After the first profile is cut, the torch moves to the second profile. It goes through the torch height control cycle on the second profile and the torch starts. It stays stationary for a bit then the torch turns off and the torch does not move. an error pops up and states the pierce delay in the program could be too short or too long. I’ve tried several different settings on the pierce delay to no avail. I’m using the Crossfire XR and Everlast 82i for the first time after assembly.

Morning welcome to the forum.

What PSI are you running at the plasma?

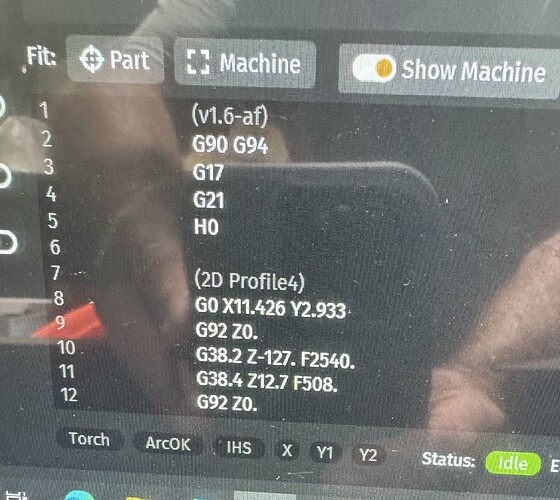

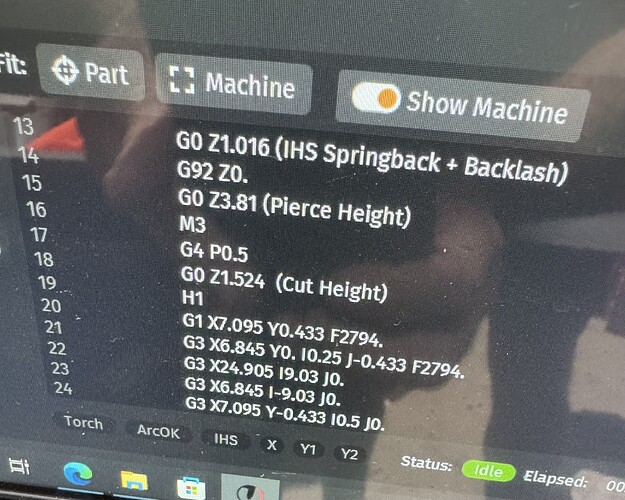

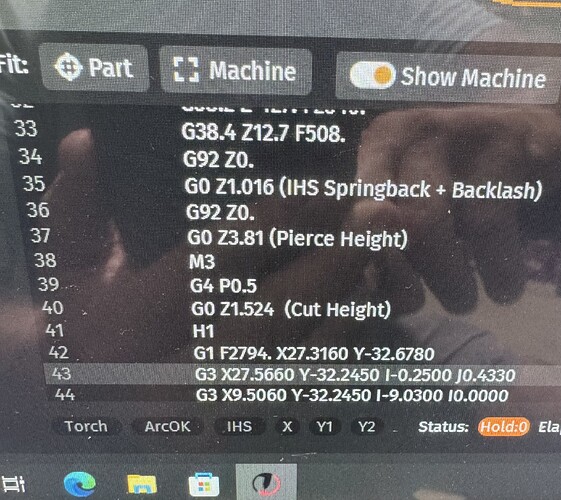

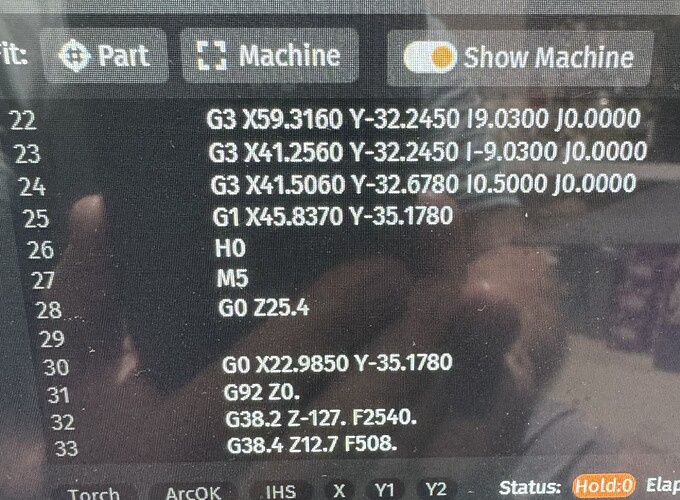

Open the g code with a text editor like notepad and copy and paste the first 20 lines in a post on this thread. That will make it easier to see if this is a programming issue or something else.

