it maintaining 90psi while cutting?

+1

@Coopersmetalwork consumables will be ruined quickly by low air pressure, water and incorrect cut height .

Is the cut height of 0.073 to high? I haven’t checked to see but it should be due to my compressor being able to handle constant use and stay around 100psi. I don’t believe my consumables are bad seeing as it’s cut a total of 6" but here is what they look like.

.

fuel can for the last time 2.tap (4.5 KB)

Check that you have enough air at the machine during the cut.

Dynamic Air Flow has real meaning Static air flow does not .

It’s a bit higher than I cut for 16 gauge, but I am not using RW. I successfully cut 16 gauge at 0.051".

Looking thru your .tap file, it appears you didn’t adjust for the .020" SheetCAM adds. That would bring your pierce to .170" and cut height to .080". Was the pic of the 2nd cut with the adjusted settings done at 45A? The pierce and kerf look rather small.

Resolved! my compressor was in fact not enough to maintain 90psi while cutting. Got a new one and its cutting great now! still need to tweak it a bit but good enough for the first part. thank you for the advice.

now you need to watch the moisture issues…moisture is a devel to deal with and destroys tips fast