TFS just posted this

My business partner just linked this to me. I think he wants us to try it.

Very clever idea!

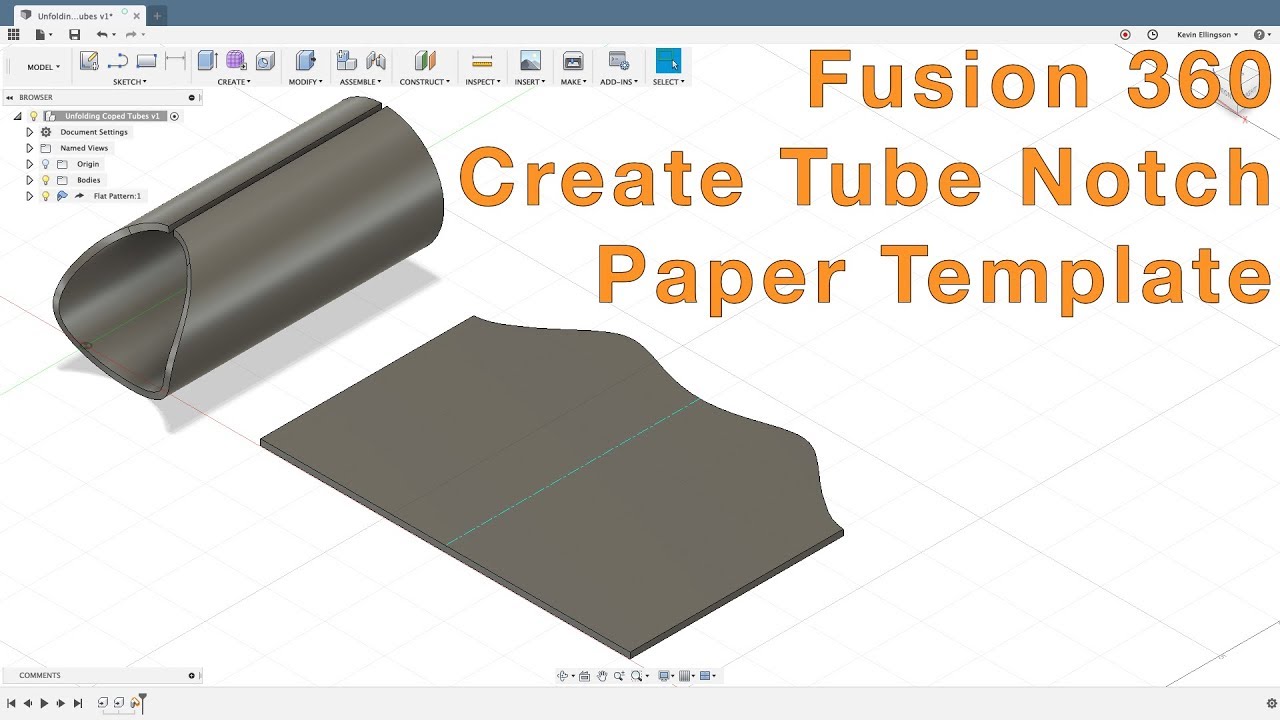

Interesting way that he created the profiles in onshape. I don’t think there is an equivalent in fusion. I’m probably wrong I need to look into this a little bit more but I’m out walking my dog.

On my crossfire pro it won’t be simple to attach those wheels to the x-axis gantry. It’ll be a little bit of a competition I believe with people here on a clever way of implementing this approach.

I like that there is a 1:1 relationship between Y axis and distance around the tube. You could cut practically any opening into that round tube as long as there was no slippage.

It does have an entire sheet metal environment where you can unwrap any kind of profile. Sheet metal flat pattern.

I have my og crossfire still and may reporpose it as a tube notcher.

His slit method results in a split tube (non-flat) surface. Fusion’s sheet metal tool won’t let you select a non-flat surface to flatten from. I’ve seen a process where you split a tube, then extrude a small flat section, then use that flat section to flatten a curved surface. This works fine.

Yeah, that’s the video I saw several months ago. Thanks for finding it.

Tin made a video sometime ago for a circular fire-pit. It uses a small section that is not curved and then you create the curved portion as a flange. It is done in the sheet metal environment and by having the small section, it acts as the “stationary” portion for “unfolding”. That way you can make sketches on the unfolded portion vs the flat pattern. Perhaps that could be done with the pipe size of metal flange.

Here is where that video was:

Tin, do you still have that video?

This is what I said.

I see that now. I did not read that!!! ![]()

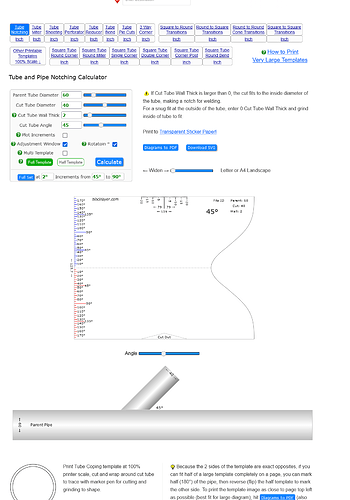

I found an interesting website that will print out a paper template for you.

This pattern could be traced in Fusion on the flat pattern.

And there are some 3D printable sleeves that you can mark your pipe with a marking pen.

No worries, thanks for the tube link.