Welcome to the community!

What thickness metal are you cutting and what were the pierce delays you tried?

The air pressure I am using is 64 psi

16ga .5sec

I also tried anywhere from .1 sec to 1 sec

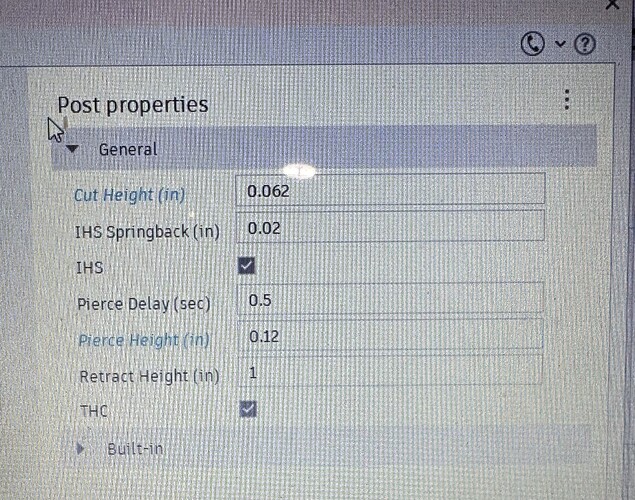

Air pressure must be set to a minimum of 75 psi. The torch will not fire consistently at 65 psi, as it requires the proper air pressure to ignite the pilot arc. Set you pierce height to.12 you have it set .81, set the cut height to .062.

Is the Everlast wired to RAW voltage?Unsupported Browser | Adobe Acrobat

Here is a Everlast 82i cut chart

Unsupported Browser | Adobe Acrobat

Yes, it is wired to raw voltage. Thanks for the info. I will make the changes and get back to you with the results.

A note to add is that the torch stayed on after cutting profile one and moving to profile too

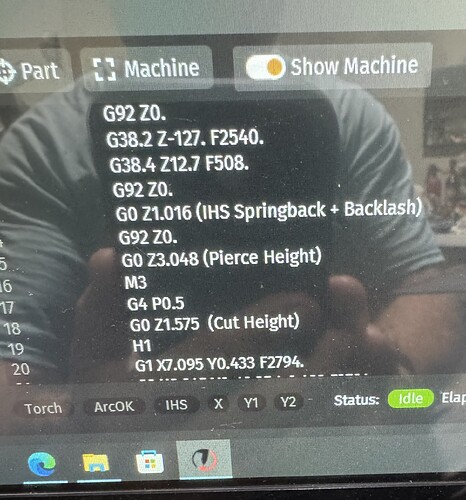

After entering the settings you suggested in fusion 360 post, then transferring the G code file to fire control, you can see it enter a different cut height and pierce height numbers.

After making these changes, the torch went to profile one and went through the torch height control, but the torch did not fire… The error says THC unit did not detect arc voltage when the torch was commanded to fire. Your program was paused.

I don’t understand that. Email Langmuir to see if it’s a bug. Mine are exactly what Fusion has set them.

All of your units are in metric in the code. You must have selected metric output in Fusion and it’s converting all of your values to metric in the code.

The outgoing units were in millimeters and I was working in inches. Now the G code reflects the correct numbers and units. Now the unit is just not firing off when commanded to.

That was the case. The outgoing units were in millimeters. Now the numbers in G code and fire control reflect the same as in 360.

Try setting your air this way. Air to the regulator 100 to 120psi, turn the regulator all the way down till it reads 0. turn it up some and set your cutter to air check, then turn it till it reads 75psi, turn off air check.